When maintaining or repairing a power tool, understanding the structure and function of its individual elements is crucial. Proper knowledge allows for efficient troubleshooting and ensures that each part performs its intended task. This section will guide you through identifying key components and their roles, helping you keep your equipment in top working condition.

Whether you’re replacing a worn-out component or performing routine upkeep, familiarizing yourself with the internal structure can make the process much easier. Each piece of machinery is designed with a specific purpose in mind, and understanding how they interact is essential for optimal performance.

Detailed visuals and descriptions will assist you in recognizing the various sections and mechanical parts, enabling a smoother repair or maintenance experience. Knowing where each component fits within the larger system can prevent common mistakes and reduce the risk of damage during the process.

Understanding Poulan Chainsaw Components

When working with a power tool, it’s important to have a clear understanding of its individual components and how they contribute to overall performance. Each element, no matter how small, plays a specific role in the machine’s efficiency and durability. A deep knowledge of these elements allows for better troubleshooting, quicker repairs, and a longer lifespan for the equipment.

Key Components and Their Functions

Every tool consists of several key components that perform essential functions. From the motor to the cutting mechanism, understanding each part’s purpose ensures proper operation. For instance, the engine provides the power needed to drive the cutting chain, while the drive mechanism transfers this power efficiently. Similarly, the safety mechanisms protect the user, preventing accidents while using the machine.

How Parts Interact Within the System

Each component is interconnected, and their performance depends on how well they work together. A malfunction in one part can cause issues throughout the system. Regular maintenance, such as cleaning and lubricating moving parts, is essential to keep the tool running smoothly. Identifying which part is underperforming can significantly reduce downtime and extend the life of your equipment.

How to Read Poulan Chainsaw Diagrams

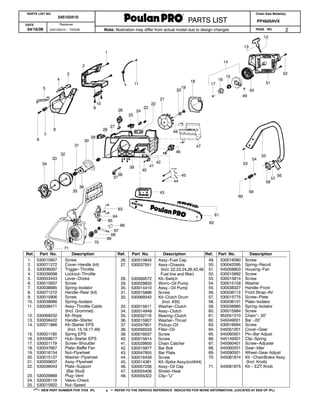

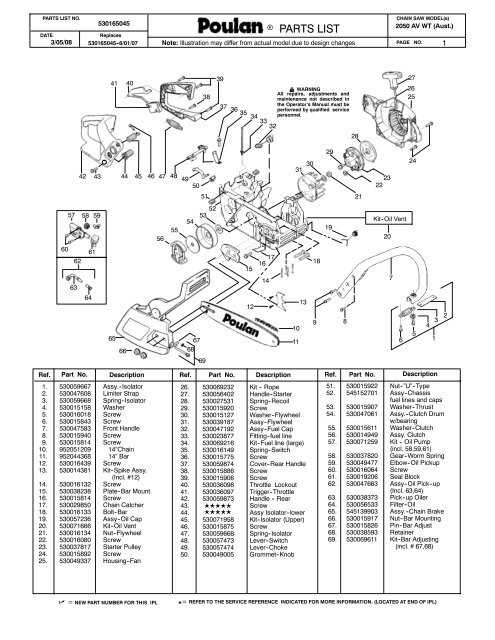

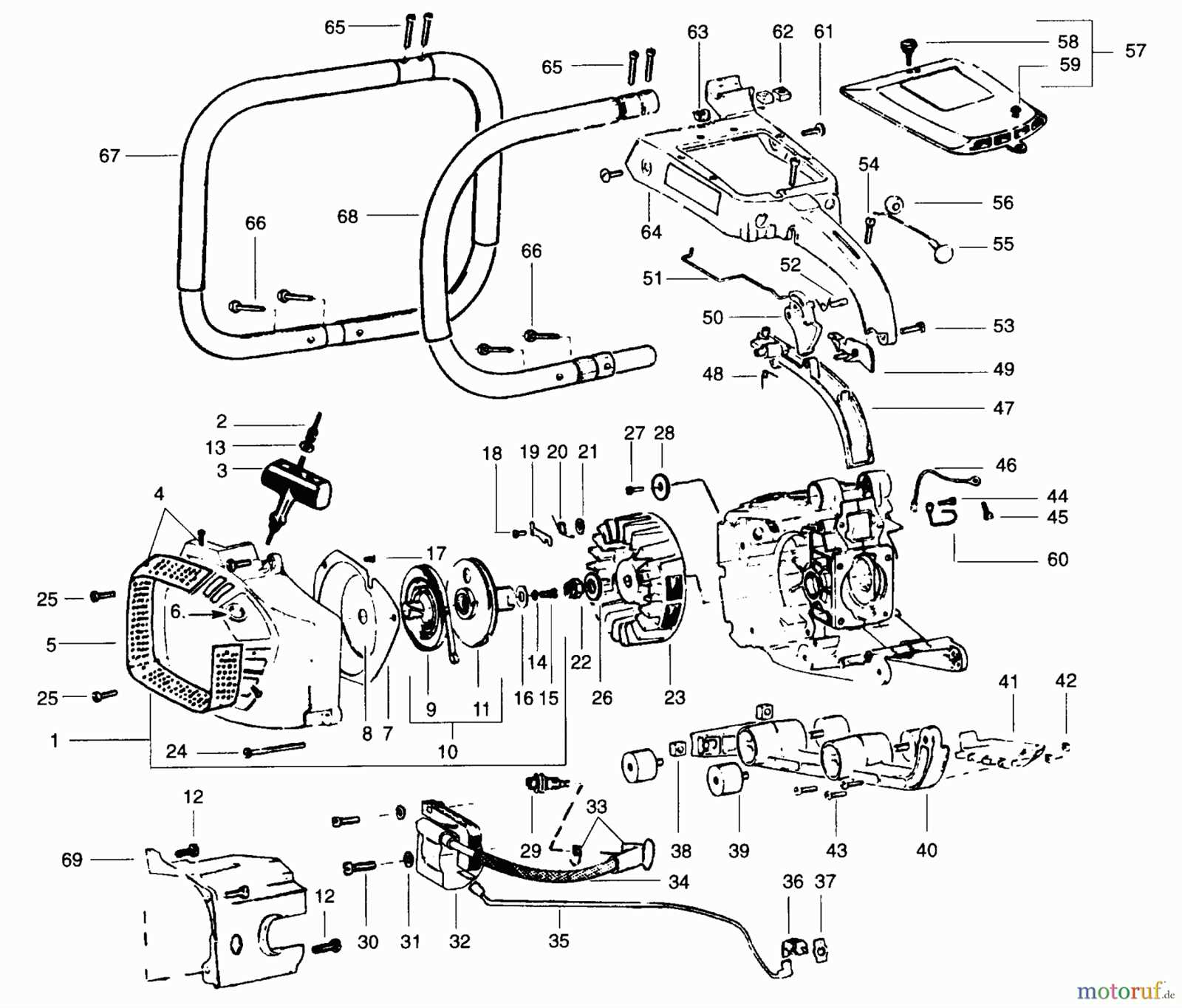

Understanding technical schematics is crucial when it comes to repairing or maintaining power equipment. These illustrations provide detailed visual representations of the internal structure, making it easier to identify components and their placement within the system. Knowing how to interpret these diagrams simplifies the process of assembly, disassembly, and replacement of parts.

First, familiarize yourself with the symbols and labels used in the schematic. Each part is usually marked with a specific number or letter, and these identifiers correspond to a list or legend that provides further information. Pay attention to the lines connecting various components; they indicate how parts are linked or interact with each other within the system.

Also, note the scale of the diagram, as some details may appear more simplified than others. Focus on the primary components first and then proceed to smaller, more intricate sections. By working through the diagram step by step, you can gain a clearer understanding of how each element fits into the larger mechanism.

Common Parts and Their Functions

Power tools consist of a variety of components, each designed to perform a specific function. These elements work in unison to ensure smooth operation and optimal performance. Understanding the role of each part is essential for proper maintenance and repair, helping users address issues quickly and accurately.

One of the most important components is the engine, which provides the power needed for the entire system to function. The fuel tank supplies the necessary energy, while the ignition system ensures that the engine starts and runs smoothly. Another key part is the drive mechanism, which transfers energy from the engine to the cutting tool, allowing for efficient operation. The cutting elements themselves are designed for precision, and their condition directly impacts the tool’s performance.

Safety features are also integral to the system, such as the brake mechanism that prevents accidents and the vibration dampening system that reduces strain on the user. Regularly checking these components ensures the tool remains safe and effective to use. Additionally, the air filter, spark plug, and lubrication system are essential for keeping the engine running efficiently over time.