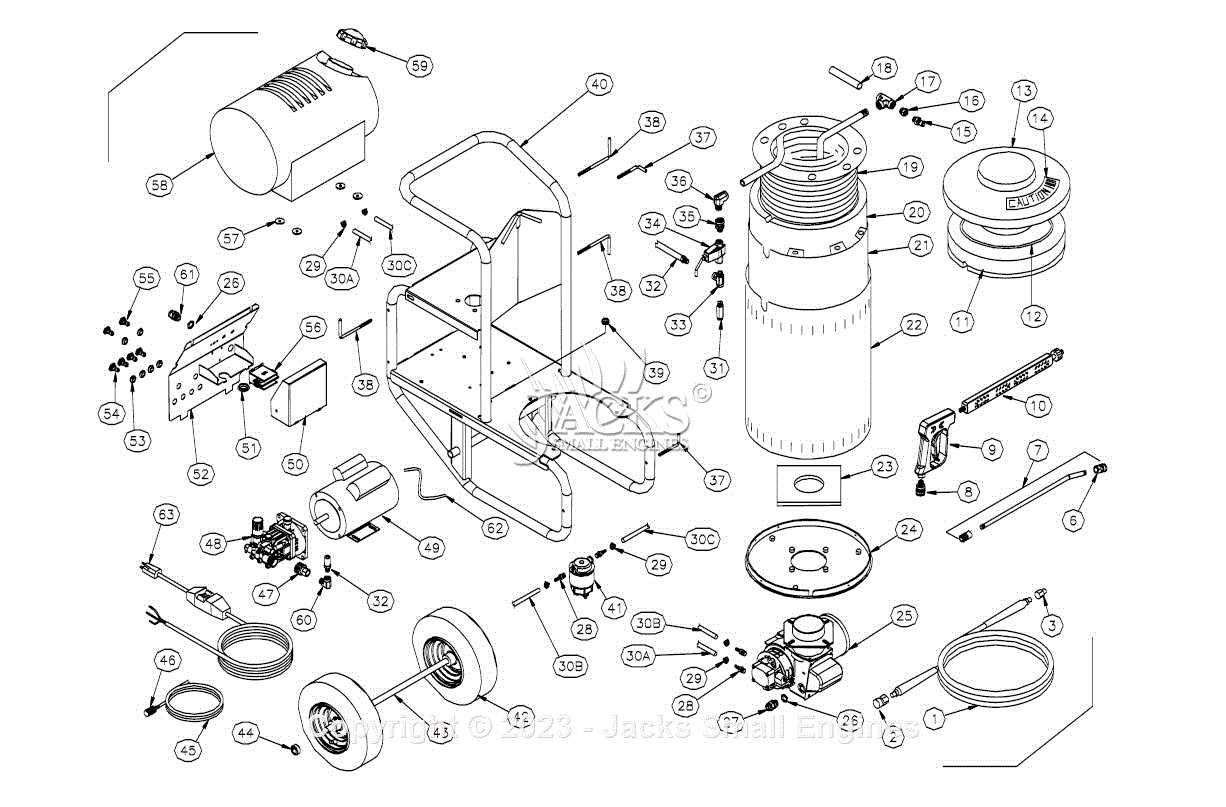

Every effective cleaning tool relies on a well-designed system of interconnected elements that work together to ensure optimal functionality. Understanding the internal structure of these devices is essential for both proper maintenance and repair. By familiarizing yourself with the different components, you can improve the longevity and performance of your equipment.

In this section, we will explore the various components of a cleaning device and how they function in unison. Whether you’re aiming to troubleshoot an issue or perform routine upkeep, knowing the role of each piece will help you make informed decisions. From the main housing to smaller connectors, each part contributes to the overall efficiency of the tool.

Learning the specifics of each element is crucial for anyone looking to extend the lifespan of their equipment or resolve common issues that may arise. This guide provides a clear overview of the essential features and will assist you in mastering the details that ensure your device continues to operate at its best.

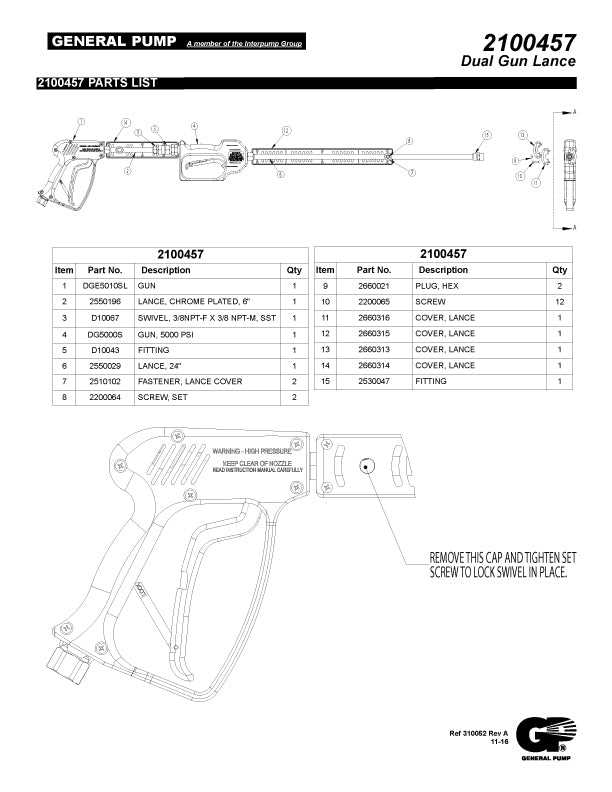

Understanding Pressure Washer Gun Components

The effectiveness of any cleaning device depends on the seamless coordination of its various elements. Each individual component plays a specific role in delivering the high performance expected from these tools. Understanding how these pieces interact is essential for maintenance and repair, ensuring the equipment continues to function smoothly and efficiently.

Key Elements of the System

At the heart of any cleaning tool are the mechanisms that control water flow and pressure. These include valves, nozzles, and connectors that work together to direct and regulate the output. Valves control the flow, ensuring that water is delivered consistently, while nozzles are designed to focus or disperse the stream for different cleaning tasks. The connectors play a vital role in linking these elements securely to prevent leaks and maintain pressure levels.

Maintenance and Troubleshooting

Proper care of each component is essential for the longevity and performance of the tool. Regular inspection of seals, connectors, and internal mechanisms will help identify potential issues before they lead to significant malfunctions. Lubricating moving parts and replacing worn-out seals will reduce the risk of failure and ensure that the system operates at full capacity. Understanding the function of each component makes it easier to diagnose and fix common problems.

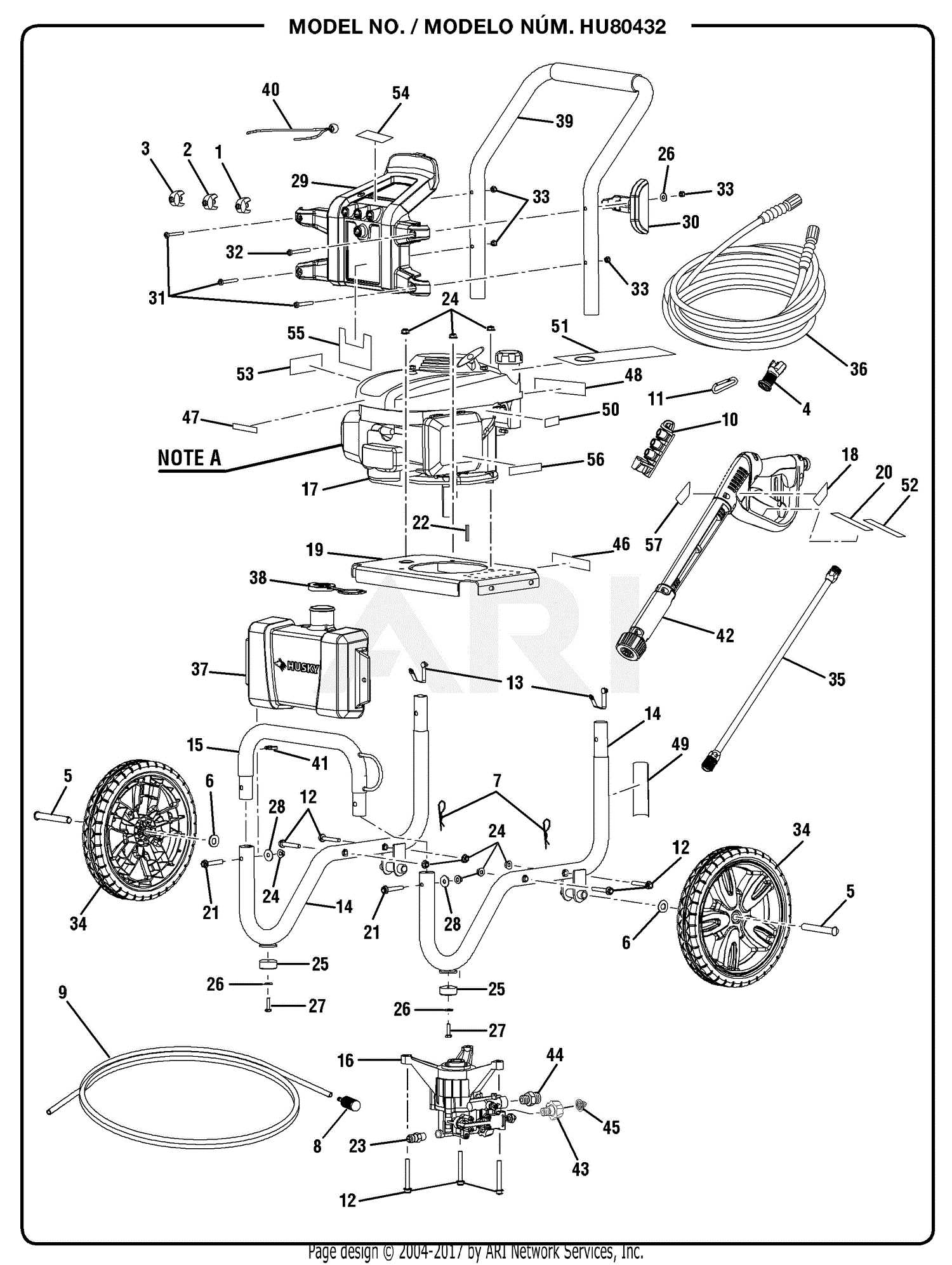

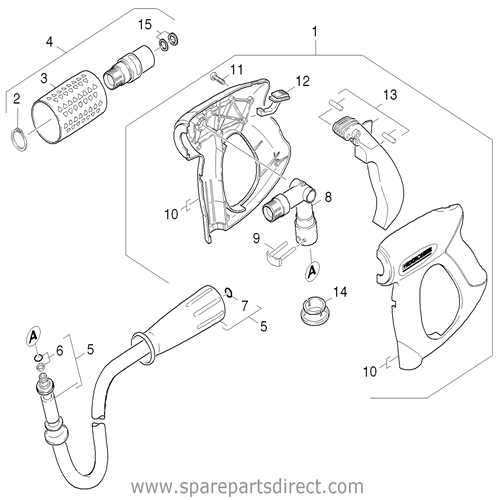

How to Identify Key Parts of the Trigger Gun

Recognizing the essential components of a cleaning tool is the first step in understanding its functionality and ensuring its efficient operation. Each element, from the main structure to the smaller attachments, serves a specific purpose. By familiarizing yourself with these key parts, you can troubleshoot issues, replace faulty components, and perform general maintenance tasks effectively.

Examining the Core Components

The main housing is the foundation of the tool, where other elements are securely attached. Look for the handle, which provides the user with control, and the nozzle connections, where water is directed. Additionally, the valve system regulates the flow of water, controlling how it is expelled. Understanding the location and function of each part is essential for proper operation and repairs.

Locating Smaller Attachments

Smaller accessories, such as nozzles and connectors, may seem insignificant but play crucial roles in the cleaning process. These pieces often determine the type of spray or pressure delivered. Identifying them and ensuring they are in good condition is vital for maintaining the efficiency of the entire system.

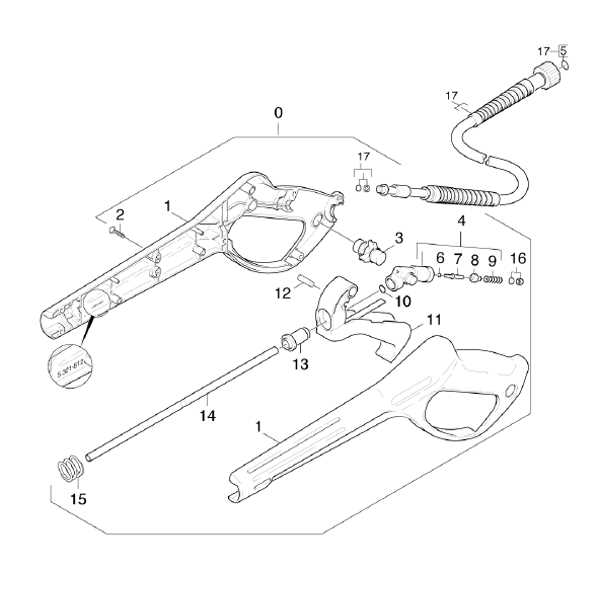

Step-by-Step Guide to Pressure Washer Gun Repair

Repairing a cleaning tool involves understanding its structure and identifying any faulty elements that may hinder performance. Whether it’s a minor issue like a leaking connection or a more complex malfunction, following a systematic approach will help restore the equipment to optimal working condition. This guide outlines the essential steps to troubleshoot and repair common problems efficiently.

Diagnosing the Problem

Start by thoroughly inspecting the tool to identify any visible issues. Check for leaks around seals and connectors, as these are common sources of malfunction. If the flow is inconsistent, inspect the internal valve system for blockages or wear. Identifying the source of the issue is crucial before proceeding with any repairs.

Performing the Repair

Once the issue is diagnosed, begin by disassembling the affected area carefully. For leaks, replace any damaged seals and ensure all components are properly aligned. If the flow is irregular, clean or replace any obstructed parts in the internal mechanism. Reassemble the tool, ensuring all pieces are securely fitted. After completing the repair, test the device to confirm that it operates smoothly.