When working with small power equipment, it’s essential to have a clear understanding of its internal mechanisms. A thorough breakdown of the system’s individual elements allows for better maintenance and smoother repairs. Whether you’re a seasoned mechanic or a beginner, knowing how each part functions can prevent costly mistakes and ensure the longevity of the machinery.

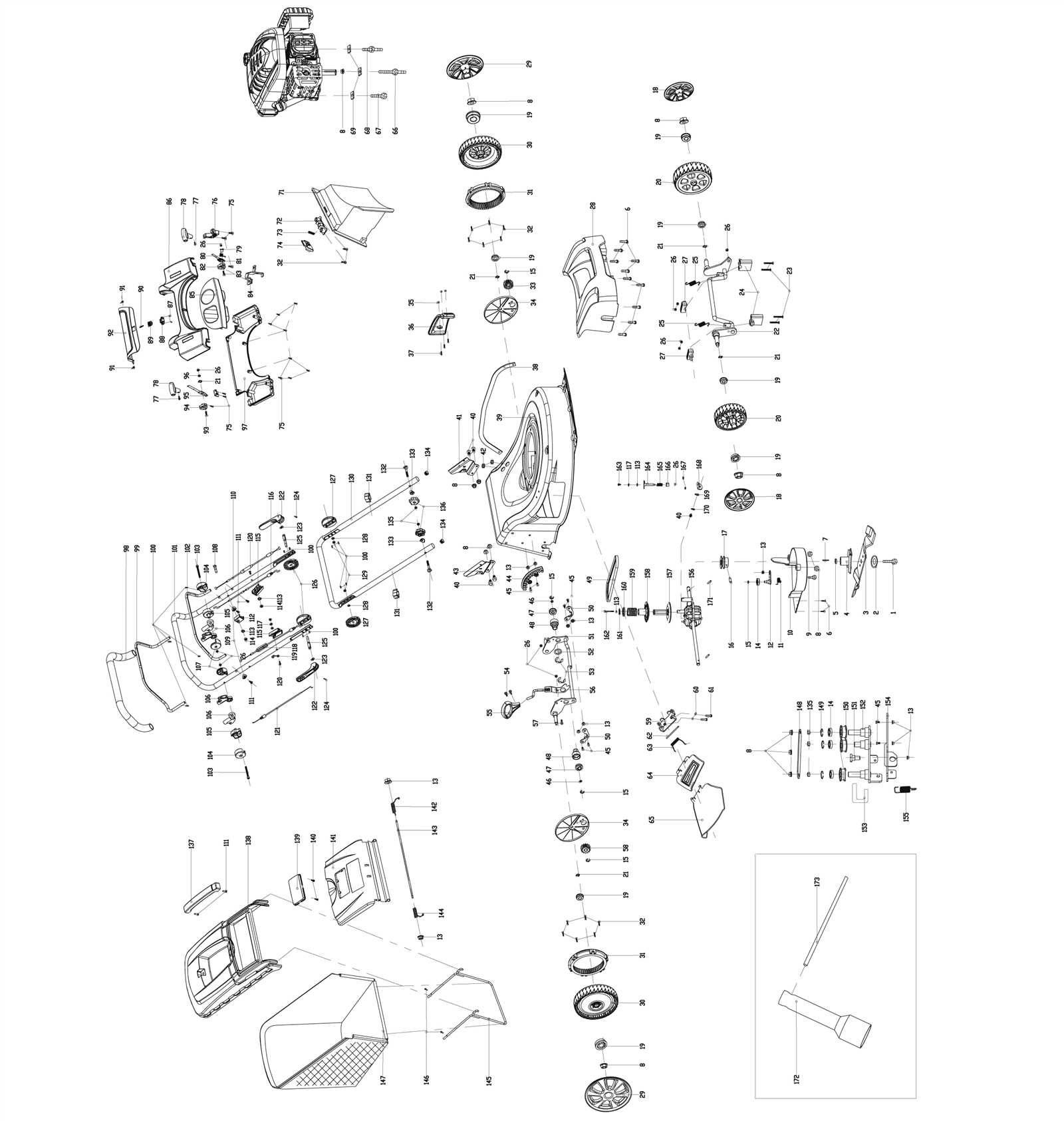

Having a visual guide that highlights the various components can significantly improve your ability to identify and troubleshoot issues quickly. By referencing such guides, you can easily pinpoint the source of malfunctions, reduce downtime, and make informed decisions on replacements or adjustments. With this knowledge, maintaining and servicing your equipment becomes a much simpler and more efficient task.

Understanding the Small Power Unit

A small power unit is designed to provide reliable performance in various outdoor and industrial applications. The heart of these systems lies in the intricate balance of moving components, each serving a specific purpose to generate and harness power efficiently. Familiarity with the structure and function of each individual element is crucial for anyone looking to maintain or repair such machinery.

The design of these units often incorporates a combination of mechanical and electrical systems, all working in harmony to produce consistent output. Each component, from the intake system to the ignition, plays a role in ensuring smooth operation. Understanding the relationship between these parts helps users troubleshoot issues and perform repairs with greater confidence and accuracy.

Key Components of the Power System

The efficiency of any small power system relies on the coordinated functioning of its core elements. Each component plays a vital role in ensuring that the entire machine operates smoothly and reliably. From controlling airflow to regulating fuel delivery, these parts work together to create optimal performance, making regular inspection and maintenance essential for long-term use.

Air Intake and Fuel Delivery

The air intake system allows the right amount of air to enter the combustion chamber, while the fuel delivery mechanism ensures a consistent supply of fuel. Together, they facilitate the proper air-fuel mixture needed for ignition. Any disruption in these systems can lead to poor performance, making their proper functioning a top priority for maintenance.

Ignition and Compression Systems

The ignition system generates the spark needed to ignite the fuel-air mixture, while the compression system ensures that the mixture is pressurized to the correct level for efficient combustion. These two systems are essential for the power unit’s ability to start reliably and run smoothly, requiring close attention to avoid potential failures.

How to Use the Parts Diagram Effectively

A visual reference guide is an invaluable tool when it comes to understanding and servicing mechanical systems. It allows users to identify individual components quickly, making maintenance and repairs more efficient. By referring to these detailed illustrations, you can pinpoint issues, verify part placement, and even order the correct replacements with confidence.

Identifying Components and Functions

The first step in using a schematic effectively is to familiarize yourself with each part’s function. A well-labeled illustration typically highlights each component and its relation to the overall system. By learning the role of each element, you’ll be able to recognize how they work together and spot any potential problems that may arise during operation.

Guiding Maintenance and Repairs

When performing repairs or regular upkeep, the diagram serves as a roadmap to ensure you’re working on the right components. This guide will help you assess whether the components are installed correctly, check for signs of wear, and troubleshoot any malfunctions. With a clear visual representation, diagnosing issues becomes a much smoother process.