When it comes to maintaining and repairing outdoor equipment, having a clear understanding of its internal structure is essential. Knowing where each component fits and how they interact ensures smoother operation and faster troubleshooting. Whether you’re a seasoned technician or a DIY enthusiast, recognizing the individual elements can make all the difference in effective maintenance.

Accurate identification of these components is crucial, as it allows for targeted repairs and replacements, minimizing downtime and improving efficiency. Understanding how to interpret the layout of a machine’s inner workings can save both time and effort, especially when working with complex systems. This guide will break down the key elements, helping you become familiar with each piece and how they contribute to the overall functionality.

By familiarizing yourself with these essential components, you can avoid costly mistakes and enhance the longevity of your equipment. Whether it’s for simple repairs or routine servicing, this knowledge will help you get the most out of your tools, ensuring that they perform optimally throughout their lifespan.

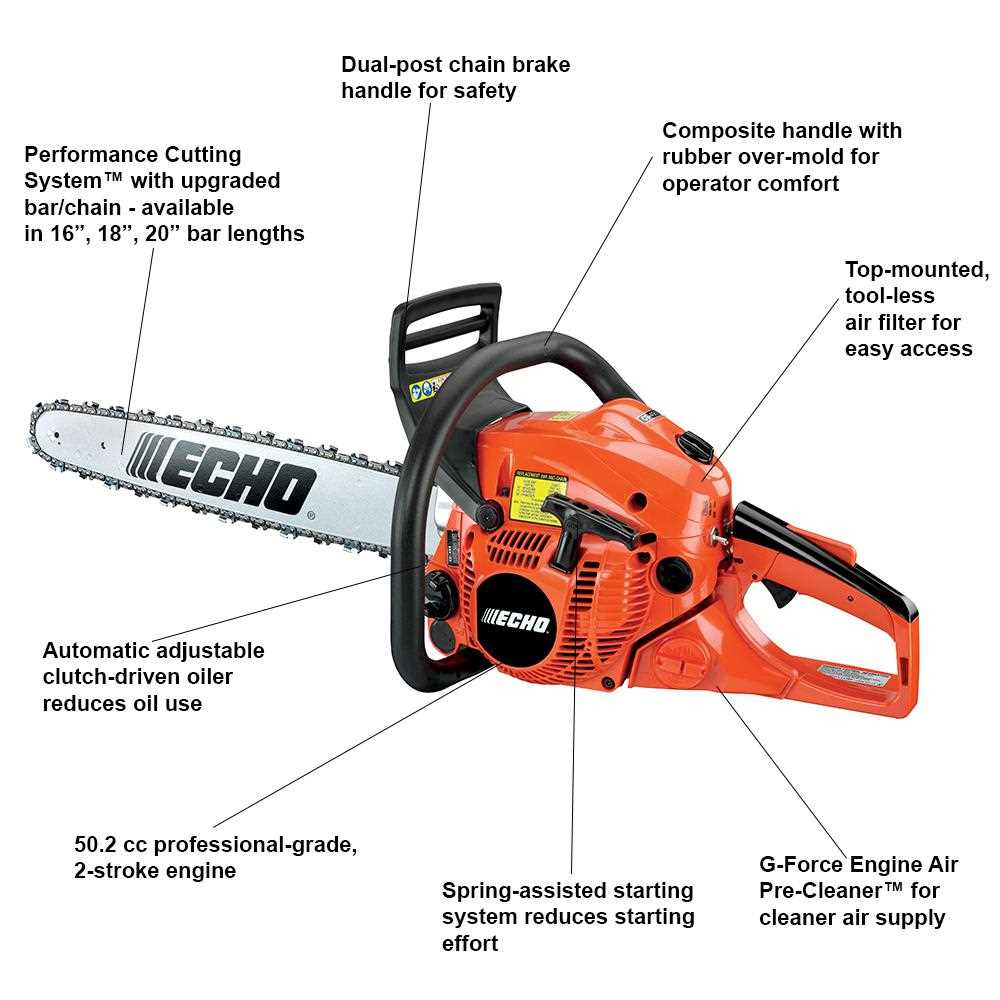

Understanding the Key Components of Echo Chainsaws

Every piece of outdoor equipment is made up of several crucial elements that work together to deliver optimal performance. Familiarity with these components can help users maintain and repair their tools efficiently. The internal structure includes a variety of mechanical and electrical parts that each serve a specific function in keeping the machine running smoothly.

The engine, fuel system, and cutting mechanism are some of the core components that contribute to the tool’s overall effectiveness. Each of these elements must be properly maintained to ensure the device works as intended. Identifying potential issues early on can prevent larger problems down the line, allowing for quicker repairs and a longer lifespan for the equipment.

Having a detailed understanding of the individual components within the system is key to troubleshooting and upgrading. Knowing where each part fits in the layout allows users to perform repairs and replacements with greater precision, enhancing the tool’s reliability and efficiency in the long run.

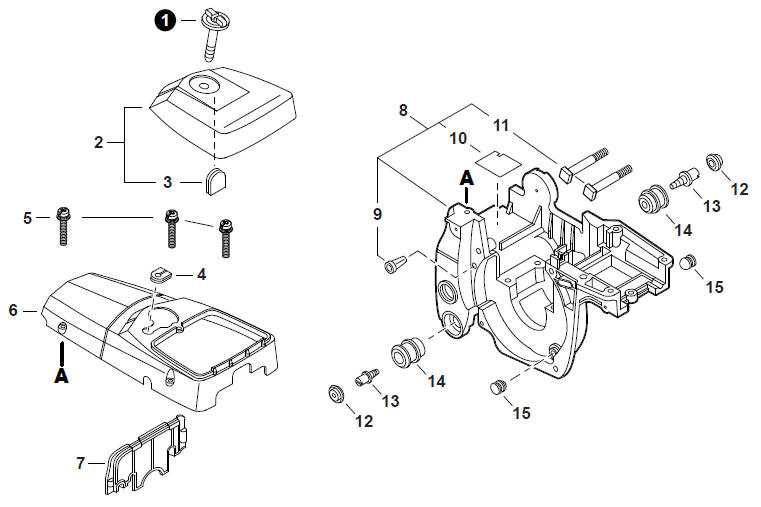

How to Read a Parts Diagram Effectively

Understanding how to interpret visual representations of an equipment’s internal components is essential for efficient repairs and maintenance. These layouts provide a clear overview of how each element is positioned and how they interact with each other. Mastering the art of reading these schematics helps you quickly identify parts, reduce errors, and streamline the troubleshooting process.

Start by Identifying Key Sections

The first step is to familiarize yourself with the different sections of the layout. Each area typically represents a specific part of the tool, and knowing the general structure will help you focus on the relevant sections for repairs. Pay attention to labels, numbers, and symbols that correspond to the components you need to work with.

Follow the Flow of Components

Next, look for how the individual parts are connected. This gives you an idea of the overall functioning system and helps you understand how parts may affect one another. By following the flow from one section to another, you’ll gain insights into assembly and disassembly processes, making your work much easier.

- Examine the legend for reference symbols.

- Note the arrows indicating movement or connections.

- Pay attention to part numbers for easy identification.

By taking these steps, you’ll be able to read and use these schematics more effectively, leading to quicker, more accurate repairs and maintenance tasks.

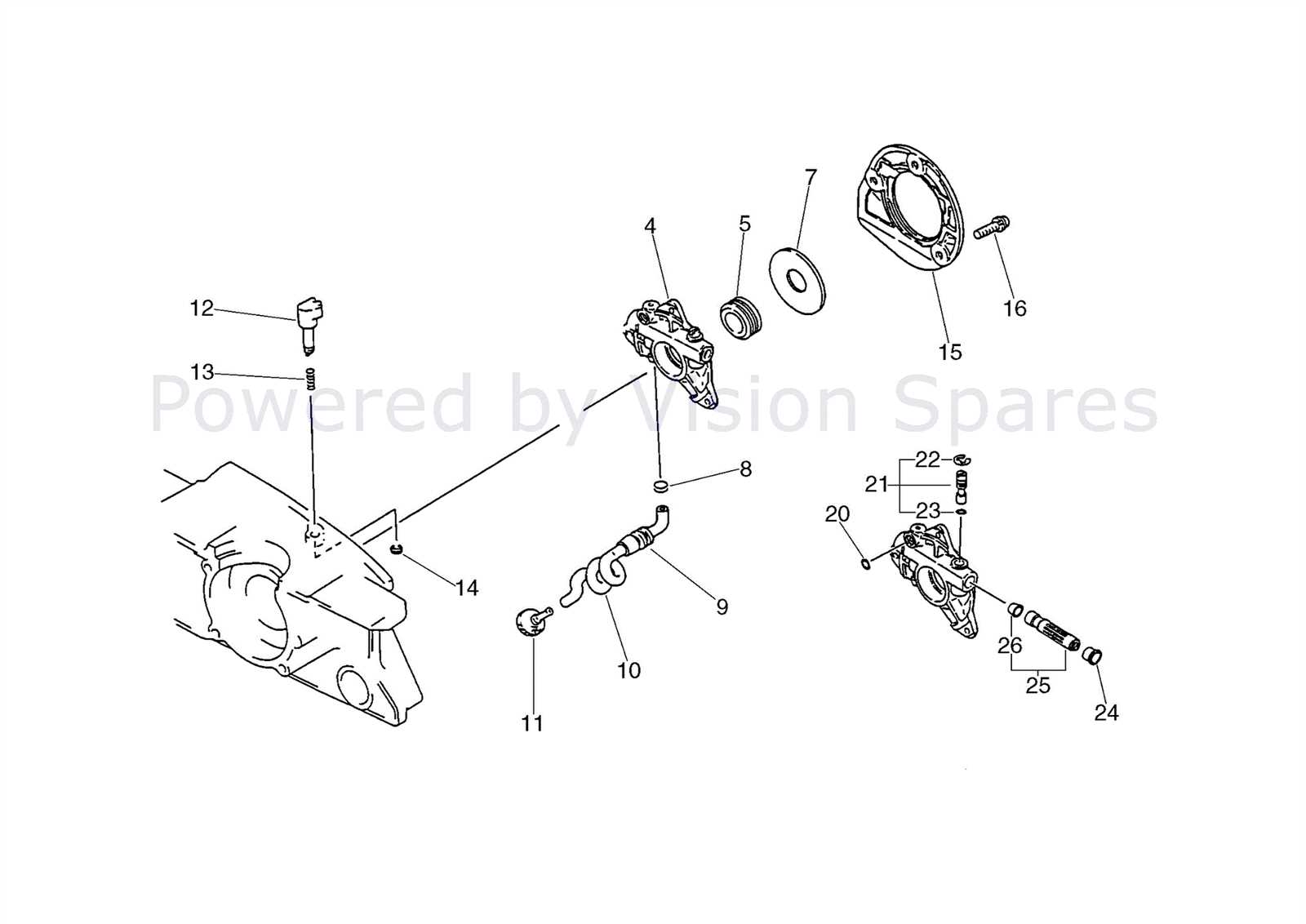

Common Repairs Using Echo Chainsaw Parts

Maintaining outdoor power tools requires addressing common issues that arise during regular use. Familiarity with the typical problems and solutions can greatly enhance your ability to make quick repairs. From minor adjustments to more complex fixes, understanding the internal components and how to replace or repair them ensures the longevity and reliability of your tool.

Replacing the Fuel System Components

Fuel-related issues are often the cause of poor performance or failure to start. Common repairs include replacing fuel lines, filters, and the carburetor. These components are crucial for ensuring proper fuel flow and combustion. Regular inspection and replacement of these parts can prevent engine stalling and inefficiency.

Fixing the Cutting Mechanism

The cutting system, including the blade and drive sprocket, is subjected to wear and tear during heavy use. Common issues with this system include dull blades, worn sprockets, or misaligned components. Regular sharpening and timely replacements can keep the cutting performance at its peak and prevent damage to the tool.