Every complex machine relies on a series of interconnected elements that work together to ensure smooth and efficient operation. In the case of water circulation equipment, identifying each component and its role is crucial for proper maintenance and repair. Without a clear understanding, it can be difficult to pinpoint issues or perform necessary fixes when problems arise.

Having a visual representation of the system can significantly aid in recognizing each part’s function. This guide will explore how the different sections come together, ensuring that you can identify and address any potential issues with ease. Whether you’re troubleshooting or performing regular upkeep, understanding these components is key to maximizing the efficiency and lifespan of your system.

Overview of Pump System Components

In any water circulation setup, understanding the various elements that drive its functionality is crucial. These systems consist of several key components that each play a vital role in ensuring everything runs smoothly. A well-maintained setup depends on the efficient operation of these elements working together in harmony, with each piece contributing to overall performance.

Essential Elements of the System

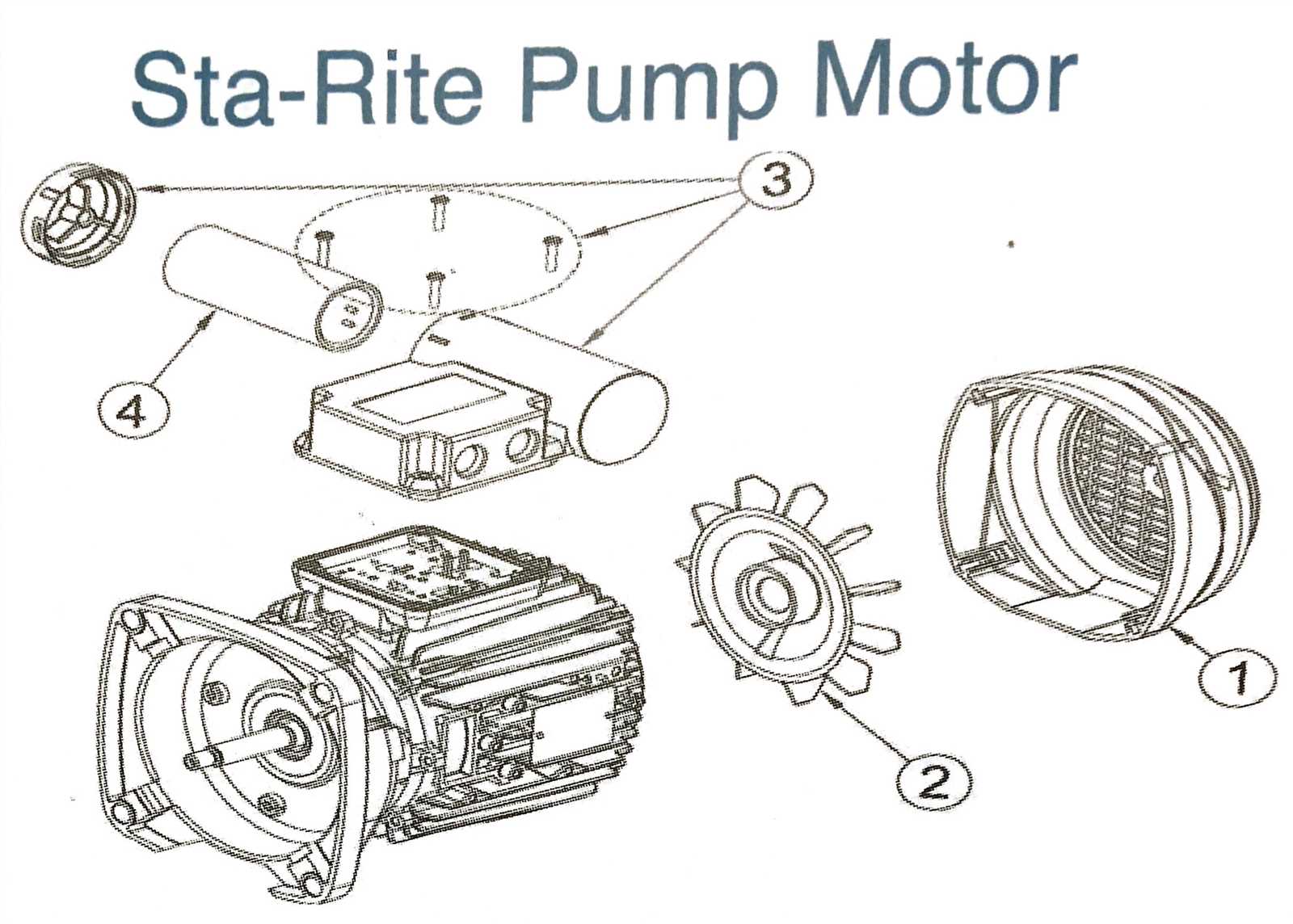

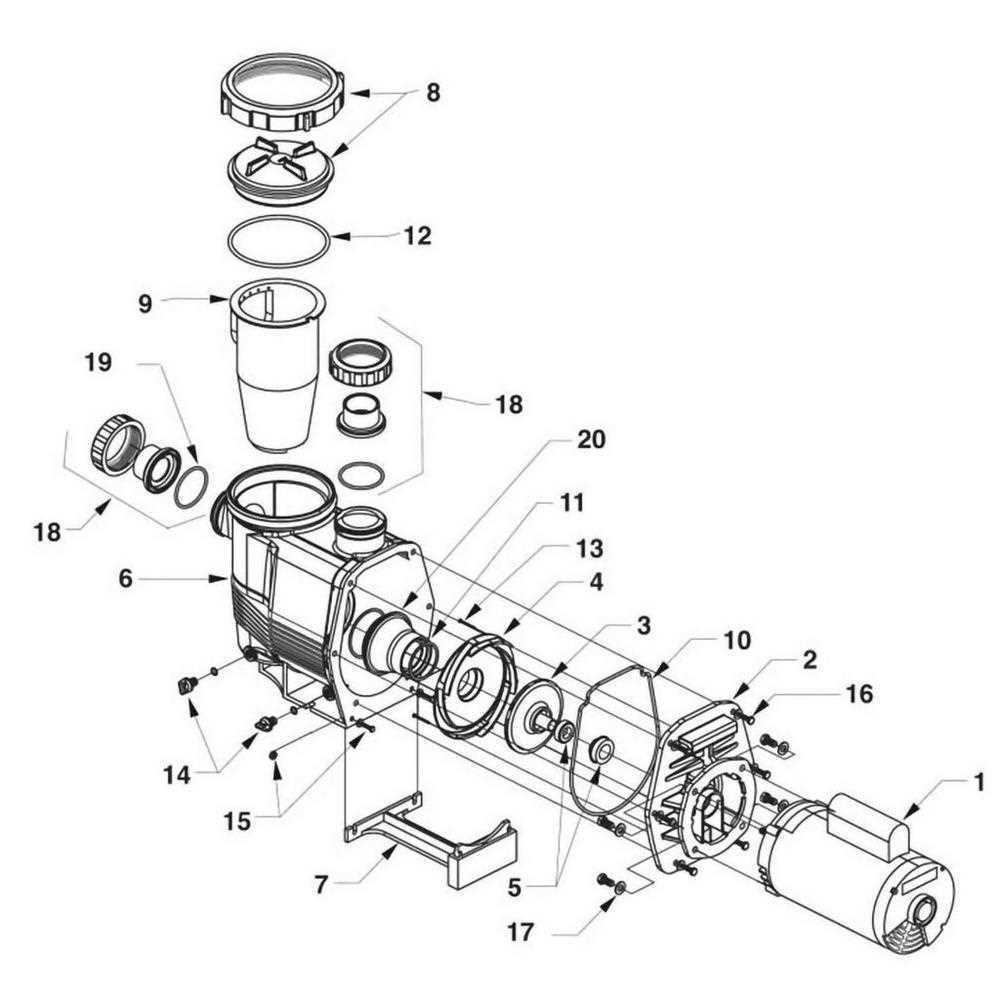

At the heart of the system are the components responsible for converting electrical energy into mechanical movement, enabling the entire setup to function as intended. These parts include electrical connections, the rotor, and housing, which protect and facilitate the movement of energy throughout the mechanism. Each of these elements requires careful attention during maintenance to ensure optimal performance and to avoid any unnecessary wear and tear.

Supporting Components and Their Roles

In addition to the main functional elements, there are supporting components that help regulate and protect the system. These parts include filters, seals, and other structural elements that help control flow, minimize energy loss, and ensure long-term reliability. Regular inspection and maintenance of these supporting components help avoid malfunction and extend the lifespan of the entire assembly.

Key Parts in Pump System Function

To ensure that a water circulation system operates efficiently, several core components are essential for its functionality. These elements work together to enable movement, control flow, and protect the internal structure. A breakdown of these key components helps in understanding how each one contributes to the overall performance of the system.

The driving force behind the setup is usually an electric component that generates mechanical power, enabling the movement of water. Connected to this is the housing, which serves as a protective shell for the internal workings, while the rotor or impeller transfers power and creates the necessary water flow. Additionally, seals and bearings play a crucial role in maintaining smooth operation by reducing friction and preventing leaks, ensuring that energy is efficiently transferred through the system.

How to Read a Pump System Blueprint

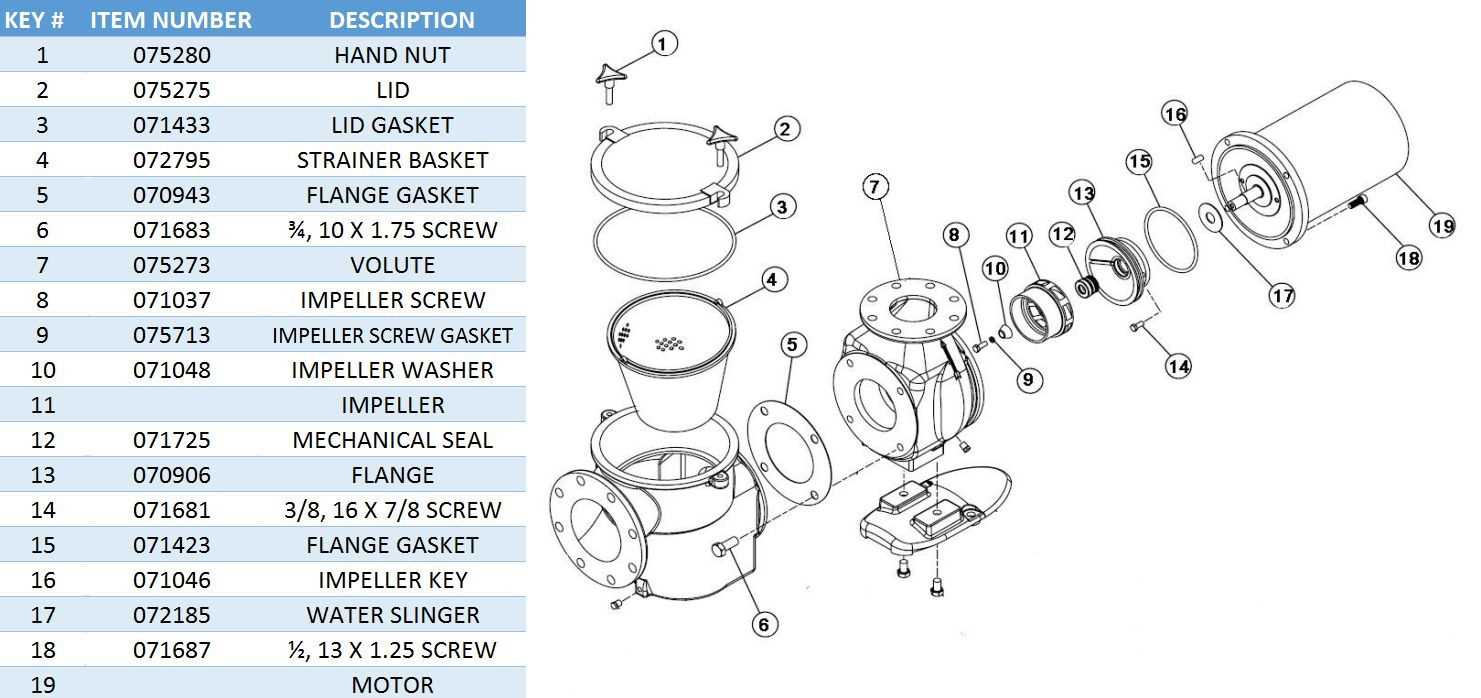

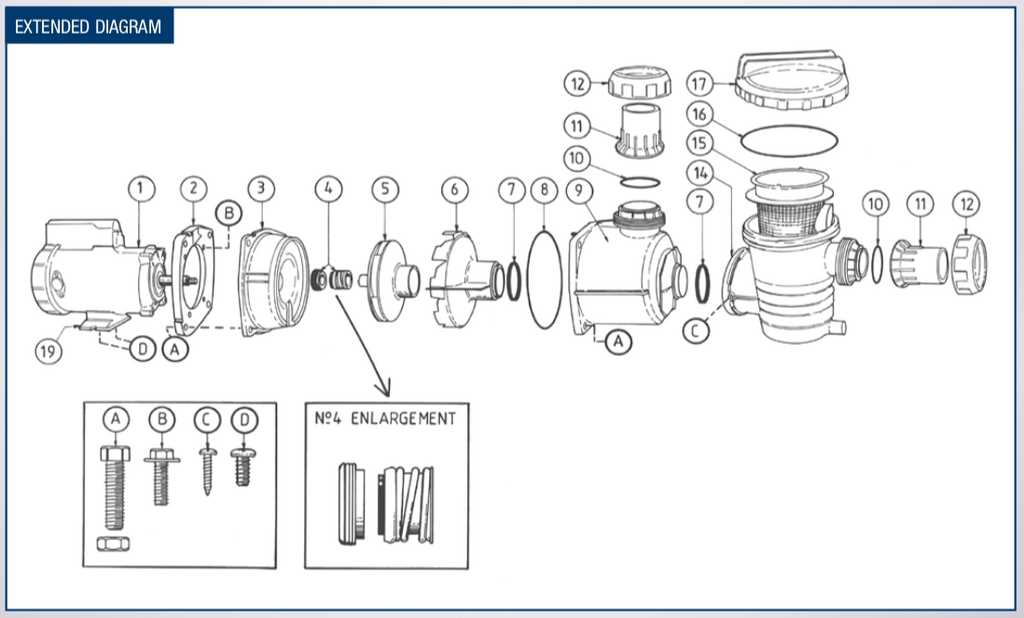

Understanding the layout of a water circulation setup can be daunting without the proper guide. A schematic serves as a visual map, illustrating how each component is connected and interacts within the system. By learning how to read these blueprints, you can quickly identify key elements, their functions, and potential problem areas.

To begin, start by recognizing the main components typically represented in the schematic. These are usually drawn with standardized symbols for easy identification. Lines indicate connections or flow paths, while labels describe the function or specifications of each element. Pay close attention to any directional arrows, as they indicate the flow of energy or water through the system. Understanding these symbols and their relationships will allow you to effectively navigate and troubleshoot the setup.