When it comes to maintaining outdoor machinery, understanding the structure and individual components is essential for efficient repairs. A clear breakdown of parts is crucial for both identifying faulty areas and performing proper maintenance. With this knowledge, you can tackle any issue with confidence, ensuring long-lasting performance and functionality.

Whether you’re replacing worn-out pieces or reassembling the unit after servicing, having a detailed reference guide is invaluable. This visual representation helps pinpoint the correct parts, their location, and their connections. Equipped with this, you can quickly solve problems and prevent future breakdowns, saving time and effort in the process.

Understanding the layout of your machine can significantly improve your ability to troubleshoot, while also minimizing the need for professional repairs. With a comprehensive overview, you’ll be better prepared for any challenge that may arise during the maintenance process.

Understanding the Toro 75755 Parts Diagram

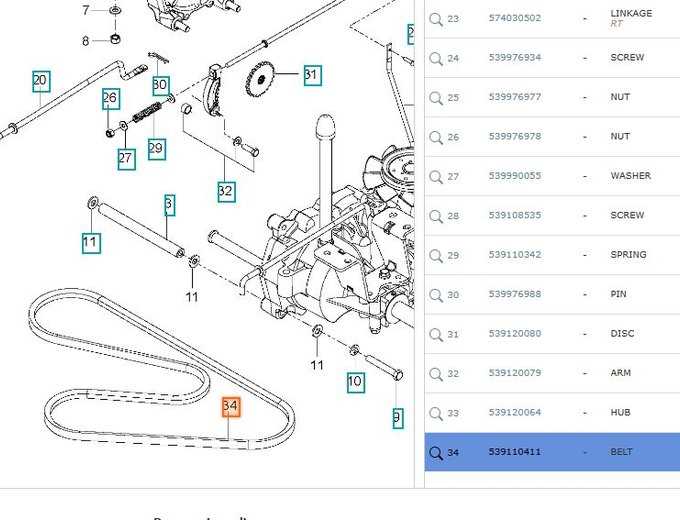

Having a detailed visual breakdown of your outdoor equipment’s components plays a key role in effective maintenance and repair. This guide provides a clear representation of the various elements involved, allowing users to identify and understand the relationships between each part. With this knowledge, the process of troubleshooting or replacing broken pieces becomes more straightforward and less time-consuming.

Key Features and Components

The first step in utilizing the schematic is recognizing the critical parts that keep the equipment functioning. Each component has a specific role, and understanding their placement helps in isolating issues. Whether it’s a damaged section that needs replacing or a part that requires adjustment, being able to spot these areas quickly ensures smoother repairs.

Step-by-Step Repair Process

Once the key components are identified, the next phase involves understanding the assembly process. A visual guide is invaluable for reassembling the equipment after repairs or replacements, ensuring that everything fits together correctly. Following a step-by-step approach allows for a precise reassembly, minimizing the risk of errors and ensuring the machine operates as intended.

Identifying Key Components for Repairs

Effective repairs begin with the ability to quickly identify the key components that need attention. By understanding the structure of your machine and the function of each part, you can pinpoint the areas that are causing issues. This knowledge is essential for both routine maintenance and more complex repair tasks.

Common Problem Areas

Some components are more prone to wear and tear due to their frequent use. Identifying these areas early on can prevent further damage and reduce repair time. These parts often require regular checks and timely replacements to ensure smooth operation. Knowing which parts to monitor closely can save both time and effort in the long run.

Using Visual References for Accuracy

Visual references, such as clear schematics or detailed guides, help accurately locate and understand each part’s role within the machine. These resources provide a clear view of how everything fits together, making it easier to spot the faulty areas. With a visual aid, repairs become more manageable, and the risk of missing a damaged part is minimized.

Step-by-Step Guide to Assembly

Reassembling your equipment after maintenance or repairs requires a structured approach to ensure all components are correctly positioned and connected. A clear, methodical process helps in restoring the unit to its optimal functioning state. By following a step-by-step guide, you can avoid mistakes and minimize the chances of errors during reassembly.

Organizing Components Before Assembly

Before starting the assembly process, it’s essential to lay out all components in an organized manner. This allows for quick identification and ensures that no part is overlooked. Careful organization also helps in determining if any parts are missing or damaged before reassembly begins.

Reassembling in Logical Sequence

Begin the reassembly by following a logical order, starting with the larger components and working your way down to the smaller ones. This method ensures that you do not encounter space constraints or difficulties when connecting pieces. Patience and attention to detail are key during this phase, as every part must be secured properly to maintain the unit’s overall integrity and performance.