When it comes to maintaining heavy-duty equipment, having a clear understanding of its internal components is crucial. This guide offers an organized visual representation to help owners and technicians identify essential elements for servicing machinery. With accurate identification of each part, troubleshooting and repair become more efficient, reducing downtime and ensuring optimal performance.

Effective use of this detailed reference can simplify maintenance tasks, allowing for quicker identification of issues and quicker resolutions. Whether you’re performing regular inspections or addressing specific malfunctions, this tool provides clarity and guidance. Understanding the layout and connections between various components enhances your ability to properly care for the machine and extend its lifespan.

Kubota ZD326 Parts Breakdown

Understanding the internal structure of any machinery is essential for both efficient operation and proper maintenance. By breaking down each essential element, you gain valuable insight into how the components interact and contribute to the overall functionality. This knowledge simplifies the repair process and helps maintain peak performance over time.

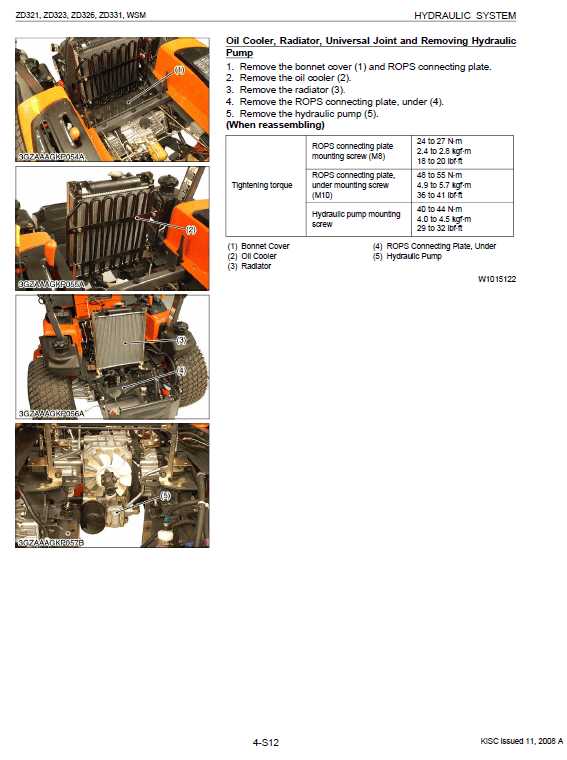

Key Mechanical Components

The primary mechanical elements are responsible for the movement and power transmission within the system. These include the engine, transmission, and wheel drive mechanisms, each of which requires periodic inspection and maintenance. Ensuring that these components are in good working order is vital for avoiding performance issues and mechanical failures during operation.

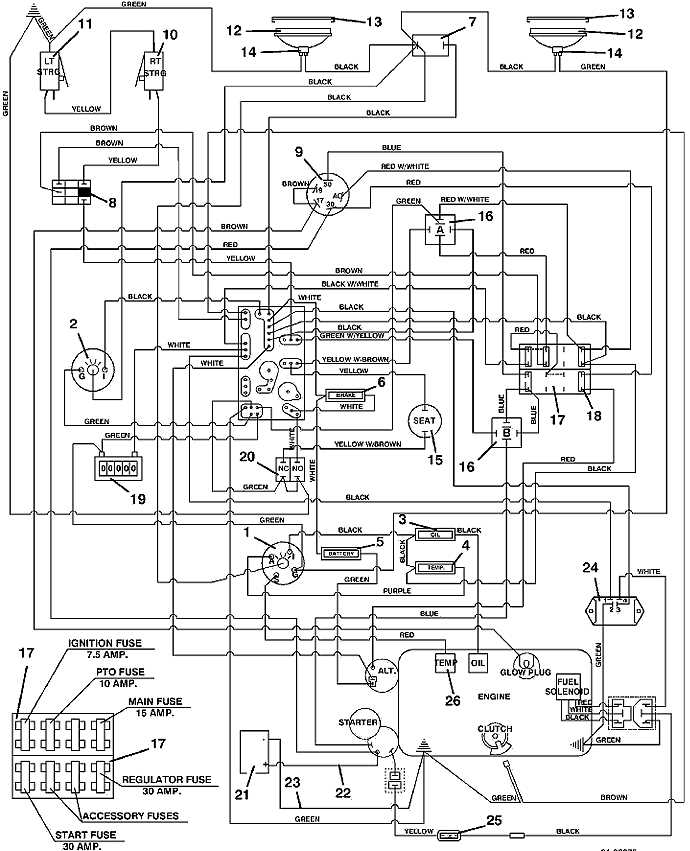

Electrical System Overview

The electrical system plays a pivotal role in the operation of various functions, including ignition, lighting, and the control systems. Proper maintenance of the wiring, fuses, and switches ensures that the equipment remains responsive and safe to use. Regular checks and updates can prevent electrical malfunctions that might otherwise disrupt normal operations.

Understanding the Kubota ZD326 Components

Familiarity with the core components of a machine is essential for efficient maintenance and repair. Each part plays a specific role in the overall operation, and recognizing how they work together enhances the ability to troubleshoot and resolve issues effectively. By understanding these key elements, operators can ensure their equipment runs smoothly and efficiently for an extended period.

The various sections, such as the engine, transmission, and control systems, are designed to perform specific functions. Knowing how to assess each component and when to service them is crucial for maintaining high performance. This knowledge also helps in identifying potential wear and tear, preventing unexpected breakdowns that could disrupt operations.

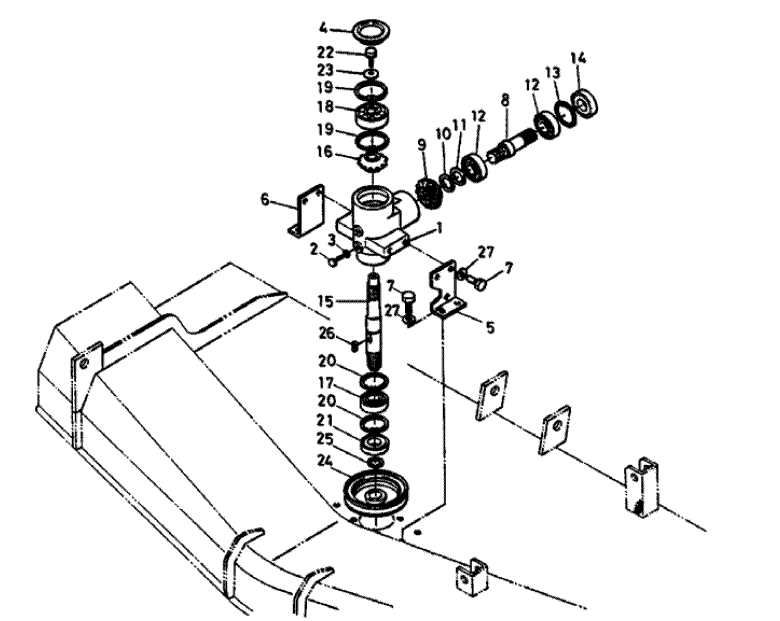

How to Use the Parts Diagram Effectively

Utilizing a visual guide for machinery components can greatly enhance the efficiency of maintenance tasks. It provides a clear reference for identifying individual elements and understanding their connections within the system. This method is particularly helpful for troubleshooting, repairs, and ensuring proper reassembly after servicing.

To use such a reference effectively, start by familiarizing yourself with the overall layout and structure. Identify the various sections, and understand how the components interact with each other. When performing maintenance, cross-check the diagram with the physical machinery to ensure accuracy and avoid unnecessary disassembly. This approach streamlines the process, reduces errors, and ensures a more precise repair or replacement procedure.