When maintaining heavy-duty machinery, having a clear understanding of its components is crucial for efficient repairs and troubleshooting. Knowing how various elements fit together allows you to perform tasks with precision, minimizing downtime and costly repairs. Each machine consists of numerous interconnected parts, all of which serve specific functions essential to its overall performance.

By familiarizing yourself with visual guides and reference materials, you can quickly identify key components and their roles. These tools provide a roadmap for understanding where specific elements are located and how they interact. Whether you are performing routine maintenance or handling an urgent repair, this knowledge streamlines the process and ensures your equipment continues to operate at its best.

Proper maintenance relies on being able to pinpoint issues effectively. With detailed illustrations and comprehensive manuals, even complex machinery becomes more approachable. This guide will help you break down the essential features of your equipment, making repairs and upkeep simpler and more efficient.

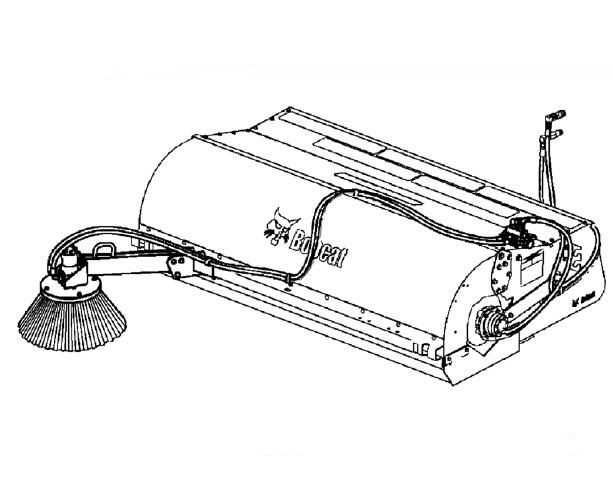

Understanding Bobcat Sweeper Components

To ensure optimal performance of your equipment, it is essential to grasp the various elements that contribute to its operation. Each component plays a distinct role, working in unison to maintain the machinery’s functionality. By understanding how these elements interact, you can identify issues more effectively and perform repairs with greater precision.

At the core of every machine are key components such as the brush assembly, motor, and drive system. These parts work together to deliver the intended results, whether it’s cleaning, clearing debris, or other tasks. Understanding their function allows for more efficient troubleshooting when something goes wrong.

Moreover, every machine’s design includes intricate connections and mechanisms that enable smooth operation. Knowing how each part fits into the overall system helps you anticipate wear and tear, extend the life of your equipment, and make informed decisions during maintenance. Regular checks and understanding the internal layout can prevent more significant issues down the line.

How to Read Bobcat Sweeper Diagrams

Interpreting technical visuals is a valuable skill when it comes to maintaining and repairing machinery. These illustrations offer a clear representation of how different elements are arranged and connected. By understanding how to read these guides, you can quickly locate specific components and gain a deeper understanding of their function within the system.

Breaking Down the Visuals

When examining a technical visual, pay attention to the labels and symbols used. These are designed to indicate the specific function or type of each part. The clear markings help identify essential components like the motor, drive system, and other mechanical sections. A good understanding of these symbols is crucial for navigating the diagram efficiently.

Using the Guide for Repairs and Maintenance

These visuals are not just for identifying parts but also serve as a helpful tool during troubleshooting. By following the connections shown, you can pinpoint potential areas of malfunction. Regularly referring to these resources during maintenance will ensure that you keep the system in optimal working condition. Additionally, accurate interpretation of these illustrations allows for quick and precise repairs, reducing downtime and minimizing the risk of further damage.

Common Bobcat Sweeper Parts and Functions

Every piece of machinery relies on specific components to perform its tasks efficiently. These components, although diverse, work together to ensure that the machine operates smoothly and meets performance expectations. Understanding the role of each part is essential for proper maintenance and troubleshooting.

One of the most important elements is the rotating brush assembly, which is responsible for clearing debris from surfaces. It makes direct contact with the ground, collecting dirt and materials while the machine is in operation. The motor that powers the system plays a critical role in driving the brush and other connected mechanisms, ensuring they work in harmony.

The drive system, another key component, transfers power from the motor to the wheels, enabling the machine to move and maneuver effectively. The wheels themselves, along with the steering system, provide mobility and control during operation. Proper functioning of these components is essential for maneuverability, especially in tight spaces or rough terrain.