Maintaining and repairing outdoor equipment requires a clear understanding of its individual parts and their functions. When you have a detailed view of how each piece fits together, performing maintenance or troubleshooting becomes much easier and more efficient.

Whether you’re a professional or a hobbyist, knowing how to identify key elements of your tool is crucial. A well-organized illustration of the machine’s parts can help you pinpoint potential issues and ensure proper functioning.

Familiarizing yourself with the components allows you to quickly recognize the most critical areas that need attention. Having this knowledge on hand will assist you in making informed decisions when it comes to repairs or upgrades, prolonging the life of your tool.

Understanding the Chainsaw Layout

To properly maintain and repair any tool, it is essential to have a clear understanding of its internal structure and the role of each component. A detailed layout serves as a helpful guide for anyone working with mechanical equipment, providing insight into how the various elements interact and function together.

Main Components Overview

Here are some key sections typically found in the tool layout:

- Engine assembly – the heart of the machine responsible for power generation.

- Drive mechanism – connects the engine to the working parts, allowing efficient movement.

- Air filtration system – ensures clean airflow to maintain performance.

- Fuel system – responsible for fuel delivery, including the tank and lines.

- Safety features – includes mechanisms designed to protect the user during operation.

How the Layout Helps in Maintenance

By understanding how the components are arranged, you can identify potential issues with ease. For instance, if the engine is not running smoothly, you may need to inspect the fuel system or the spark plug. When you know where each element is located and how it functions, you can troubleshoot faster and more efficiently.

- Accurate diagnosis of issues

- Easy access to critical parts for repairs

- Prolongs the life of the tool by ensuring regular maintenance

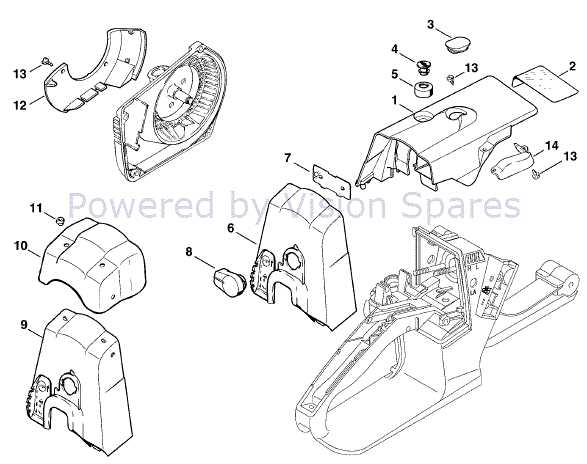

How to Use the Parts Layout Effectively

Using an equipment layout correctly is essential for both maintenance and repair tasks. It provides a visual representation of all the critical components, making it easier to identify and understand how each part functions and fits together. With this tool, you can quickly pinpoint where issues may arise and efficiently carry out repairs.

To make the most of the layout, start by familiarizing yourself with its structure. Each section is typically labeled to correspond with specific areas of the tool. This organization allows for easy navigation, ensuring that you can focus on the relevant components when troubleshooting or performing routine maintenance.

- Identify the components relevant to the problem at hand.

- Cross-reference the layout with the physical tool to locate specific parts.

- Use the labels and numbering system to ensure accuracy during assembly or disassembly.

By following these steps, you can maximize your efficiency, reduce mistakes, and ensure that your equipment remains in optimal condition for longer. Whether you’re conducting a repair or simply conducting a maintenance check, this approach simplifies the process significantly.

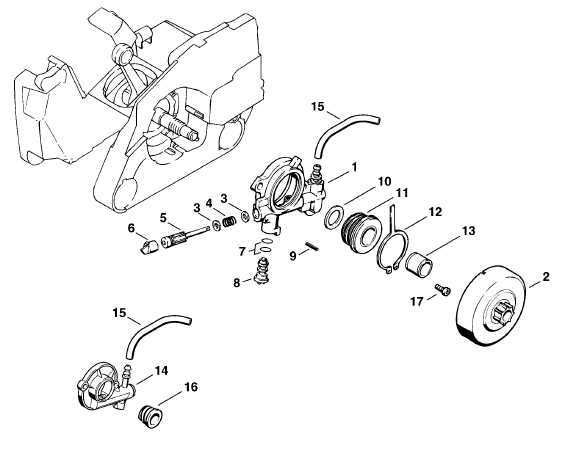

Key Components of the Chainsaw

Understanding the core elements of a chainsaw is crucial for effective maintenance and repair. Each component plays a specific role, contributing to the tool’s overall functionality. Knowing these parts and their interactions helps ensure smooth operation and quicker troubleshooting when issues arise.

The primary components of a chainsaw can be divided into several categories. From the engine to the cutting mechanism, each part needs regular inspection to maintain peak performance. Here are some of the most important elements:

- Engine – Powers the entire tool and drives the cutting chain.

- Fuel System – Supplies the engine with the necessary fuel for operation.

- Bar and Chain – The cutting components responsible for making precise cuts.

- Air Filtration System – Ensures clean airflow to the engine, enhancing performance and longevity.

- Safety Features – Includes elements like chain brakes and handguards, designed to protect the user.

Familiarity with these key components allows for efficient troubleshooting and easier identification of worn-out or damaged parts. By regularly inspecting and understanding the role of each part, you can prevent issues before they affect performance.