Maintaining and repairing machinery requires a clear understanding of its internal structure. Each vehicle is made up of various elements, all working in harmony to ensure smooth operation. Recognizing the function of each part is essential for effective upkeep and efficient repairs.

In this guide, we will explore a detailed overview of the key elements found in classic models, highlighting how they are arranged and interact. Knowing these components and their roles will provide insight into proper maintenance, troubleshooting, and part replacement.

Whether you are a seasoned mechanic or a first-time owner, this resource will help you identify essential components, troubleshoot common issues, and understand the overall setup of the equipment. A clear visualization of how parts are arranged can significantly enhance your ability to manage repairs and prevent future malfunctions.

Essential Components of Ford 8N Tractor

Understanding the fundamental elements of machinery is crucial for proper operation and maintenance. Each model consists of several key systems, each serving a specific function. These systems work together to ensure that the vehicle operates efficiently and reliably over time.

Key Systems and Their Functions

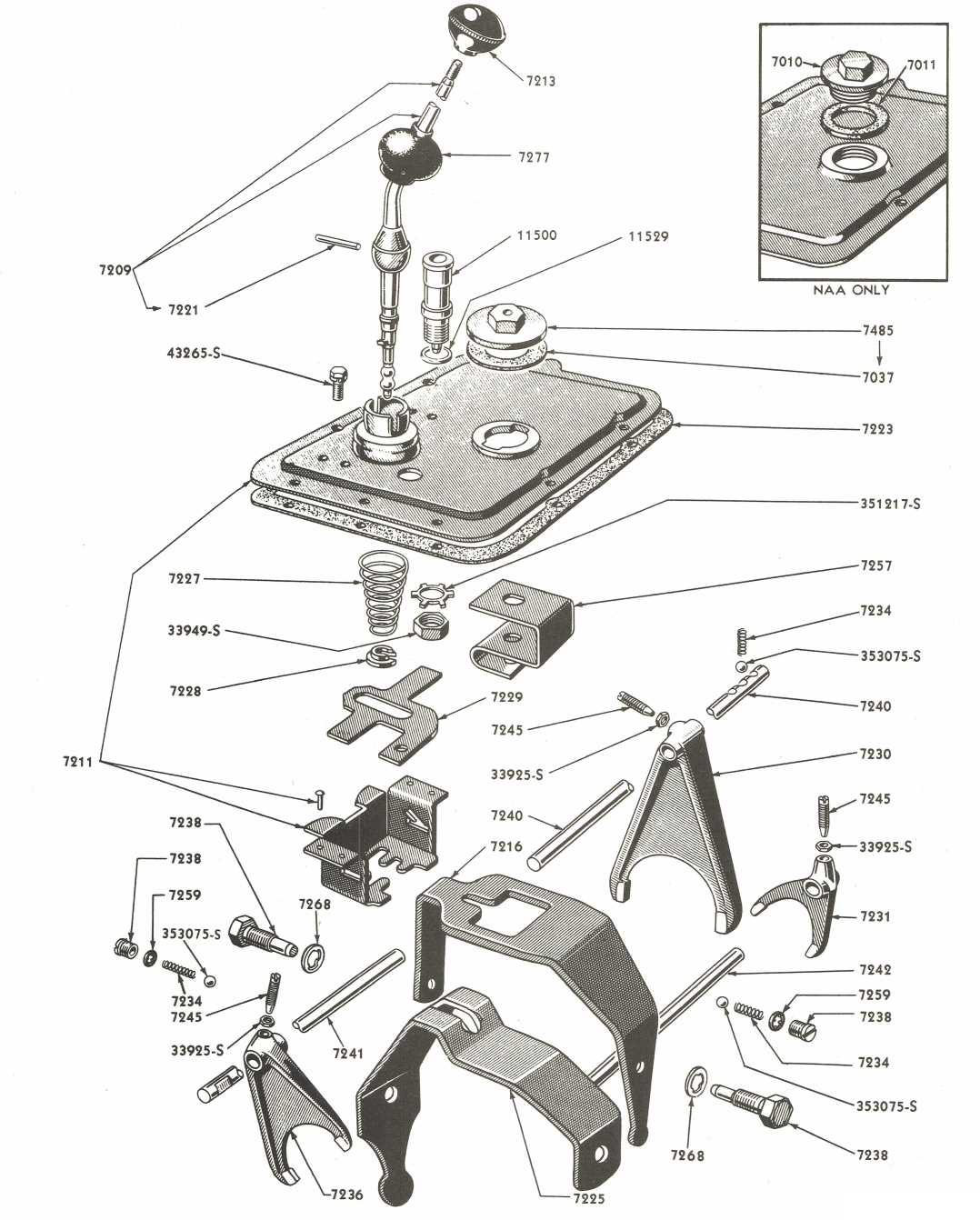

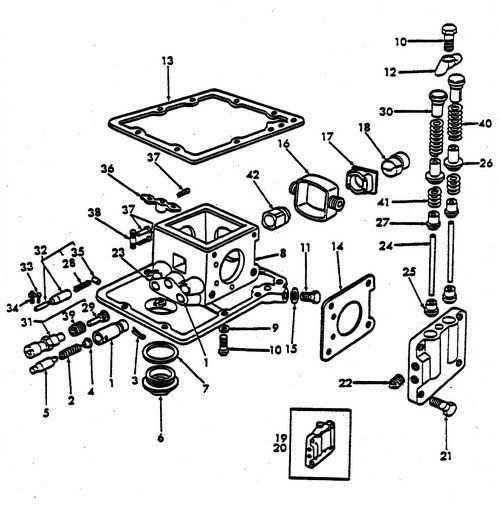

The main systems include the engine, transmission, hydraulic setup, and steering. Each of these components plays a vital role in the performance of the machine. The engine generates the power needed for movement, while the transmission controls speed and direction. The hydraulic system helps manage various functions, such as lifting and controlling attachments, while the steering system ensures precise handling and maneuverability.

Identifying and Maintaining Core Elements

Regular maintenance and familiarity with each component allow for quicker troubleshooting and efficient repairs. For example, recognizing signs of wear in the transmission or hydraulic lines can prevent further damage and improve longevity. By understanding the essential systems and how they interact, owners can ensure their equipment remains in optimal working condition.

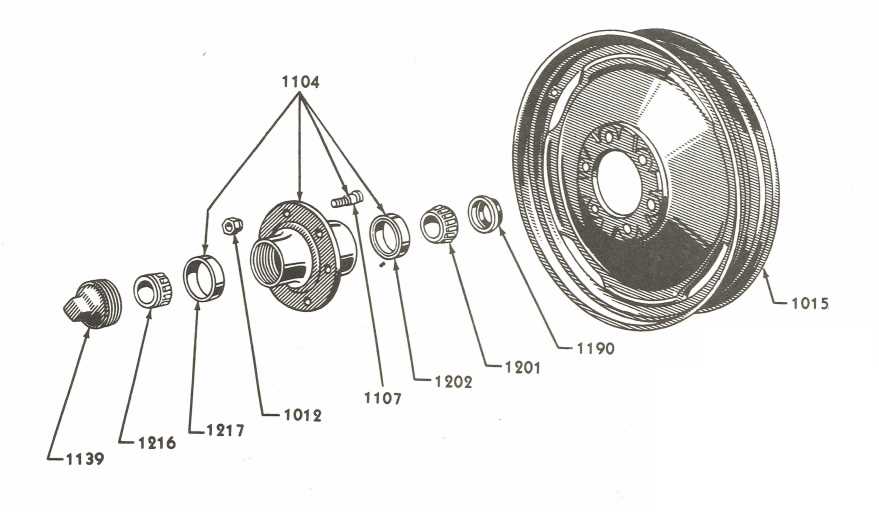

Understanding the Ford 8N Parts Layout

To fully comprehend how a machine operates, it is important to understand the arrangement of its internal components. The layout of these elements determines how they interact and work together to achieve the desired function. Familiarizing oneself with the overall structure allows for easier identification and troubleshooting of issues.

The layout typically begins with the central unit, which contains the engine and transmission. Surrounding this are various auxiliary systems, such as the hydraulic and electrical components, which contribute to the machine’s versatility and operational efficiency. Additionally, critical components like the fuel system, cooling mechanisms, and control elements are strategically placed to ensure optimal performance.

Understanding how these components are arranged aids in proper maintenance. Knowing where each part is located makes inspections and repairs faster and more accurate, ultimately extending the life of the equipment and enhancing its reliability.

How to Identify and Replace Tractor Parts

Recognizing when a component has worn out or malfunctioned is an essential skill for maintaining machinery. The process involves identifying the affected element, sourcing the correct replacement, and performing the replacement procedure. A thorough understanding of each system within the machine aids in this process and ensures repairs are done effectively.

Start by conducting a detailed inspection of the equipment, looking for signs of wear such as unusual noises, leaks, or decreased performance. Once the faulty component is identified, consult a reliable resource to confirm the correct specifications for the replacement. Ensure you select high-quality components to maintain the machine’s reliability and longevity.

After obtaining the appropriate replacement, follow step-by-step instructions for removal and installation. This process often requires basic tools and a careful approach to avoid damaging surrounding systems. Properly securing all connections and calibrating settings will ensure the new part functions as intended, restoring the machine to full operational capacity.