Maintaining your outdoor equipment can seem like a daunting task, but understanding its internal structure can make repairs and maintenance easier. Each model has unique elements that contribute to its overall functionality, from cutting mechanisms to safety features. Familiarizing yourself with these components allows for better care and efficient troubleshooting.

Identifying the right components is crucial when attempting to fix or upgrade your equipment. Knowing where each piece fits in the assembly can save time and prevent unnecessary damage. Clear identification helps you address issues without confusion, ensuring that everything functions smoothly for longer periods of time.

Once you know what to look for, problems can be resolved quickly, whether they involve wear and tear or performance decline. With the right approach, you can keep your tools running at peak efficiency, making lawn care a much simpler and more enjoyable task.

Understanding Lawn Care Tool Components

Proper knowledge of how a lawn care device is constructed is essential for efficient usage and repair. By breaking down each component, you can better understand their roles and how they work together to ensure optimal performance. From the engine to the cutting system, each part plays a crucial role in the overall functionality of the tool.

Key Elements of the Machine

The engine serves as the heart of the device, powering the various functions that make lawn maintenance possible. Its efficiency directly affects the overall performance. Other essential components, like the blade assembly, control how precisely the machine cuts, while safety features ensure safe operation. Understanding how these parts interact helps identify potential issues early.

Common Wear and Tear

Even with proper maintenance, certain components will wear out over time due to regular use. Blades can become dull, and the motor may lose efficiency, especially after prolonged use. Regular inspection of these parts is vital to avoid unexpected breakdowns. Keeping an eye on these areas and replacing worn-out elements can significantly extend the lifespan of your equipment.

How to Use the Parts Diagram Effectively

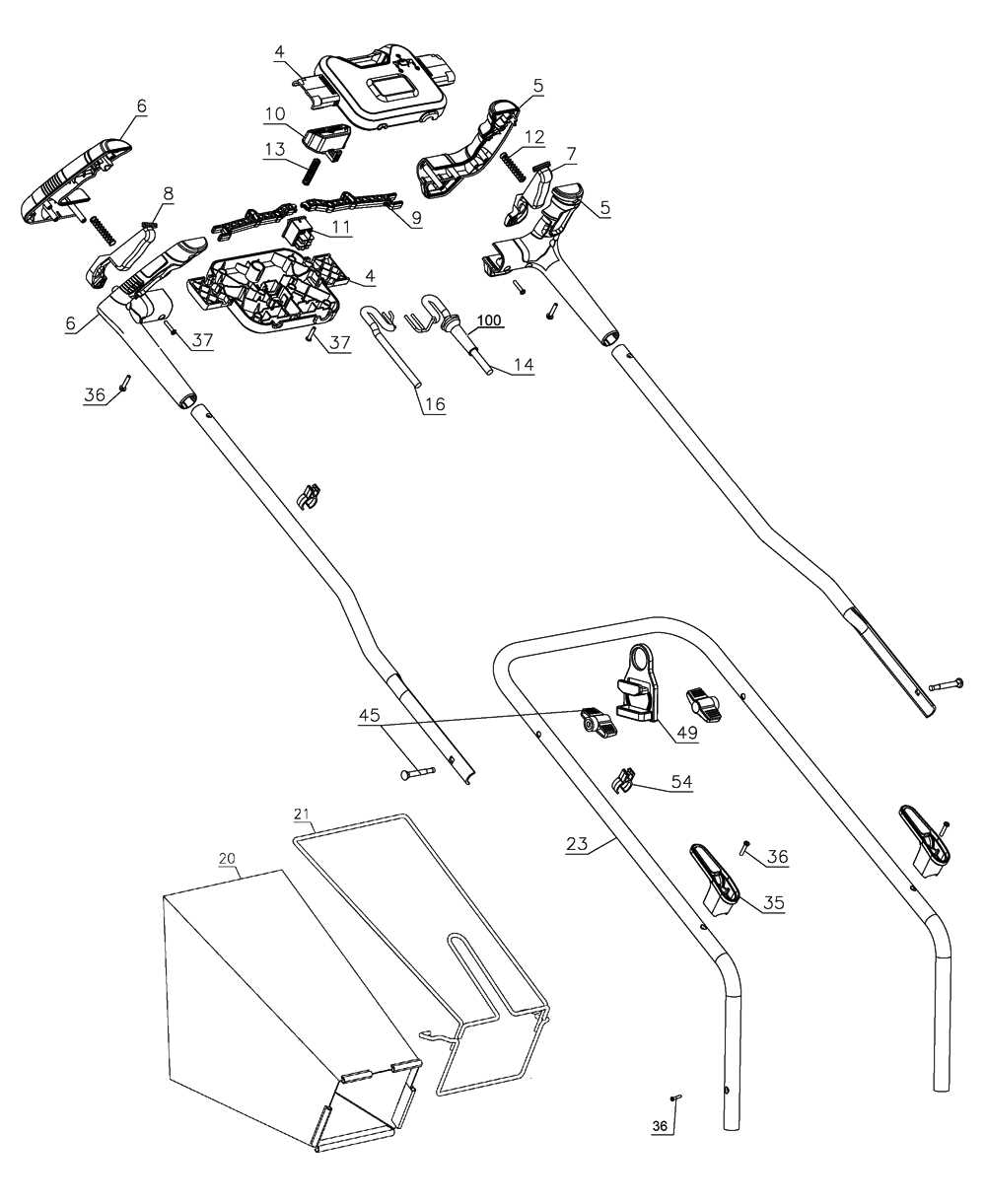

Understanding the structure of your lawn care tool is essential for efficient maintenance. A well-structured visual guide can simplify the process by clearly showing how different components fit together. By referring to these guides, you can quickly locate and identify parts that need repair or replacement, saving time and effort.

Locating the Necessary Components

Before you start any repair or upgrade, take time to familiarize yourself with the layout provided in the guide. Identify key sections first, such as the cutting mechanism and motor housing. Knowing where each part is located allows for quicker access during maintenance, reducing the risk of unnecessary disassembly.

Understanding the Relationships Between Parts

The diagram also illustrates how various elements interact. For example, the drive system connects to the motor, while the cutting blades are controlled by a set of pulleys. Understanding these relationships ensures that you’re not just replacing parts, but addressing the root cause of any issues, leading to more effective repairs.

Common Issues and Fixes for Mower Parts

Even with regular care, tools designed for lawn maintenance can develop issues over time. Understanding the most common problems can help you quickly identify when something is wrong and take the necessary steps to fix it. Addressing these issues promptly prevents further damage and ensures the continued performance of the machine.

Blades Dullness and Inefficiency

One of the most frequent issues with cutting equipment is dull or damaged blades. Over time, blades can lose their sharpness due to contact with hard objects or general wear. Replacing or sharpening the blades will restore cutting efficiency and ensure clean results. Always check the condition of the blades regularly to avoid further complications.

Motor Overheating

If the motor begins to overheat, it may be due to debris accumulation or internal damage. Cleaning the motor housing and checking for blockages is a simple first step in addressing this problem. If the issue persists, the motor may need to be inspected or replaced. Regular cleaning and maintenance can prevent overheating and extend the life of the motor.