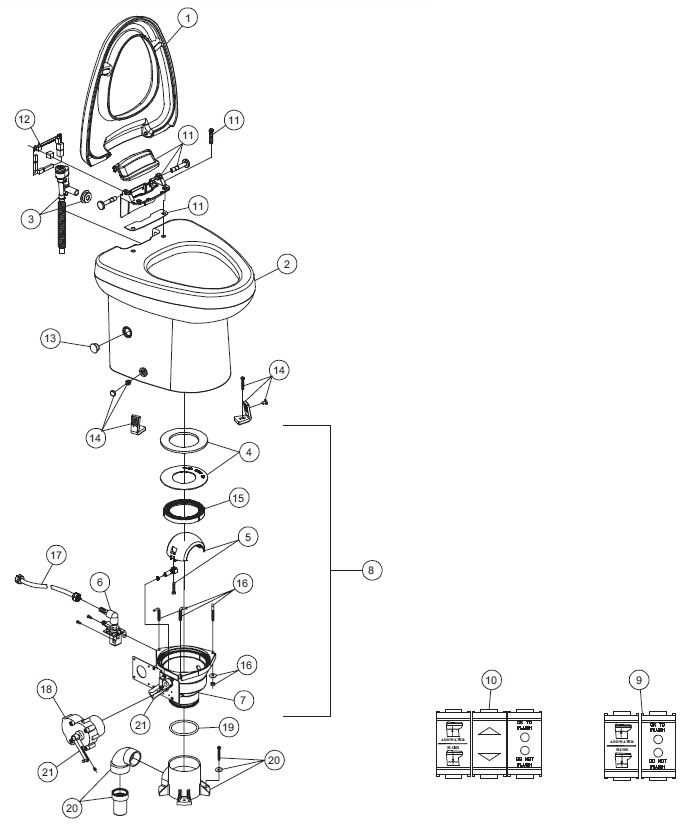

When maintaining or repairing an RV toilet, knowing the internal components and how they work together is crucial. A clear representation of the individual elements will help you identify any issues, perform necessary fixes, and ensure smooth operation. Proper knowledge can save both time and money when addressing malfunctioning parts or performing routine maintenance.

Identifying the correct components for your toilet system is the first step in effective troubleshooting. Whether you are replacing a worn-out piece or conducting a full system check, understanding where each part fits and functions is essential. The detailed layout of these components makes it easier to find the root cause of problems and select the right replacements.

Comprehending each part’s role allows for a more efficient repair process and contributes to prolonging the life of your RV toilet. With the right tools and knowledge, you can confidently address most issues without the need for costly professional help.

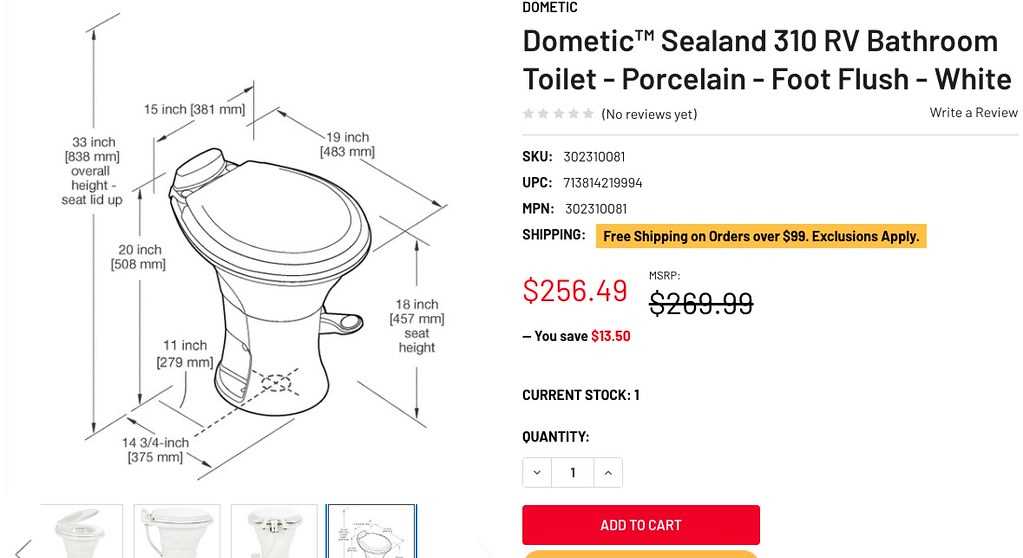

Dometic 310 Toilet Parts Overview

Understanding the different components of your RV toilet system is essential for maintaining its functionality. Each element plays a specific role, from water flow to waste disposal, ensuring the unit operates efficiently. Familiarity with these pieces will allow you to perform repairs or replacements when necessary, helping you keep your system in top condition.

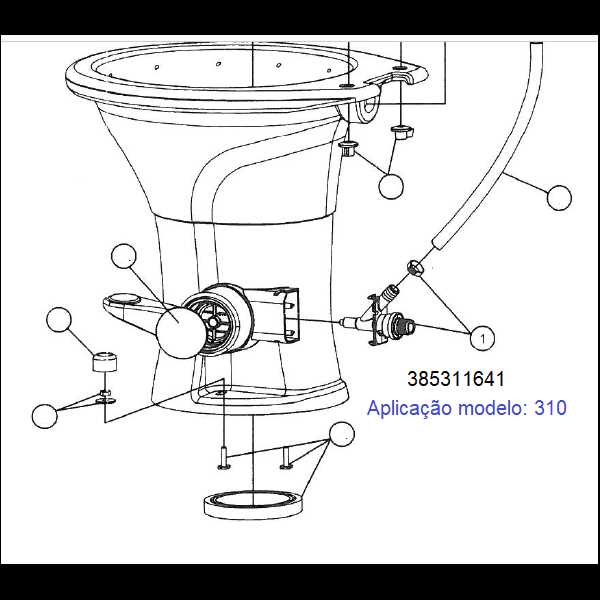

The flushing mechanism, seals, and valves are some of the most critical parts that require attention over time. Each of these components works together to control the water flow, manage waste, and prevent leaks. Knowing how they interact ensures you can identify potential issues quickly and address them before they become more serious.

Regular inspection of key elements like the pedal, tank, and waste outlet can also help prevent malfunctions. By staying proactive, you can avoid unnecessary repairs and extend the life of your toilet system. Understanding how each part functions makes it easier to troubleshoot problems effectively and keep your RV bathroom running smoothly.

Understanding the Dometic 310 Diagram

Having a visual representation of the toilet system components is crucial for efficient maintenance and troubleshooting. A detailed illustration helps you see how each element fits together and functions in the overall system. This makes it easier to identify potential issues and locate the right parts for repairs or replacements.

The schematic layout allows you to better understand the relationships between various components, such as valves, seals, and flushing mechanisms. By understanding the flow and connections, you can pinpoint where problems may arise and how to resolve them. This knowledge is invaluable when performing diagnostics or replacing worn-out elements.

Using a comprehensive diagram as a reference simplifies the process of identifying components and helps ensure that any maintenance work is done accurately. Whether you are a seasoned RV owner or a first-timer, this visual guide is an essential tool for keeping your toilet system in optimal condition.

Common Issues and Solutions for Dometic 310

Toilet systems in RVs can experience several issues over time due to wear and tear, improper use, or lack of maintenance. Identifying common problems early on can save you time and prevent more serious damage. Understanding these issues and their solutions will help you keep the unit running smoothly and avoid costly repairs.

Clogging and Blockages

One of the most frequent issues is clogging or blockages, which can prevent the toilet from flushing properly. This is usually caused by excessive waste, incorrect use of toilet paper, or foreign objects. To resolve this, it’s important to carefully inspect the system and clear any blockages in the waste outlet. Regular maintenance, such as using a tank treatment, can help minimize future clogs.

Leaking Seals and Valves

Another common problem is leaking from seals or valves, which can cause water to escape from the system and lead to unpleasant odors or potential water damage. Replacing worn-out seals or repairing faulty valves usually solves this issue. Regular checks of the system’s seals and connections will help catch these issues before they worsen.