Understanding the key components of your lawn tractor’s control system is essential for maintaining its performance and ensuring smooth operation. The control mechanism plays a crucial role in maneuvering the machine efficiently, which makes knowing how to identify, replace, and troubleshoot these elements invaluable for any operator.

Whether you’re dealing with a malfunction or looking to upgrade specific features, recognizing the various components that contribute to the overall functionality can help you resolve issues quickly. This guide will provide insights into how these parts interact, what common problems to expect, and the steps required to address them.

Proper maintenance and timely repairs not only prolong the lifespan of your equipment but also enhance its effectiveness. By familiarizing yourself with the system’s layout, you’ll be better prepared to handle any challenges that may arise.

Understanding the Control System Components

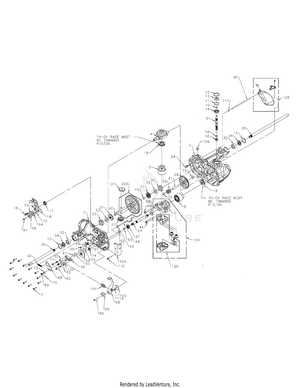

The control mechanism of a lawn tractor consists of several critical elements that work together to allow precise handling and movement. These components ensure that the operator can guide the machine smoothly across different terrains and handle any tasks with ease. Recognizing the role each part plays can help in diagnosing issues and performing maintenance effectively.

Key Elements of the Control Mechanism

At the heart of the system is the pivot assembly, which connects various mechanical elements and ensures the vehicle responds accurately to directional inputs. This is often linked with the linkages and various gearing components that transmit force from the operator’s controls to the wheels. Properly functioning linkages are vital for responsive operation.

Maintenance and Inspection Tips

Regular inspection of these components is essential to avoid malfunctions that could hinder the vehicle’s movement. Pay special attention to the joints and connectors that may wear over time. A simple visual check can reveal potential issues, and addressing them early can prevent more extensive damage.

Common Issues with Control Mechanism

Over time, various issues can arise with the system that controls the movement of the machine, often resulting in reduced responsiveness or difficulty in maneuvering. These problems are typically linked to wear and tear on key components, misalignment, or lack of maintenance. Identifying and addressing these issues early can save both time and money in the long run.

One common problem is loose or damaged linkages, which can lead to inconsistent control. If the mechanism does not respond promptly, it may be due to worn-out connectors or improper adjustments. Another frequent issue is misalignment of the wheels, which can make turning difficult or cause uneven tire wear. Regular checks of these parts can prevent such issues from escalating.

How to Replace Steering Components Efficiently

Replacing components of the control system requires careful attention to detail to ensure smooth operation after the repair. Following the proper procedure will minimize downtime and help restore functionality without causing additional damage. Understanding the essential tools and steps involved is key to completing the task efficiently.

Step-by-Step Process for Replacement

The first step is to identify the faulty component, whether it’s a worn linkage or a damaged connector. Begin by carefully lifting the front section of the machine and securing it. Next, use the appropriate tools to remove the old component, taking care not to damage surrounding parts. Once removed, replace it with the new part, ensuring it is aligned correctly and securely fastened.

Post-Replacement Tips

After installation, test the new component by manually moving the control mechanism to ensure it moves smoothly. Perform a few test runs to check for responsiveness. If necessary, make adjustments to align the system properly. Regular maintenance after replacement is essential to prolong the lifespan of the newly installed parts.