Maintaining and repairing outdoor tools can be a daunting task without the right knowledge. Understanding the various components that make up a machine is crucial for proper upkeep and effective troubleshooting. Having access to a clear visual guide can significantly simplify the process, providing you with the necessary insights to address any mechanical concerns.

Detailed schematics play an essential role in helping users identify parts and understand how they function together. By becoming familiar with these illustrations, you’ll be able to spot potential issues quickly and know exactly what needs attention or replacement.

Proper knowledge of each section ensures that you’re prepared for DIY repairs or servicing. Whether you’re a novice or an experienced technician, understanding how each element fits into the larger system is key to keeping your tools running smoothly for years to come.

Understanding Outdoor Tool Components

When it comes to maintaining a powerful outdoor device, recognizing the individual components is essential for effective troubleshooting and repair. Each section plays a specific role in the overall operation, and understanding how these parts interact can help users pinpoint malfunctions quickly. Having a clear grasp of each element ensures that you’re prepared for any necessary maintenance, whether it’s a minor fix or a more complex replacement.

Key Elements of the Equipment

Every device consists of a variety of mechanical pieces, each with its own purpose. The motor, air intake system, and exhaust are just a few of the core components that enable efficient functioning. Additionally, elements such as the housing and control switches help guide and manage the machine’s performance. A comprehensive understanding of these main sections provides the foundation for identifying problems and carrying out repairs with confidence.

Common Parts and Their Functions

Among the various sections, several parts stand out for their crucial roles. The motor generates the necessary power, while the fan and nozzle direct airflow to perform specific tasks. Components like the fuel system and ignition system work together to ensure smooth operation, while protective covers shield the internal machinery from debris and damage. Understanding these essential parts makes it easier to recognize signs of wear and tear, ensuring that the tool continues to perform at its best.

How to Read a Parts Illustration

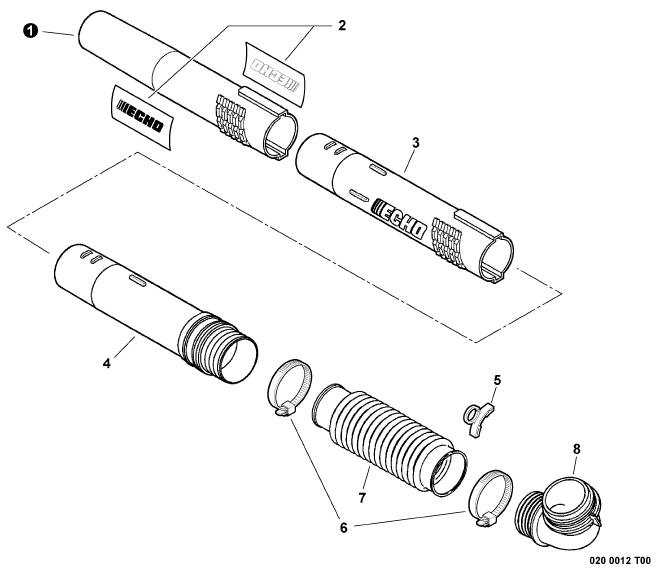

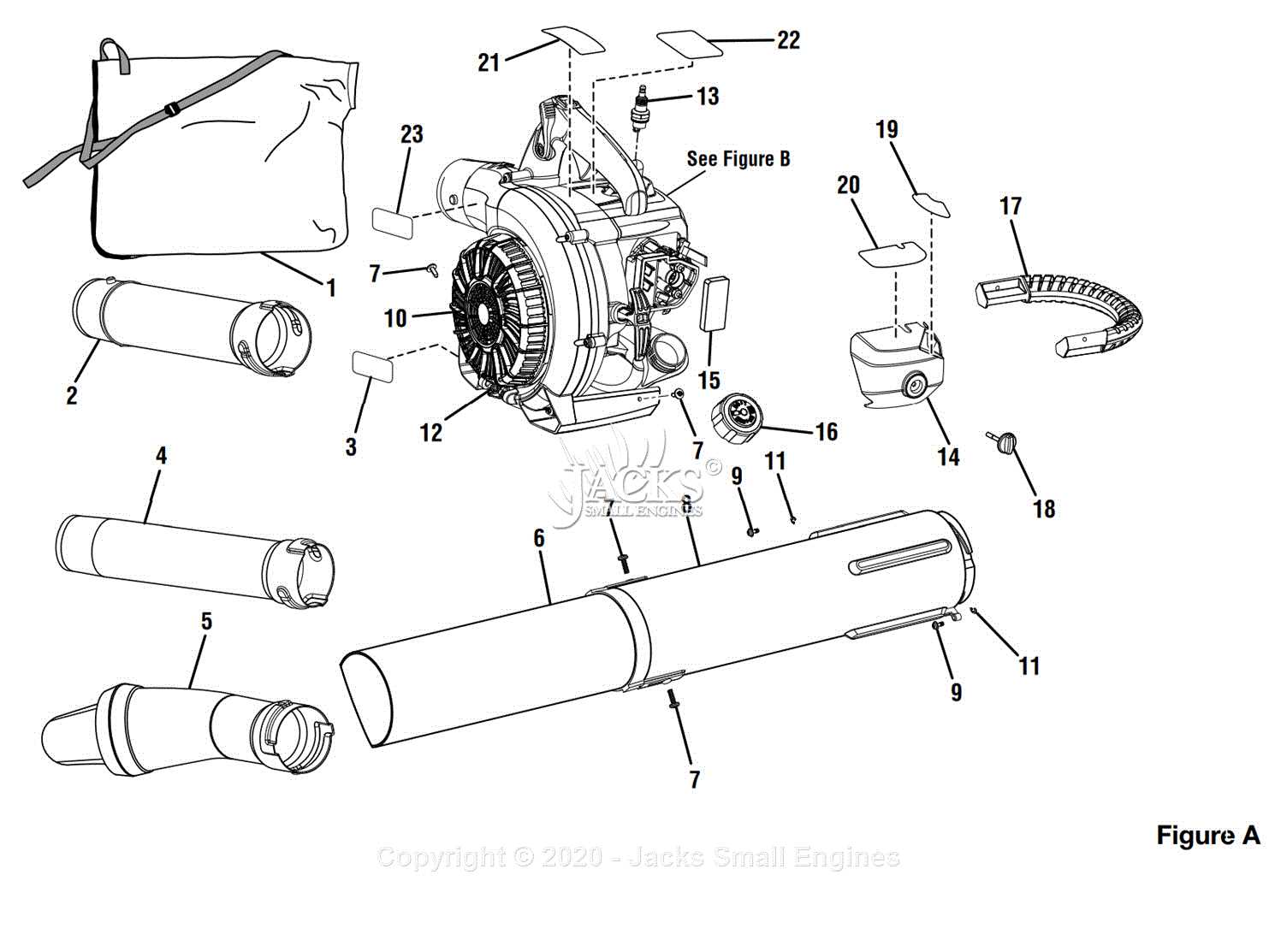

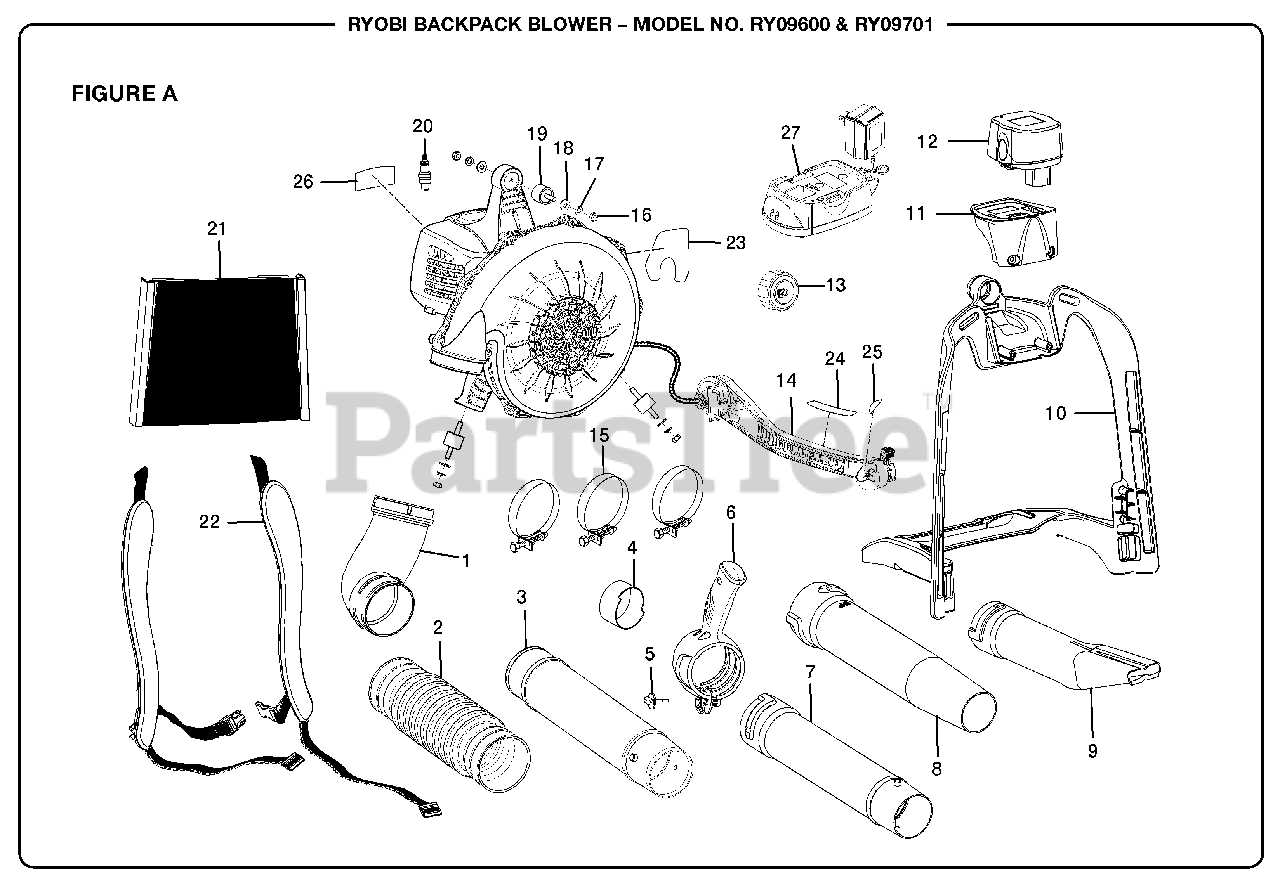

Interpreting an assembly diagram is an essential skill for anyone involved in repairing or maintaining outdoor equipment. These visual guides provide a clear breakdown of each individual component, offering detailed views of how parts fit together and their functions. Understanding how to read these illustrations allows users to quickly locate issues and identify the parts that need attention.

Identifying Components

Each part is labeled in the illustration with unique identifiers, such as numbers or letters, which correspond to a parts list. This list typically offers descriptions and additional details, including part numbers, sizes, and materials. Familiarity with the symbols and labels used in the diagram ensures that you can easily match each component to its counterpart, helping you avoid confusion during repairs.

Understanding Assembly and Disassembly

Many diagrams also show how parts are assembled and disassembled, providing clear indications of the order in which the components should be handled. This is particularly useful when dealing with complex machines that require precise steps for reassembly. By following the guide, you can avoid common mistakes and reassemble the tool correctly after replacing a part or performing maintenance.

Common Issues with Outdoor Equipment Components

Even the most reliable outdoor devices can experience issues over time. Understanding the most frequent problems associated with individual components helps in diagnosing malfunctions and addressing them efficiently. From wear and tear to improper assembly, several factors can affect the performance of your tool, making it essential to identify these common challenges early on.

Clogging and Blockages

One of the most frequent issues with outdoor machines is clogging, often caused by dirt, debris, or dust buildup. This can lead to reduced airflow and efficiency, making the device less effective. Regular cleaning of air intake and exhaust systems is necessary to avoid blockages and ensure the smooth operation of the machine.

Wear and Tear on Moving Parts

Over time, components such as motors, fans, and nozzles can show signs of wear. This could result in decreased performance or even complete failure. Checking for signs of damage or unusual noise is important in identifying these issues early, allowing for timely repairs or replacements to avoid a more costly breakdown.