Maintaining and repairing your outdoor equipment requires a clear understanding of its individual components and how they fit together. Whether you’re a seasoned professional or a DIY enthusiast, knowing the structure and functioning of the machine can save time and prevent costly mistakes. This guide provides a comprehensive overview of the critical elements that make up your tool, helping you navigate through any repair or replacement process efficiently.

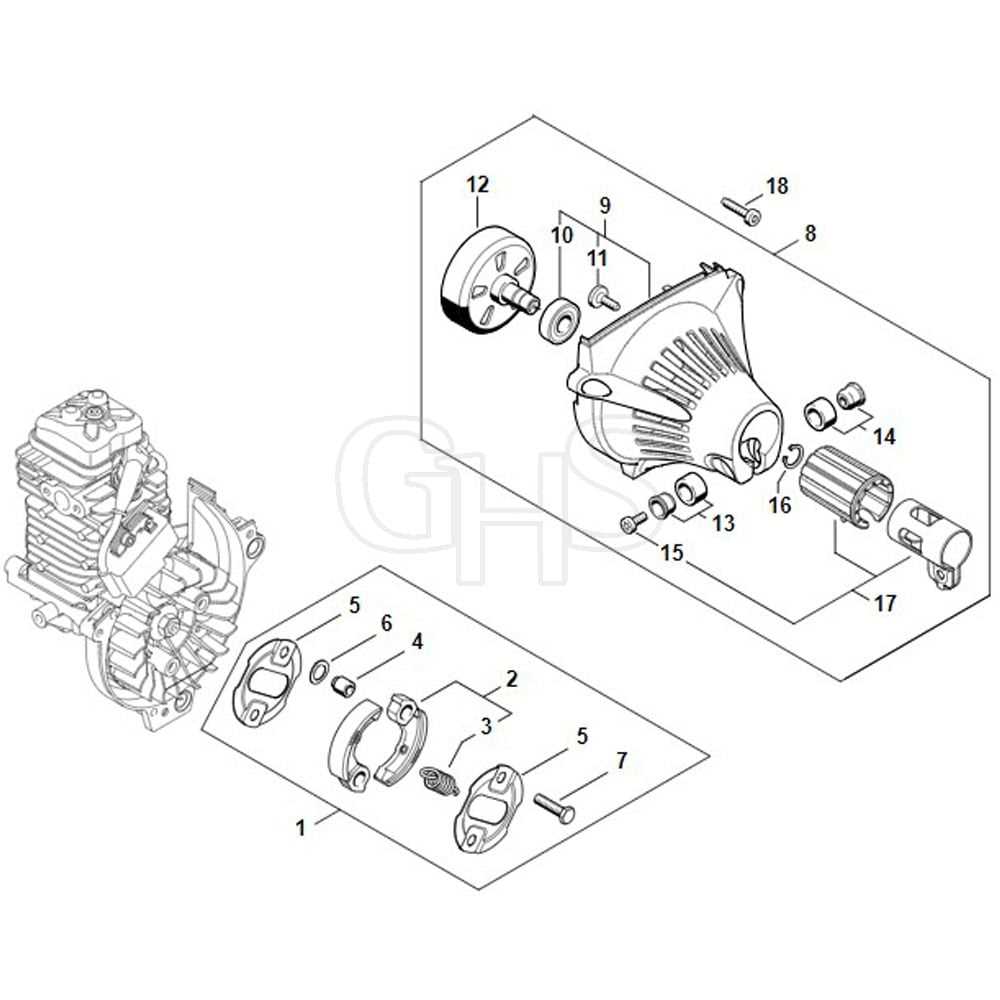

Having a visual reference for each part can simplify troubleshooting and ensure that you’re using the correct components for any repair work. By breaking down the key elements of the device, you’ll be able to recognize the right items for replacement and avoid potential errors in reassembly. With clear identification, your equipment will remain in top condition for longer periods of time.

Effective maintenance begins with a proper understanding of how the individual pieces contribute to the overall functionality. With the right knowledge, you can handle common issues yourself and keep your tool running smoothly throughout its life.

Understanding the Stihl FS 90 Components

Every tool consists of various essential elements that work together to ensure smooth operation. A clear understanding of each component’s function can help you recognize potential issues, perform repairs, and enhance the longevity of your equipment. This section delves into the crucial components that make up your machine, providing a better grasp of its internal structure and operation.

Key Functional Elements

The primary sections of the tool include the engine, drive system, cutting mechanism, and housing. Each plays a vital role in ensuring performance and safety. The engine provides the necessary power, while the drive system transmits that power to the cutting blade. The housing protects the internal components, preventing damage from external forces and dirt. Understanding how these parts interact will give you a clearer picture of the overall machine’s functionality.

Common Issues and Troubleshooting

Familiarity with the components also aids in identifying common problems. For example, if the machine isn’t starting, it could be a fuel or ignition issue. If performance is lagging, it could indicate a problem with the drive system or a worn-out cutting blade. Knowing the role of each element helps to quickly pinpoint the source of the problem and take corrective action, making maintenance tasks more manageable.

How to Identify Stihl FS 90 Components

Accurately identifying the components of your equipment is a crucial step in maintaining and repairing it. Recognizing each piece, its function, and how it fits into the overall design makes the task of replacement or repair much simpler. This section will guide you through the process of identifying the various elements within your tool, ensuring that you know exactly what you’re dealing with when it’s time for upkeep or fixes.

Step 1: Refer to the User Manual

The user manual is a great starting point for understanding your equipment’s structure. It provides an overview of all the essential elements, along with part numbers and their specific functions. Make sure to check the manual’s visual guides or illustrations for a clear idea of where each component fits. The index or parts list section will be particularly helpful for locating the names and descriptions of each element.

Step 2: Visual Inspection and Labeling

Performing a visual inspection of the tool can help you identify components based on their appearance and functionality. Follow these steps:

- Start by identifying the larger sections, such as the engine and handlebar assembly.

- Look for smaller elements like bolts, springs, and covers that contribute to the tool’s operation.

- Take note of any worn or damaged parts that may need replacement.

- If possible, compare the components with images from a parts catalog to ensure accuracy.

Marking or labeling the parts during this process can make future repairs much more efficient, especially if you need to disassemble the tool for maintenance.

Step-by-Step Guide for Replacing Parts

Replacing faulty or worn-out components in your tool is an essential part of keeping it in good working condition. Whether you’re dealing with a damaged cutting blade, a malfunctioning drive system, or any other issue, following a clear, organized process will ensure that you carry out the task efficiently and correctly. This guide outlines the steps for replacing various components, making the procedure as straightforward as possible.

Step 1: Gather Necessary Tools

Before starting the replacement process, it’s important to gather all the tools you’ll need. Depending on the specific component being replaced, you might require:

- A wrench or screwdriver set

- A replacement component

- Lubricants or cleaning materials

- Protective gloves and eyewear

Having everything within reach will help you avoid interruptions and allow you to focus on the task at hand.

Step 2: Disassemble and Remove the Damaged Component

Carefully disassemble the tool by following the user manual’s guidelines or referring to a detailed illustration. Begin by loosening screws or bolts that secure the damaged part in place. If there are any clips or fasteners, gently remove them. Be mindful of the order in which parts are removed to ensure reassembly is easier. Once you’ve detached the malfunctioning element, set it aside and inspect it to confirm the damage before proceeding.

Step 3: Install the New Component

Position the new part carefully, ensuring it aligns properly with the surrounding components. Secure it by tightening screws or bolts, but be cautious not to overtighten, as this could cause damage. If lubrication is required, apply it according to the manufacturer’s instructions. Once the new part is in place, double-check all connections and ensure everything is properly aligned.

After reassembling the tool, test it briefly to confirm the replacement was successful and that everything is functioning as expected.