When maintaining or repairing complex machinery, understanding how different parts fit together is essential. Knowing the layout and function of each component helps ensure proper operation and prevents potential issues. This knowledge also aids in making informed decisions when it’s time to replace or fix specific elements.

In this guide, we will explore how to interpret the schematic representations of key components in various devices. We will also highlight common issues and offer tips for efficiently replacing or upgrading parts. Whether you’re a seasoned technician or a beginner, this information will provide valuable insights to simplify your maintenance tasks.

Accurate identification and efficient repair practices are the keys to extending the lifespan of your equipment and improving its overall performance. Understanding how each element contributes to the system’s functionality is crucial for effective upkeep and troubleshooting.

Understanding Polaris P825 Parts

Knowing how each component functions and interacts within a system is crucial for effective maintenance and repair. Every machine consists of various elements, each playing a vital role in its overall operation. Understanding these parts allows you to diagnose problems accurately and perform repairs efficiently.

Key Components and Their Roles

The most important elements of a system are often the ones that control movement, power distribution, and operation. For example, motors, belts, and filters are central to keeping the machinery running smoothly. Each piece has a specific role in ensuring the device performs as expected, and identifying wear or damage early can help prevent more serious issues down the line.

Replacing and Maintaining Essential Elements

Maintaining equipment is just as important as understanding its components. Over time, certain parts will inevitably wear out and need replacing. Knowing the proper replacements and their functions helps avoid unnecessary downtime. Regular checks and timely replacements of critical components such as gears, motors, and control systems can extend the lifespan of the equipment and enhance its performance.

Proper care and accurate identification of key parts can greatly improve both the longevity and efficiency of the machinery, reducing the frequency of repairs and keeping it running smoothly for longer periods.

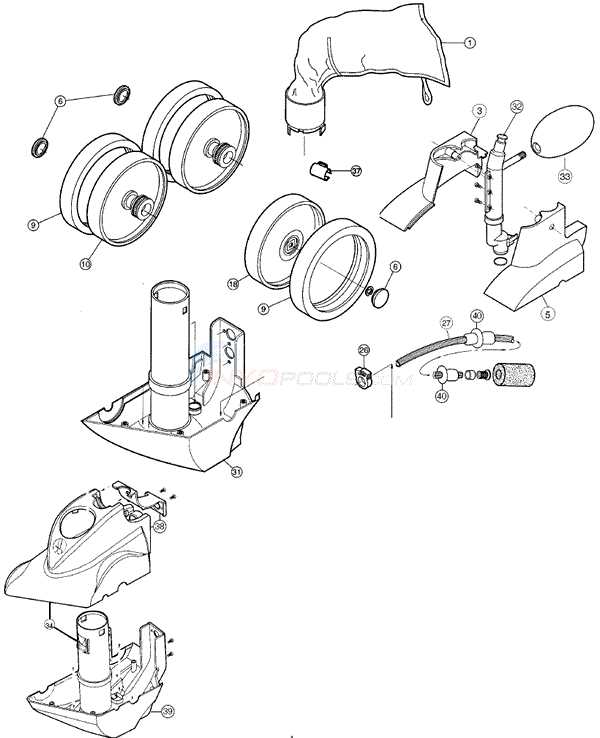

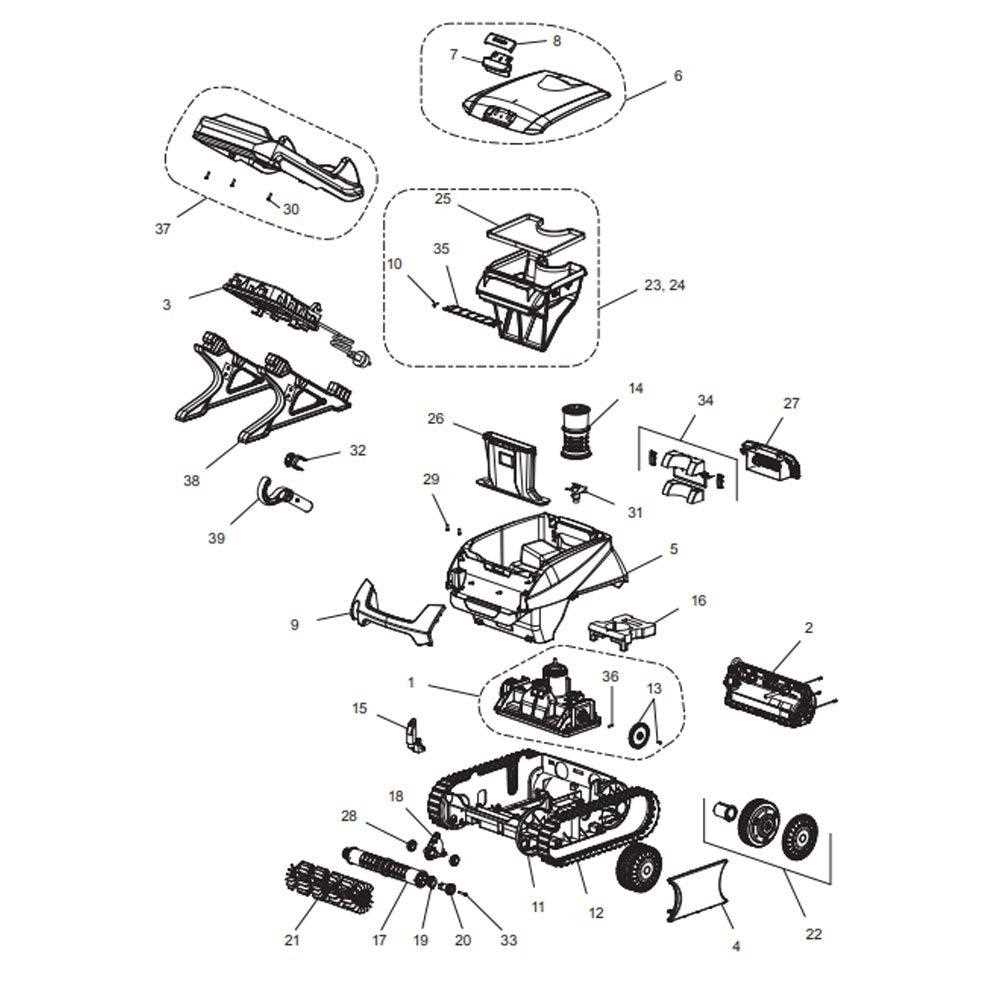

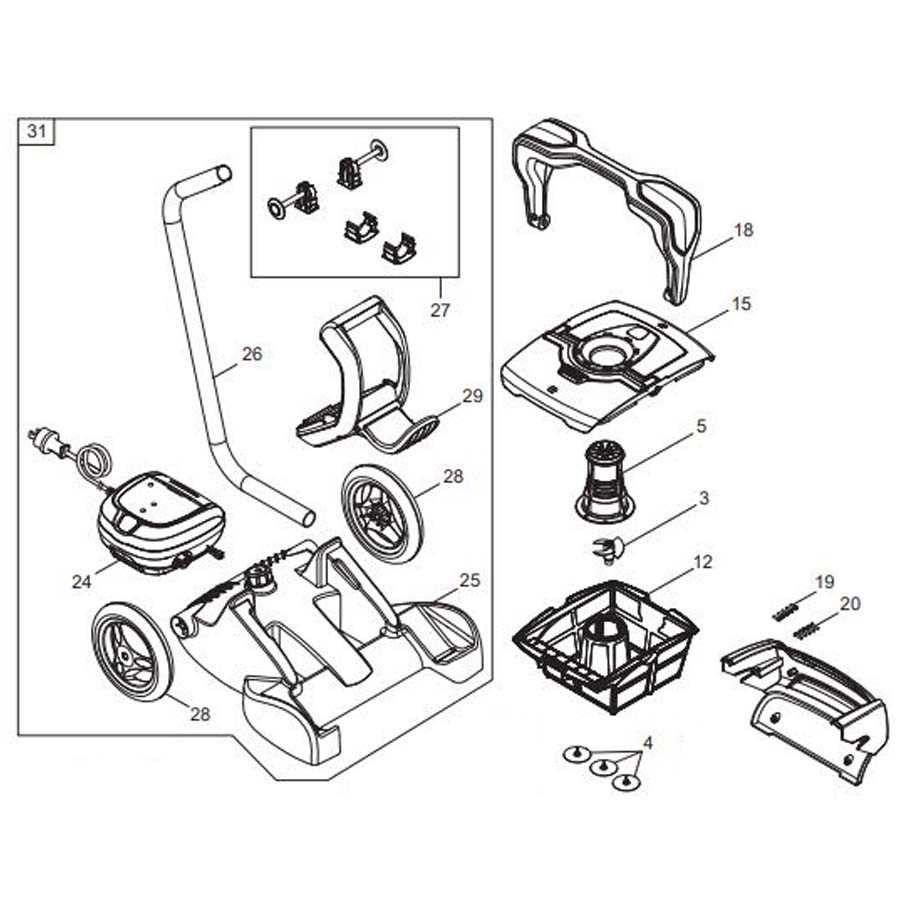

How to Read the Parts Diagram

Understanding technical schematics is essential for troubleshooting and repairing complex machinery. These visual representations provide a clear view of how different elements are arranged and connected, allowing for easier identification of components and their functions. Mastering how to read such diagrams can significantly improve your ability to perform accurate repairs and maintenance.

Identifying Key Components

Each symbol or illustration in a schematic corresponds to a specific part of the system. These illustrations are often labeled with part numbers, which correspond to detailed lists. By following these references, you can quickly locate the necessary components in a physical setup. Understanding the layout and relationships between parts is crucial for assessing how they function together.

Interpreting Connections and Functions

Diagrams also show how components are connected, whether by wires, belts, or other means. Recognizing these connections helps in understanding the flow of energy, signals, or materials throughout the system. Pay attention to arrows, lines, and labels that indicate flow or direction. This will guide you in locating any faults and determining which parts need attention or replacement.

Proficiency in reading schematics can save time and reduce errors when diagnosing issues or performing repairs. With practice, interpreting these visual guides will become a valuable skill in maintaining machinery effectively.

Common Replacement Parts for Polaris P825

Over time, certain elements of any mechanical system will naturally wear out or break. Identifying which components need to be replaced can improve performance and extend the life of the equipment. Some parts are more prone to damage and require frequent replacement due to their essential roles in the system.

Motors and Drive Belts

Motors and drive belts are often the first components to experience wear. These elements are crucial for powering movement and ensuring smooth operation. A malfunctioning motor or a worn-out belt can lead to inefficiency or complete system failure, making timely replacement essential to maintaining optimal function.

Filters and Wheels

Filters, particularly air and water filters, need to be replaced regularly to prevent clogging and ensure efficient performance. Additionally, wheels and casters are subject to wear from constant movement and contact with surfaces. Replacing these components as needed can help avoid unnecessary strain on the system and maintain smooth operation.

Regular maintenance and timely replacement of these commonly used components ensure that the equipment remains in peak condition, reducing downtime and the need for more expensive repairs.