Maintaining your chain saw in top condition is crucial for both performance and longevity. Knowing the layout of internal components, as well as how each part functions, can make repairs and routine maintenance much easier. A comprehensive visual guide is one of the best tools you can have when servicing your equipment.

Whether you’re a professional or an enthusiast, understanding the structure and organization of your machine ensures that every task, from simple maintenance to complex repairs, can be handled with confidence. A clear reference to the various parts and their connections saves time and prevents mistakes.

By using a detailed reference, you can identify and address any issues more effectively. Familiarizing yourself with each individual component can help you diagnose problems quickly and accurately, ensuring that your equipment operates safely and efficiently.

Complete Guide to Chain Saw Components

Understanding the internal structure of a chain saw is essential for anyone looking to perform maintenance or repairs. Every piece plays a specific role in the overall function of the tool, and being familiar with these components can significantly reduce the time spent on troubleshooting or disassembly. This guide aims to provide a comprehensive overview of the key elements within the machine and their functions, helping you keep your equipment in optimal condition.

Key Elements of the Machine

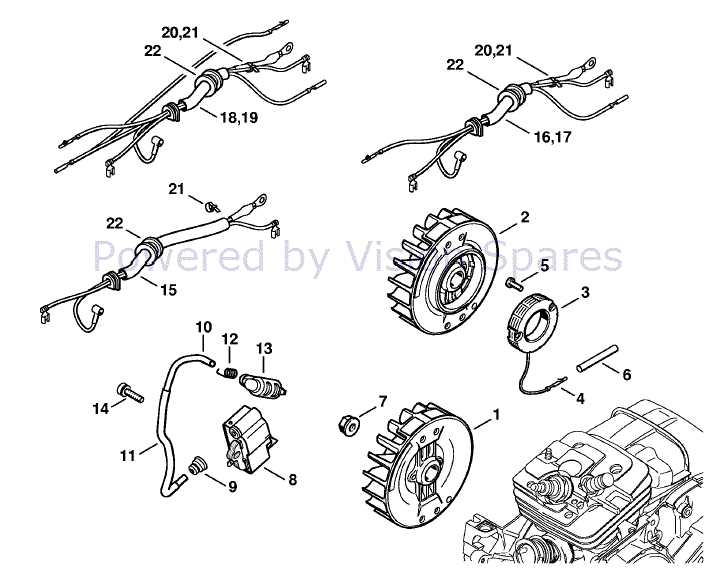

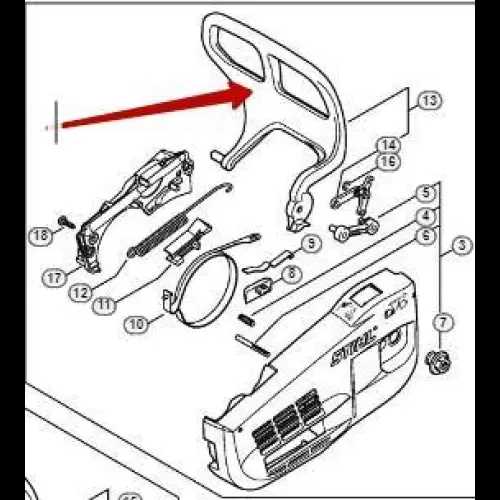

The engine, fuel system, and drive mechanism are the core components that ensure your chain saw operates smoothly. The engine, for instance, powers the saw’s operation, while the fuel system ensures proper combustion. The drive system, which includes the clutch and sprocket, transmits power to the chain, enabling the cutting action. Each of these systems must work in harmony for the tool to function effectively, and understanding their role is the first step in maintaining proper performance.

Commonly Replaced Components

Over time, certain components wear down or require replacement due to heavy use. These include the air filter, spark plug, and the chain itself. While the chain is easily replaceable, other elements such as the air filter or spark plug may require more frequent attention. Regular inspections of these items can prevent larger issues and extend the life of your equipment. Having a clear visual reference for these components makes it easier to identify when a replacement is necessary.

How to Download the Chain Saw Schematic

Accessing a detailed schematic of your chain saw is essential for efficient maintenance and repairs. It allows you to view the full layout of internal components and identify each part’s function. Having a digital version of the schematic on hand makes it easier to consult whenever needed, without the risk of losing physical copies.

To obtain this reference, start by visiting the manufacturer’s official website or trusted third-party sites that specialize in outdoor equipment. These platforms usually offer a secure way to download the file directly to your device. In most cases, you can download the schematic for free, but it may be necessary to create an account or provide product details to access the material.

Once downloaded, you can easily view the schematic on your computer or mobile device. Ensure that you store the file in a location where it can be easily accessed during future maintenance tasks. This reference will serve as a valuable tool for identifying parts, troubleshooting, or following repair procedures accurately.

Understanding Chain Saw Component Functions

Each component of a chain saw serves a distinct purpose, contributing to its overall performance and efficiency. Knowing how these parts interact can help users maintain their equipment and troubleshoot problems more effectively. Understanding the function of each part ensures that the tool operates safely and at peak performance, reducing the likelihood of costly repairs or breakdowns.

The engine is the heart of the machine, generating the power necessary to drive the cutting chain. The fuel system, including the carburetor and fuel lines, ensures the proper mixture of air and fuel for combustion, allowing the engine to run smoothly. The clutch and sprocket system then transfers that power to the chain, enabling it to cut through wood efficiently. Each part must work in harmony to provide consistent, reliable performance.

Additionally, smaller components like the air filter and spark plug are crucial in maintaining engine efficiency. The air filter prevents debris from entering the engine, while the spark plug ensures reliable ignition. Regular inspection and replacement of these parts are essential for preventing performance issues and ensuring the tool functions as expected.