Heavy machinery relies on a wide array of interdependent components that work seamlessly to perform complex tasks. Each element plays a crucial role in ensuring the smooth operation of the entire system, enabling machines to handle demanding projects with precision and efficiency.

In order to fully grasp the mechanics behind these machines, it is essential to explore the structure and function of key components. By understanding how each part contributes to the overall performance, operators and technicians can make informed decisions about maintenance and troubleshooting.

Effective management of these systems can lead to enhanced productivity and prolonged lifespan, making knowledge of their inner workings indispensable for anyone involved in heavy equipment operation or repair.

Understanding Heavy Machinery Components

The efficiency of large-scale construction equipment depends on the seamless interaction between its various elements. These machines rely on numerous integral systems working together to perform tasks like lifting, digging, and hauling. A deep understanding of each individual component is essential for optimal performance and longevity.

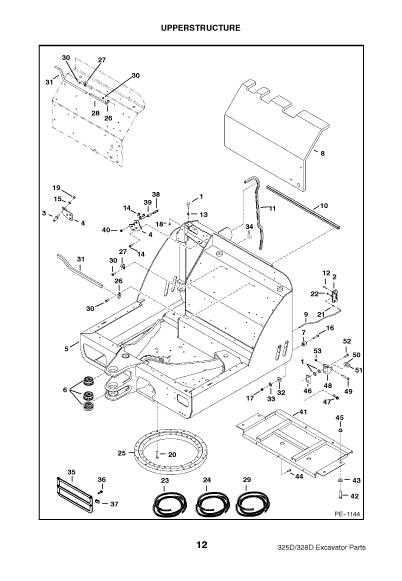

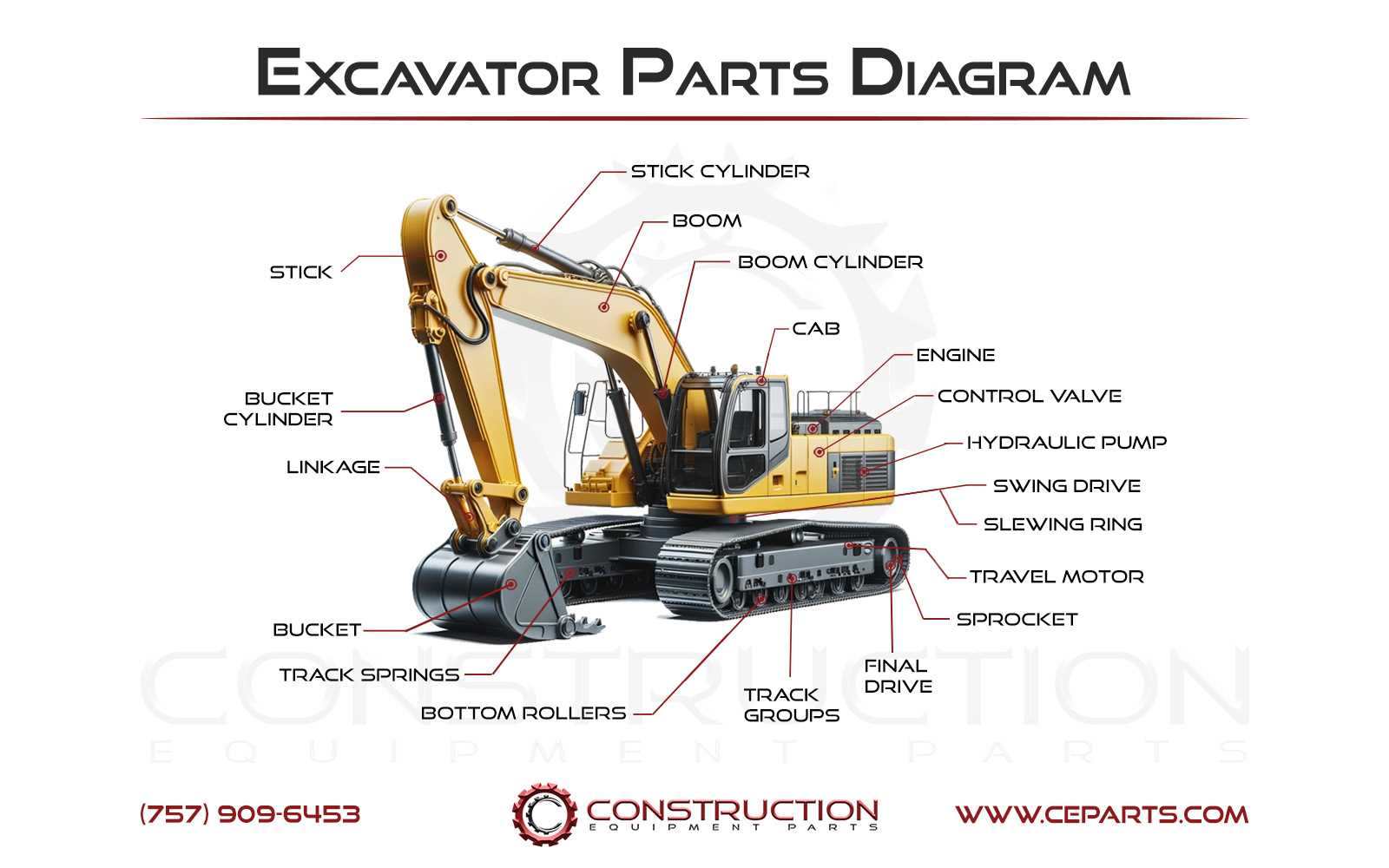

The machinery’s structure includes both mechanical and hydraulic systems that drive movement, power, and control. Each system is designed with specific functions, all contributing to the overall strength and precision of the machine. Recognizing how these components interact can help operators troubleshoot issues and ensure smooth operation during demanding tasks.

By examining each key system, from the engine to the tracks, maintenance and repairs can be better managed, preventing costly downtime. A comprehensive grasp of these mechanisms is vital for anyone working with such equipment, whether for routine inspection or more complex repairs.

Key Components and Their Functions

The efficiency of large construction equipment relies on the performance of several crucial systems. Each element has a specific function that supports the overall operation, enabling the machine to perform a wide range of tasks. Understanding these key systems is essential for ensuring smooth and safe operation in demanding environments.

For example, the engine serves as the powerhouse, providing the necessary energy to drive the machine. Hydraulic systems control the movement of the boom and arm, allowing for precise digging and lifting. The undercarriage, including tracks and wheels, ensures mobility across various terrains, while the operator’s cabin houses the controls for managing all operations with accuracy.

Every component is designed to contribute to the machine’s overall effectiveness, with redundancy built into critical systems to enhance reliability. Recognizing the roles and interdependencies of these systems allows for better maintenance and troubleshooting, minimizing downtime and extending the equipment’s lifespan.

How Heavy Machinery Systems Work Together

The effectiveness of heavy equipment hinges on the coordination of various systems. Each component, from power generation to movement, must work in unison to ensure the machine operates efficiently and performs complex tasks. These systems are interdependent, and any disruption in one can affect the entire operation.

For instance, the engine generates the power needed to drive the machine, while the hydraulic systems convert this power into the necessary force to move the arms or lift heavy loads. The undercarriage maintains stability and mobility, ensuring that the machine can navigate through different terrains without losing balance. The operator controls all these systems from a centralized control panel, making real-time adjustments to maximize performance.

| System | Function |

|---|---|

| Engine | Generates power for all operations |

| Hydraulics | Controls movement and force for lifting and digging |

| Undercarriage | Ensures stability and movement across terrain |

| Control Panel | Allows the operator to manage all systems and actions |

By understanding how each system contributes to the overall functionality, operators can better manage tasks and troubleshoot issues when they arise. This coordination ensures smooth operation and enhances the overall lifespan of the equipment.

Efficiency Through Integrated Components

The true strength of complex machinery lies in the seamless integration of its various systems. When each element works in harmony, the overall performance becomes significantly more efficient, reducing the likelihood of errors or inefficiencies. These interconnected systems ensure that energy is utilized optimally, leading to smoother operations and lower fuel consumption.

For example, when the hydraulic mechanisms, power generation, and mobility systems are finely tuned to work together, the machine can achieve higher precision and output without wasting resources. This integration minimizes unnecessary wear and tear on individual components, extending the lifespan of the equipment.

Moreover, having well-integrated systems allows operators to handle complex tasks with greater ease and confidence. By eliminating redundant processes, the machine can perform operations more quickly and effectively, providing a competitive edge in demanding environments.

Common Heavy Machinery Maintenance Tips

- Check hydraulic fluid levels regularly to prevent system failure.

- Inspect tracks and undercarriage for wear and tear, replacing components as needed.

- Ensure the cooling system is functioning properly to avoid overheating.

- Examine the engine for leaks, clean air filters, and replace fuel filters as required.

- Lubricate moving parts to reduce friction and prevent premature damage.

Following a regular maintenance schedule not only improves the performance of the machine but also helps in avoiding costly repairs. Keeping detailed records of inspections and repairs ensures the equipment runs smoothly throughout its lifespan.