Every mechanical device consists of numerous elements that work together to ensure its smooth operation. Understanding how these individual components interact can significantly enhance your ability to maintain and repair your equipment efficiently. Having a clear overview of each part’s function and placement makes the troubleshooting process much easier, whether you’re dealing with a malfunction or performing regular upkeep.

Identifying the right components and knowing where each piece fits within the overall structure can save time and prevent errors during repairs. With the right knowledge, you can confidently replace or adjust parts, ensuring that the tool remains in top working condition for an extended period.

Proper maintenance is crucial for extending the lifespan of any mechanical tool. In this guide, we will explore how to read and interpret the component layout, identify common issues, and provide solutions for effectively managing your equipment. Mastering this knowledge empowers you to take control of your tool’s performance and ensures that it continues to serve you well throughout its use.

Understanding Your Tool’s Components

Each tool is made up of several key elements that work together to ensure optimal performance. Recognizing the function of each individual component is essential for understanding how the device operates as a whole. Knowing the role of each piece allows you to troubleshoot more effectively, identify faults, and make precise repairs when necessary.

By familiarizing yourself with the layout of these essential components, you can more easily navigate the repair or maintenance process. From the motor to the smallest fasteners, every element contributes to the overall function, and knowing where each part fits can save both time and effort during any required fixes.

Whether you’re performing basic upkeep or addressing a specific issue, understanding the components’ arrangement and how they interact is key. This knowledge will allow you to maintain your tool’s efficiency and ensure it remains reliable over time.

How to Read the Components Layout

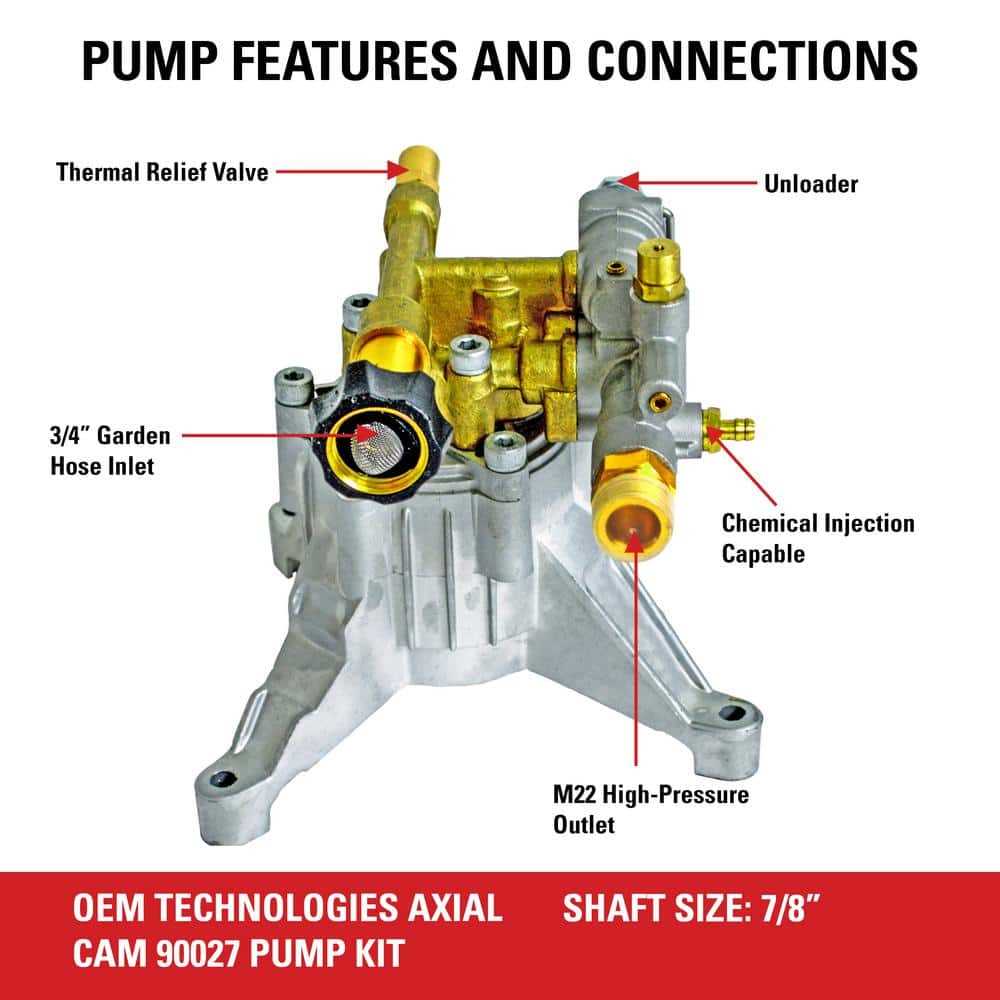

Understanding how to interpret a visual representation of your tool’s internal structure is crucial for effective maintenance and repairs. These illustrations provide a detailed look at how each individual element is positioned and connected within the device. By learning to read these layouts, you can easily identify each part, making it simpler to locate replacements or assess any issues that may arise.

Identifying Key Elements

Each visual guide will highlight the various components in an organized way, often numbering them for clarity. The first step in reading the layout is to recognize the symbols or labels that correspond to specific sections of the tool. These labels are typically grouped by their function, allowing you to locate critical parts quickly. Pay close attention to these markers as they indicate which pieces are crucial for disassembly or repair.

Understanding the Flow of Connections

Another important aspect of reading these layouts is understanding how the various components are linked together. The lines or arrows that connect the elements demonstrate how the parts interact during operation. By following these connections, you can gain insights into the tool’s functionality, which will aid in diagnosing problems. Recognizing these interdependencies is essential for a successful repair or replacement process.

Common Issues and Replacement Components

Over time, every tool may experience issues that require attention. Recognizing common malfunctions and knowing which elements to replace can make a big difference in how quickly and effectively you address the problem. This section explores some of the most frequent issues encountered and highlights the components that typically need to be replaced during repairs.

Frequent Mechanical Failures

One of the most common problems tools face is motor failure. This can happen due to wear and tear, overheating, or a buildup of debris. In such cases, the motor or its related components may need to be replaced to restore functionality. Similarly, issues with switches or wiring can cause inconsistent power flow, requiring the replacement of electrical parts to ensure proper operation.

Damage to External and Internal Elements

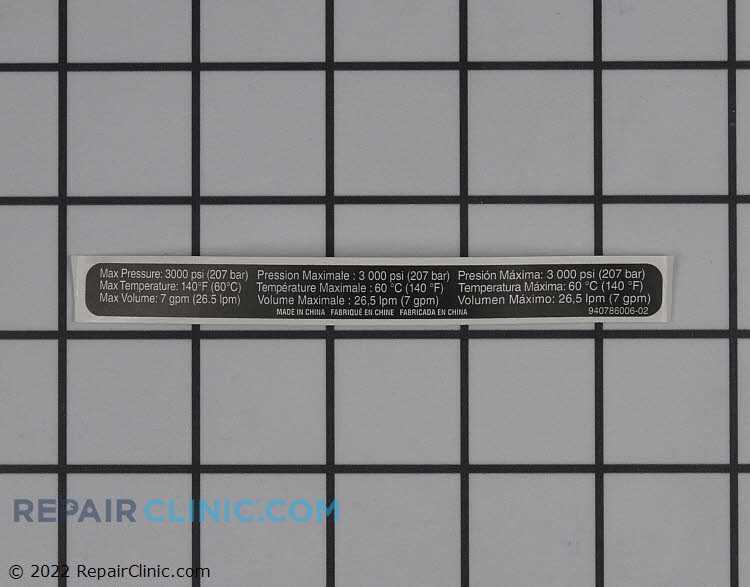

External parts, such as handles or casings, are also prone to damage from impact or prolonged use. Cracked or broken housing often leads to further internal damage if not addressed promptly. Additionally, internal components like gears, fasteners, or seals may wear out over time, requiring replacements to prevent further malfunctions. Ensuring these parts are in good condition is essential for maintaining the overall integrity of the tool.