Proper knowledge of your machinery is key to its effective operation and longevity. Understanding each element of the system can help prevent issues and ensure smoother performance. Identifying the components and their functions is the first step in achieving optimal results, whether you’re working on a professional project or completing DIY tasks at home.

Maintaining functionality is easier when you know what each part does and how it interacts with others. Regular maintenance and occasional repairs are essential to keep your equipment in top shape, especially when used frequently. A clear grasp of the internal structure aids in troubleshooting and resolving issues quickly.

Familiarizing yourself with the correct assembly and disassembly process also plays a vital role in extending the life of your device. Whether you’re dealing with clogs, leaks, or other mechanical problems, having a reference point for each element can significantly improve the efficiency of your repairs.

Understanding Krause and Becker Parts

Having a clear understanding of the components that make up your equipment is crucial for its efficient operation. Each element plays a unique role in ensuring the device functions properly, so it’s essential to know how they work together. Recognizing these elements allows for better troubleshooting, repair, and maintenance.

Familiarity with the components helps you identify potential issues before they become serious problems. Whether it’s a simple wear-and-tear issue or a malfunctioning part, knowing how everything fits together will enable you to resolve issues more quickly. Regular checks of individual parts can prevent unnecessary damage and costly repairs.

Understanding the assembly process is also beneficial when it comes to cleaning and reassembling the machine. Knowing the correct order and placement of each element ensures that everything is back in its proper position, minimizing the risk of errors. This knowledge will ultimately lead to improved performance and longevity of your equipment.

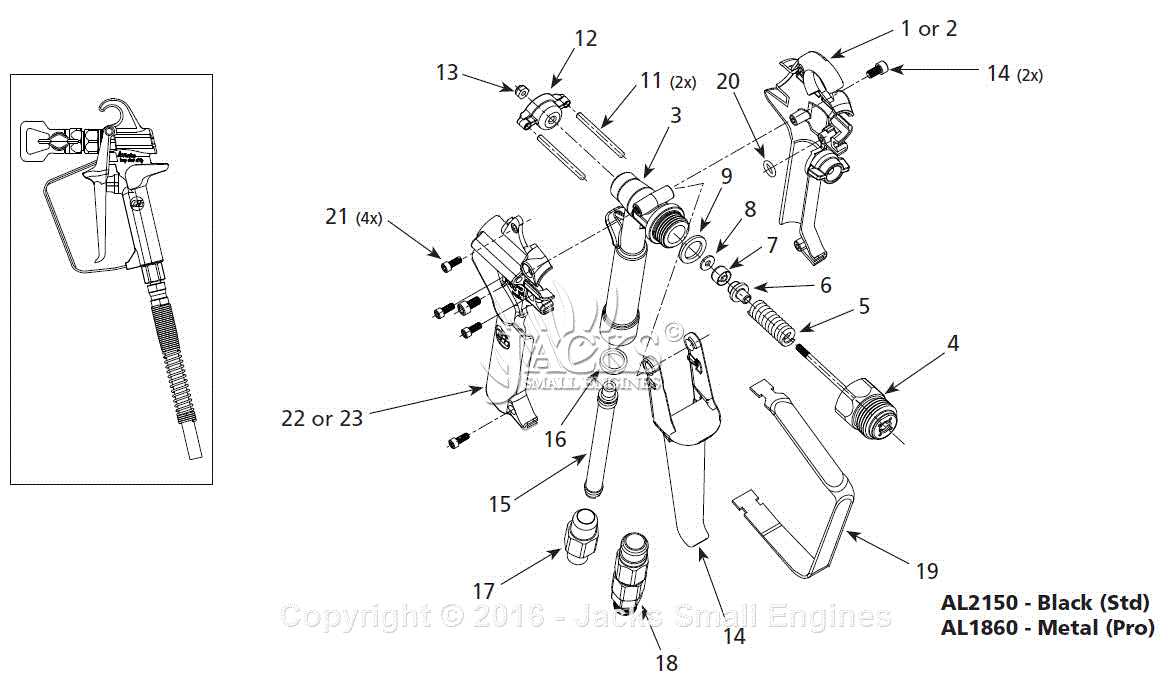

Identifying Key Components in the Diagram

When working with any complex machine, knowing how to identify the essential elements that make up the system is vital. Each part serves a specific function, and understanding their role can greatly enhance your ability to maintain and troubleshoot the equipment. A clear understanding of the key components helps in recognizing potential issues early and addressing them efficiently.

Recognizing Major Functional Elements

The main functional elements of the system are the core components that drive its performance. Recognizing these parts, such as the mechanism responsible for fluid movement or the regulating system, can help you pinpoint areas that may need attention. Each element is typically designed to perform a unique job, and their interconnection is crucial for optimal functionality.

Detailed Inspection for Wear and Tear

Regular inspection of each element is necessary to spot signs of wear and tear. Some components may show visible damage, such as cracks or abrasions, while others may exhibit performance degradation. Understanding the relationship between these parts can help you identify when something is out of place or functioning incorrectly, allowing for more effective maintenance and repair.

Maintaining Your Equipment

Proper upkeep of your machinery is crucial for ensuring long-term functionality and preventing costly repairs. Regular maintenance helps avoid unexpected breakdowns and keeps your device working efficiently. By following a routine care schedule, you can extend the lifespan of the equipment and maintain optimal performance.

Cleaning and Lubricating the Key Mechanisms

Routine cleaning is essential to prevent the buildup of debris or residue that can cause clogging and performance issues. Be sure to clean all moving parts, ensuring that there is no accumulation of foreign materials that could interfere with the operation. Additionally, lubricating the critical components helps reduce friction, ensuring smoother movement and reducing the risk of wear over time.

Checking for Wear and Replacing Components

Regularly inspect the system for signs of wear, such as cracks, leaks, or signs of fatigue in key parts. Identifying these issues early allows for timely replacement of damaged or worn-out elements, preventing further damage to the equipment. Stay ahead of potential problems by replacing compromised parts as needed to keep the system running at peak efficiency.