When it comes to maintaining boating systems, having a clear understanding of the components involved is crucial. This guide will help you explore the essential elements that make up the mechanism responsible for adjusting and positioning the motor effectively. Familiarity with these elements allows for smoother repairs and enhanced performance.

Proper identification of each element is essential for ensuring your boat operates at its best. Whether you’re troubleshooting or replacing parts, knowing how each component functions in the system is key to keeping your vessel in top condition. This breakdown will provide an easy-to-follow map of the most important elements of the mechanism.

As you continue through this guide, you will gain valuable insight into the layout and functionality of each part, allowing for more efficient maintenance and repair processes. With the right knowledge, you can confidently tackle any necessary work with ease and precision.

Understanding the Adjusting Mechanism

In the world of boating, the ability to efficiently manage the positioning of the engine is essential for smooth operation and performance. The adjusting system allows for quick elevation and lowering, ensuring that the motor can adapt to various water conditions. This mechanism plays a crucial role in ensuring the engine functions optimally throughout different phases of boating.

Core Functionality

The system is designed to provide controlled movement, enabling the motor to move up and down in response to various environmental conditions. By manipulating this mechanism, boaters can avoid obstacles, improve fuel efficiency, and maintain engine protection during navigation. The proper functioning of this system ensures seamless control over boat propulsion and steering.

Key Components Involved

Several elements work together to form the system, each playing a unique role in achieving precise movements. Hydraulic pumps, pistons, and control switches allow for accurate positioning and responsiveness. Understanding the relationship between these components is vital for performing maintenance and ensuring long-lasting operation. Familiarity with the functionality of each part helps identify potential issues early, making repairs more straightforward.

Identifying Key Adjusting System Components

To maintain and repair the adjusting mechanism effectively, it’s important to understand the essential elements that make up the system. These components work together to facilitate smooth operation and ensure proper engine positioning. Each part plays a specific role in achieving accurate adjustments, and recognizing them is key to troubleshooting and repairs.

The core system consists of several vital elements, including hydraulic pumps, control valves, switches, and pistons. These components interact to provide precise control over the engine’s position, enabling quick and reliable changes based on the boat’s needs. Being familiar with each element’s function helps ensure the system operates without issues and remains durable over time.

For efficient maintenance, it’s important to be able to spot wear and tear in these components. Regular inspection helps to identify potential problems before they lead to major issues. Understanding how each part contributes to the overall function allows for easier diagnosis and faster repairs, ensuring the boat remains in peak condition.

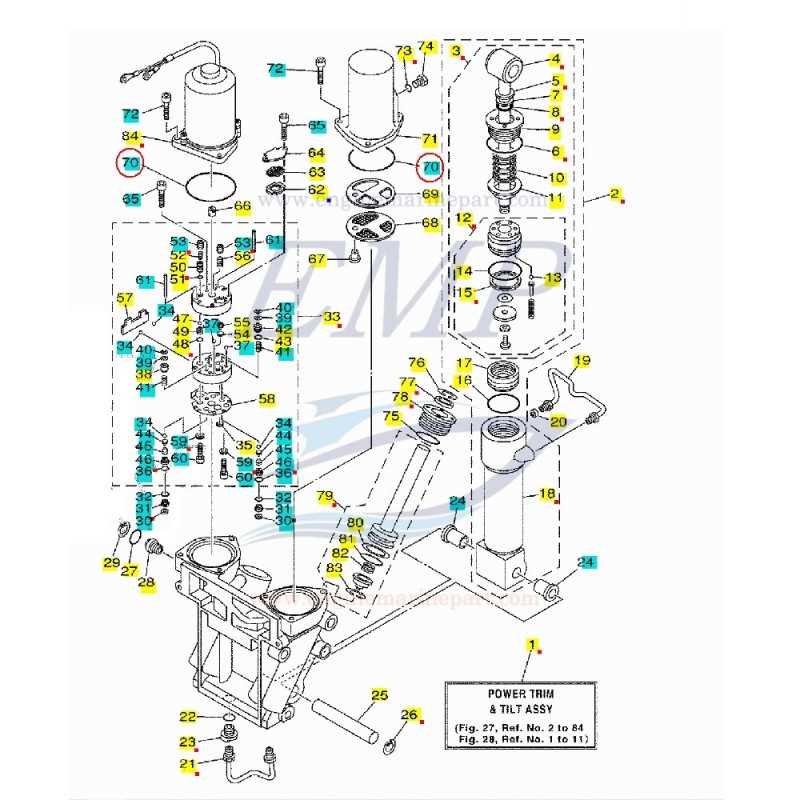

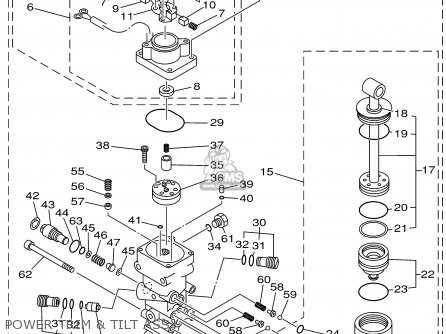

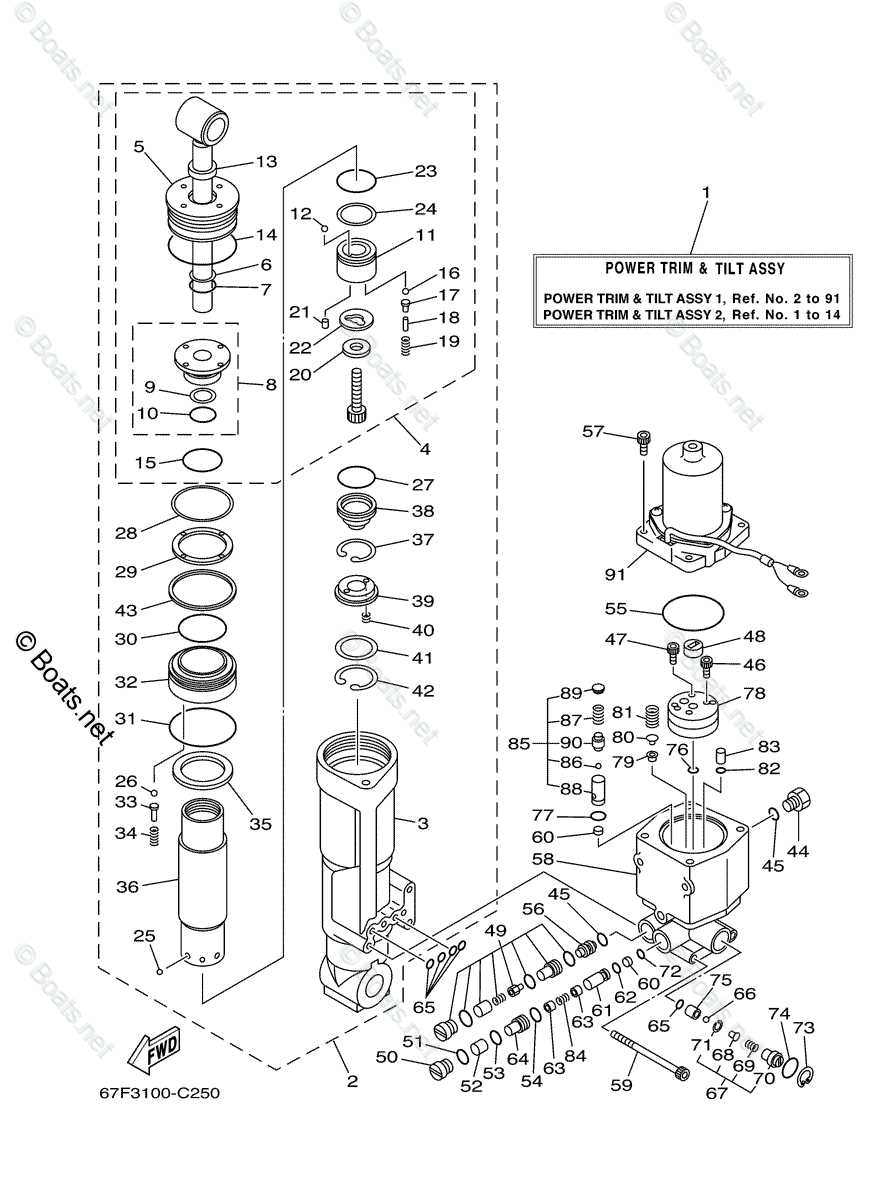

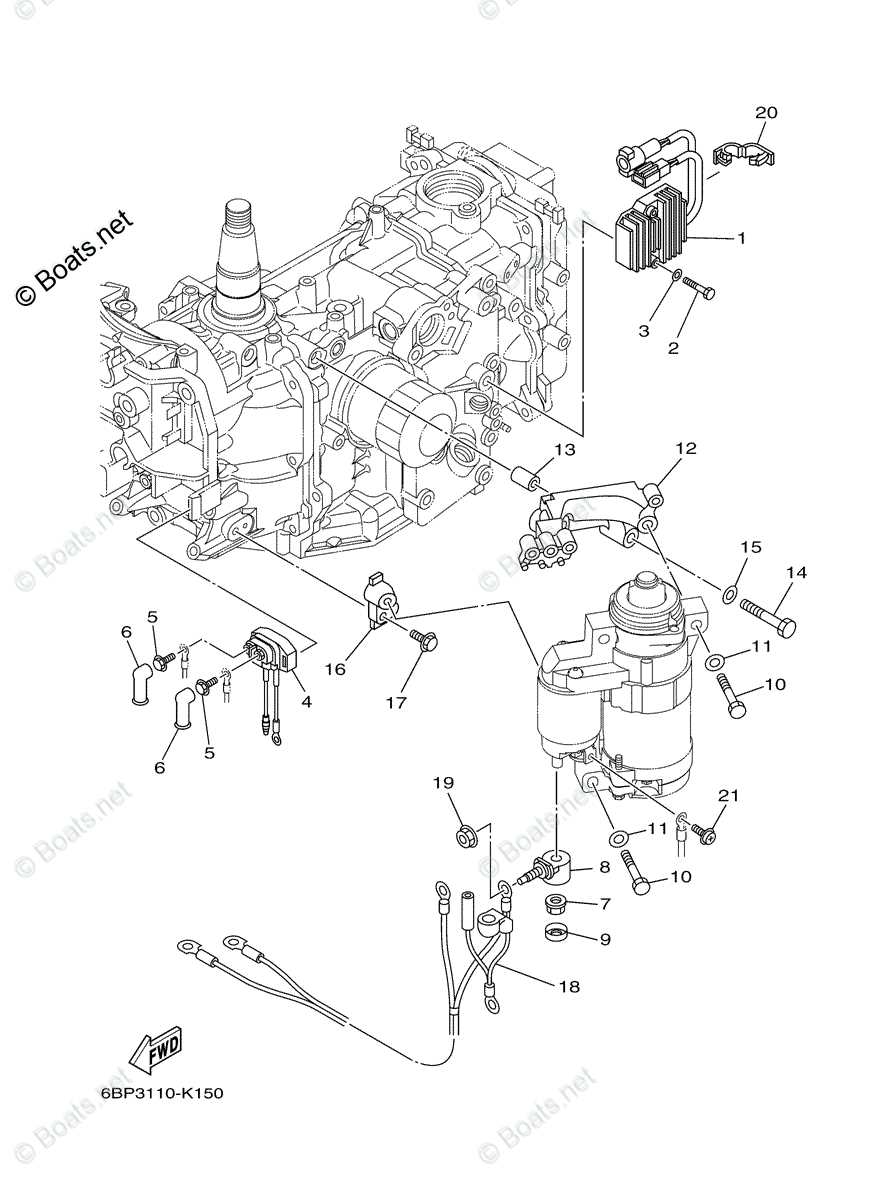

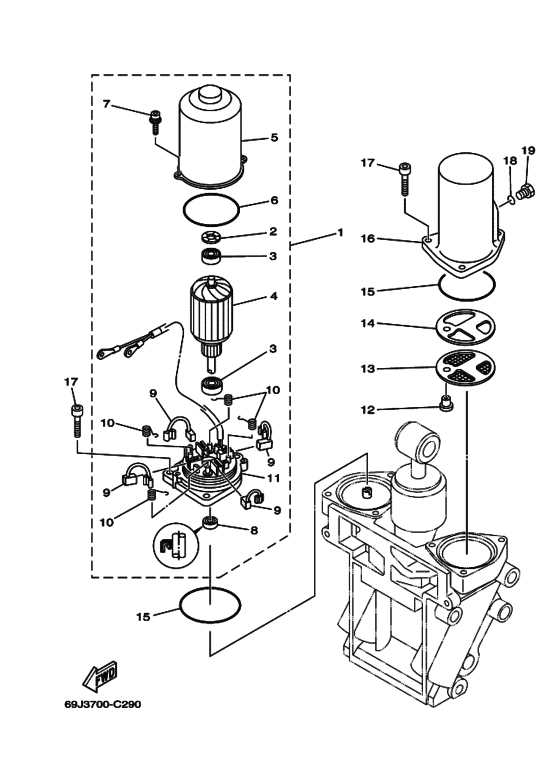

How to Interpret the System Layout

Understanding the layout of the components is essential for performing repairs and maintenance. A detailed illustration serves as a map, showing how each part fits into the overall structure. Being able to read and interpret this layout can significantly simplify troubleshooting and ensure proper replacements are made when needed.

Start by identifying each component’s label, usually accompanied by a reference number. These labels help you match the items on the layout with those physically present in the system. The reference numbers typically correspond to a parts list, making it easier to find the exact components needed for replacement or repair.

Another crucial aspect is understanding the connections between the components. The diagram often shows how various parts interact with each other, helping you pinpoint issues such as leaks or misalignments. By recognizing these relationships, you can take a more targeted approach to maintenance, ultimately saving time and effort.