When it comes to maintaining and fixing outdoor machinery, having a clear understanding of its individual components is essential. Proper knowledge of how the parts fit together and function allows for efficient repairs and upkeep, helping to extend the life of your equipment. A detailed breakdown of each element will guide you through any issues you may encounter, ensuring smoother operations in the future.

Knowing your machine’s structure is key to performing successful maintenance. From engine components to smaller, intricate pieces, understanding their layout and how they interact provides the necessary insights to troubleshoot and resolve problems quickly. Identifying wear and tear before it becomes a major issue can save both time and money in the long run.

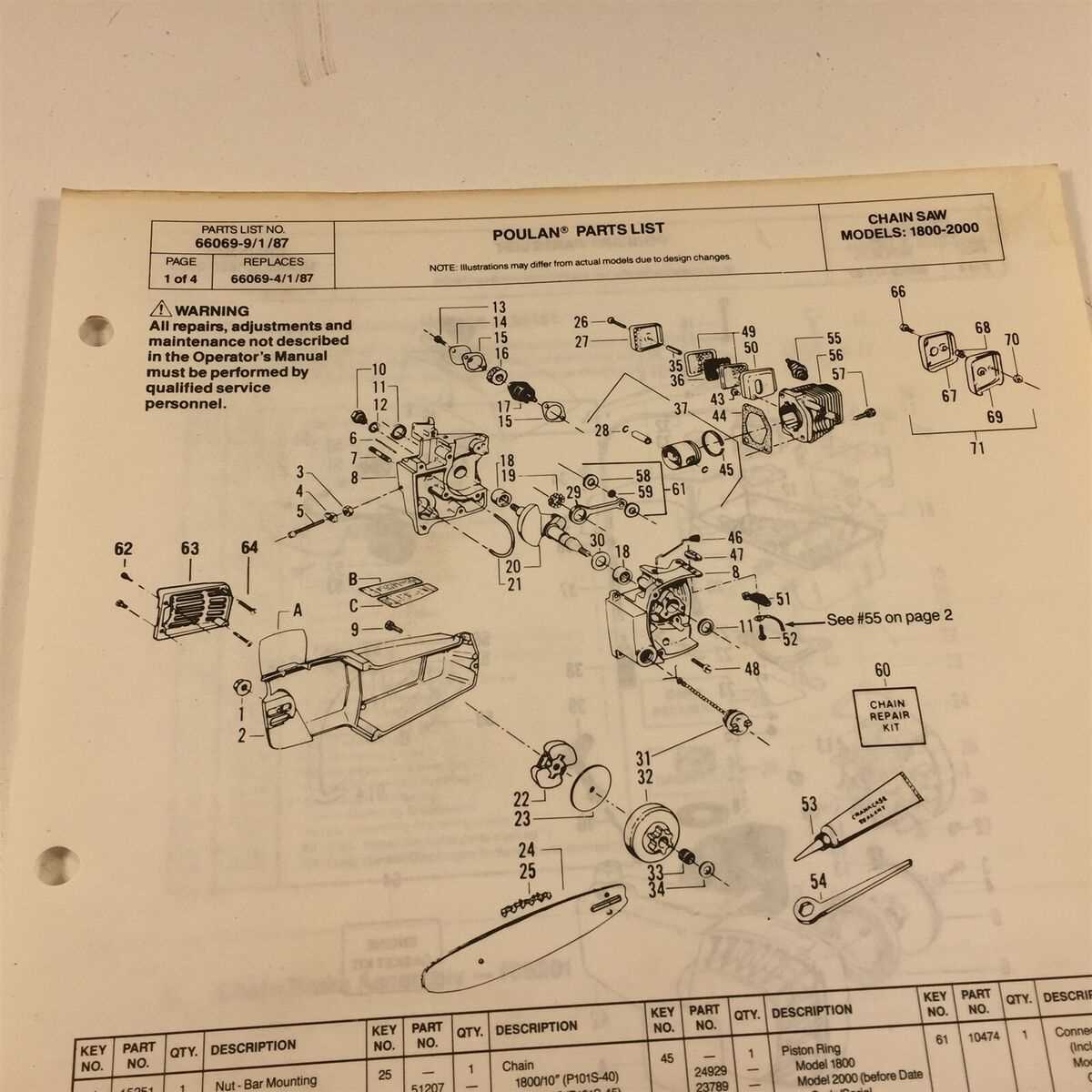

For those unfamiliar with the technical aspects, having access to visual references is invaluable. Diagrams that illustrate the parts and their connections simplify the repair process, making it easier to pinpoint where issues lie. These tools provide clarity, allowing users to confidently navigate the maintenance process and restore their equipment to full functionality.

Understanding the Equipment Breakdown

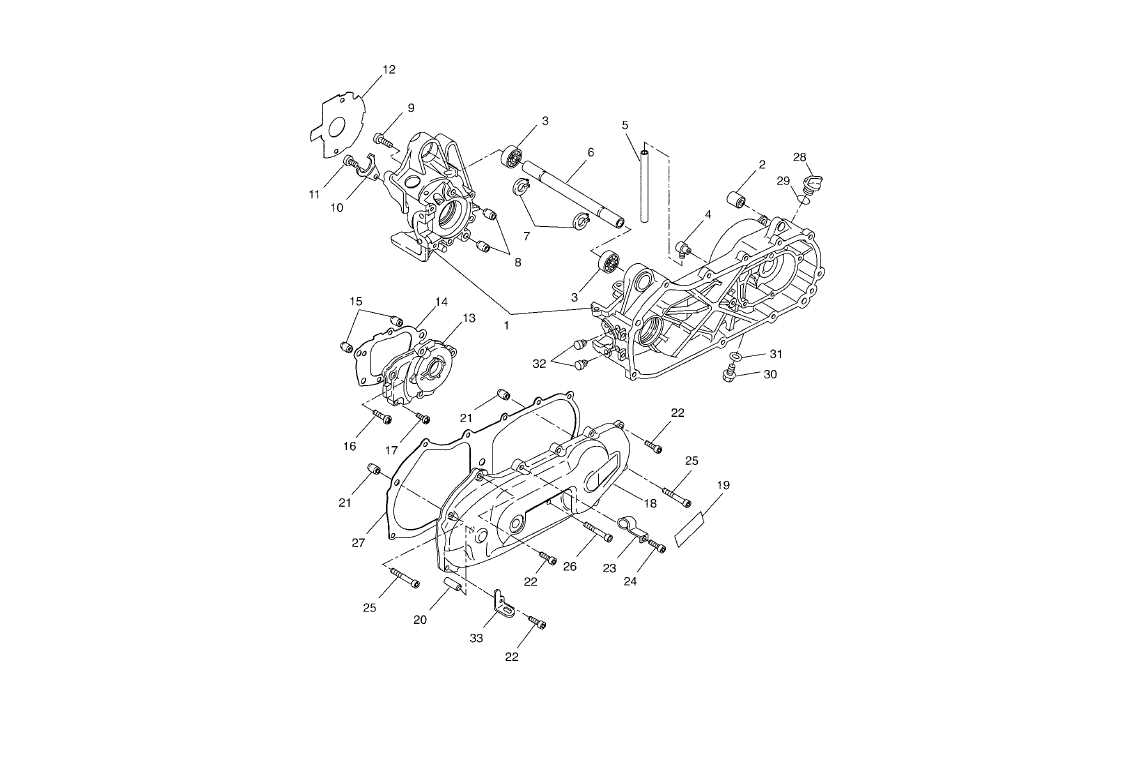

Proper maintenance begins with understanding the internal structure of your machinery. A well-organized visual representation of its components allows you to identify each element and how they function together. This clarity aids in troubleshooting issues and performing effective repairs, ensuring that your equipment stays in optimal condition.

Importance of Component Layout

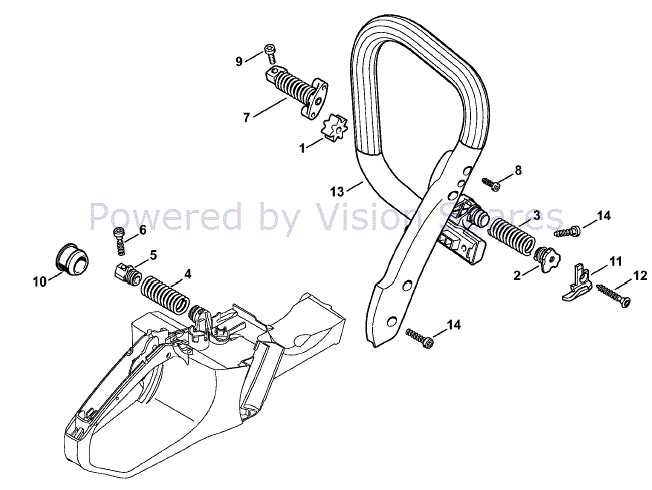

Each part in the assembly has a specific role, and understanding their positions within the system helps users comprehend how they interact. By carefully reviewing the layout, you can quickly spot worn-out or malfunctioning pieces, streamlining the repair process. This knowledge empowers you to make informed decisions about which components need attention and when.

How to Read and Use the Breakdown Effectively

When using a detailed reference guide, it’s important to familiarize yourself with its conventions. Understanding the way parts are labeled and connected visually ensures that you don’t miss crucial details during maintenance. By following the instructions and utilizing these references, you can confidently address any issues, from minor adjustments to major repairs.

Key Components of the Equipment Model

Understanding the main elements of your machinery is crucial for proper maintenance and repair. Each key component plays a significant role in the overall performance and efficiency of the device. Familiarity with these parts ensures that you can identify potential issues before they become major problems, allowing for quicker fixes and prolonged equipment life.

Engine and Power System is the heart of any outdoor machine. The power unit drives the rest of the system, providing the energy needed for operation. Recognizing the engine’s critical parts and how they interact with other systems is essential for diagnosing performance issues such as reduced power or irregular operation.

Transmission and Drive Mechanism transfers the engine’s power to the working components. This system ensures that motion is delivered accurately to the wheels or working parts, allowing the equipment to function as intended. Problems with the transmission often manifest as slipping, jerking, or inconsistent movement.

Control System includes various levers, switches, and sensors that regulate the machine’s operation. These elements must be well-maintained to ensure responsive handling and safe usage. A malfunctioning control system can result in poor performance or even accidents, making it essential to keep these components in good condition.

How to Use the Breakdown for Repairs

When it comes to fixing any malfunction in your equipment, having a clear visual reference is crucial. A well-organized breakdown helps you identify individual components and their connections, making it easier to locate and resolve issues. With the right guide, you can accurately pinpoint faulty parts and replace or repair them without confusion.

Step-by-Step Approach to Repairing

Start by locating the part that is malfunctioning on the breakdown. Carefully compare the diagram to the actual equipment to ensure you understand the positioning of each element. Once you’ve identified the problematic component, follow the step-by-step instructions to remove or replace it. This process minimizes the risk of damaging surrounding parts and ensures that repairs are made effectively.

Double-Check Before Reassembly

Before putting everything back together, it’s essential to double-check that the parts are correctly positioned and that the repair is complete. Verify all connections, ensuring that each component fits properly in place. This final check will prevent issues from arising after reassembly, ensuring that your equipment runs smoothly once again.