Every tool designed for fastening requires a set of crucial elements that ensure it operates effectively. Understanding how these components work together can help users maintain, troubleshoot, and optimize their equipment. A stapling device, for instance, is made up of several key pieces that perform distinct functions, each contributing to its overall performance.

These essential components are interconnected, allowing for smooth and reliable usage. Knowing the roles of each part and how they interact can prevent frequent malfunctions and extend the tool’s lifespan. Whether you’re an experienced professional or a beginner, familiarizing yourself with the inner workings of such equipment can significantly improve its efficiency.

Understanding the Components of the Stapling Tool

Every tool built for fastening requires a combination of crucial elements that ensure its proper function. These components work together in harmony, allowing the device to perform its intended task efficiently. Familiarizing yourself with these individual parts can help you use the tool more effectively and prevent common malfunctions.

Key Elements That Ensure Functionality

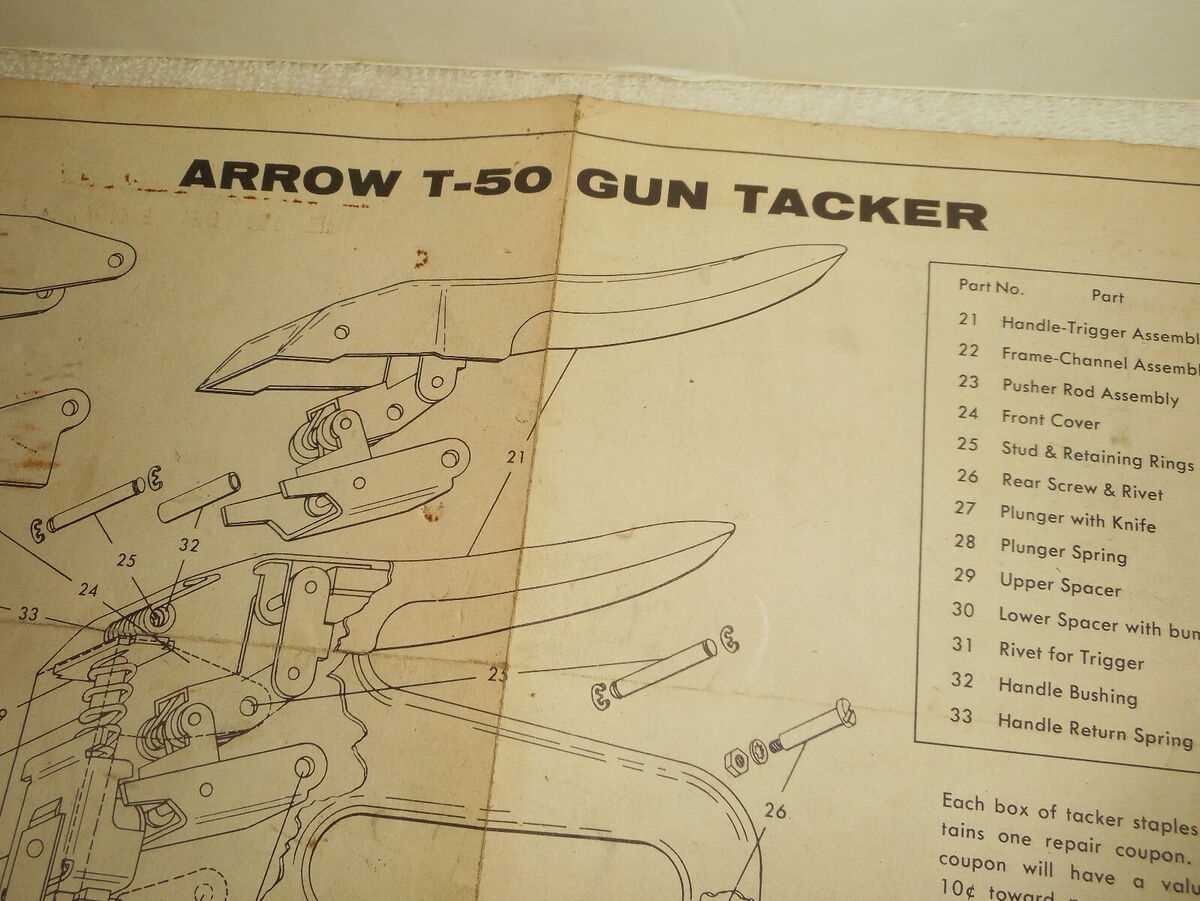

One of the most important aspects of any fastening tool is the mechanism that controls the loading and ejecting of fasteners. This system relies on springs and levers, which work together to drive the fastener into the material being worked on. Understanding how these elements interact is essential for proper tool operation and maintenance.

Identifying Wear and Tear Areas

Over time, certain components may show signs of wear, especially the moving parts. These can include the trigger mechanism or the area where fasteners are loaded. Regular inspection of these parts helps prevent malfunctions and ensures a smooth, consistent performance. Knowing which components are prone to damage can help you address issues before they affect the tool’s function.

How the Components Work Together

For any tool designed to secure fasteners, the various elements inside must function in harmony. Each part plays a distinct role, but together, they ensure that the tool operates smoothly. Understanding how these elements interact can help users achieve optimal performance and avoid potential issues.

The mechanism that controls the driving of fasteners relies on a series of connected components. Springs provide the necessary force to drive the fastener, while levers and triggers control the motion. When the trigger is pulled, the force from the spring is released, activating the driving mechanism that pushes the fastener into the material. The cooperation between these elements ensures precision and efficiency during use.

Additionally, the loading mechanism must be synchronized with the driving system to ensure that each fastener is correctly positioned before being ejected. This precise coordination prevents jams and ensures a continuous flow of work. The alignment of all these elements is crucial for the smooth operation of the tool, highlighting the importance of regular maintenance to keep everything functioning correctly.

Common Issues with Stapling Tools

Like any mechanical tool, devices designed for fastening can encounter a range of problems over time. Understanding the most common issues that arise can help users troubleshoot and maintain their equipment more effectively. By recognizing the signs early, it becomes easier to resolve problems before they lead to significant malfunctions.

Jams and Misfeeds

One of the most frequent issues is a jam or misfeed, where the fastener doesn’t load or fire correctly. This can be caused by improper loading of fasteners, or debris in the mechanism that interferes with the flow. A thorough inspection and regular cleaning can help prevent these blockages and ensure the tool operates smoothly.

Weak or Inconsistent Firing

Another common problem is inconsistent or weak firing, where the fastener is not driven into the material with enough force. This may be caused by worn springs, damaged levers, or insufficient air pressure in pneumatic models. Regular maintenance and replacing worn-out components can restore the tool’s full functionality.