When working with diesel engines, having a clear understanding of the internal components is crucial for proper maintenance and troubleshooting. The more familiar you are with each element, the easier it becomes to identify issues and ensure optimal performance.

In this guide, we will explore the layout and function of various engine components, offering insight into their roles and how they interact with each other. This knowledge will help you pinpoint areas that may require attention and provide a comprehensive overview of engine maintenance.

Knowing your engine’s design not only helps in enhancing its longevity but also enables better diagnosis of common problems. Whether you are a mechanic or a dedicated enthusiast, understanding these core components can significantly impact your repair and upkeep decisions.

Understanding the Diesel Engine

Every diesel engine operates through a series of interconnected systems and components that work together to ensure performance, efficiency, and reliability. Gaining a deep understanding of these systems helps with diagnosing issues and performing repairs effectively. By familiarizing yourself with the core structure, you can identify which parts are responsible for specific functions and how they influence overall engine health.

Engine Structure and Key Systems

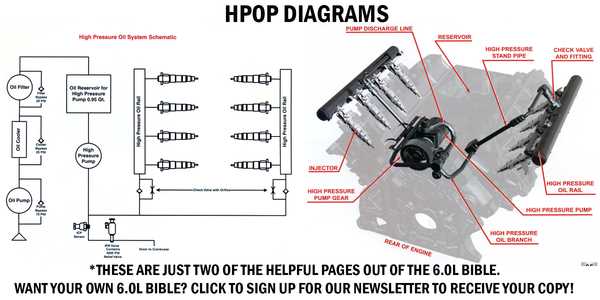

At the heart of any diesel engine is the internal combustion system, which includes key elements such as the cylinder block, pistons, and crankshaft. These parts generate power through a series of controlled explosions, which turn the crankshaft and provide rotational energy. Surrounding this system are the fuel delivery, cooling, and exhaust systems, each of which plays a vital role in maintaining smooth operation.

Performance and Maintenance Considerations

To ensure a diesel engine runs efficiently, regular maintenance and understanding of its critical components are essential. The fuel system, for example, requires proper filtration and regular inspection to avoid clogging or damage to injectors. Likewise, the cooling system needs to be checked to prevent overheating. Understanding how all these systems function together allows for timely interventions and ensures the engine continues to perform at its best.

Key Components in the Diesel Engine Layout

Every engine is made up of essential systems and individual elements that work together to deliver power and ensure reliable operation. By understanding the layout and function of each part, you can better maintain and repair the engine. Some components are crucial for power generation, while others ensure smooth operation and longevity.

Fuel and Air Intake Systems

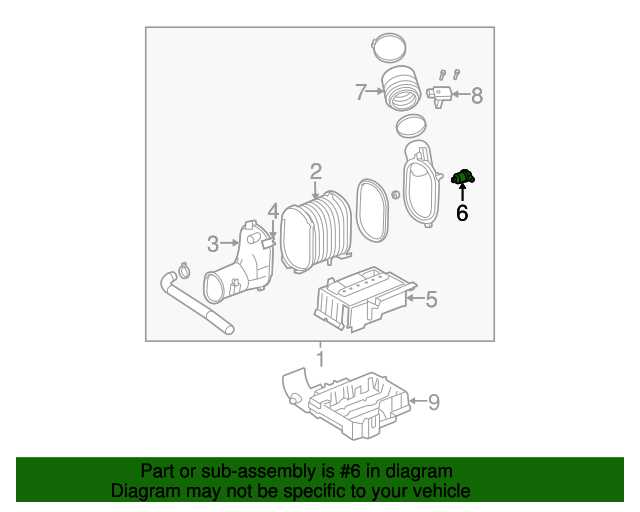

The fuel system plays a central role in the engine’s performance, ensuring proper fuel delivery to the combustion chamber. This system includes the fuel pump, fuel injectors, and filters. The air intake system, on the other hand, is responsible for providing clean air to the engine, and includes the air filter, intake manifold, and turbocharger. Both systems must be maintained properly to avoid performance issues and inefficiencies.

Cooling and Exhaust Systems

The cooling system is vital for regulating the engine’s temperature, preventing overheating, and ensuring the engine operates within the optimal temperature range. Key components include the radiator, thermostat, and coolant lines. Meanwhile, the exhaust system ensures that gases produced during combustion are efficiently expelled from the engine, helping maintain performance and reduce emissions. Regular inspection of both systems is necessary to avoid costly repairs and engine damage.

Common Issues and Repairs for Diesel Engines

Like all complex machines, diesel engines can experience a variety of issues over time. Understanding the most common problems that arise and knowing how to address them can save time and money. From fuel delivery issues to cooling system failures, these engines require regular attention to maintain their reliability and performance.

One of the most frequent issues involves the fuel system. Over time, fuel injectors may become clogged or damaged, leading to poor fuel delivery and reduced engine efficiency. Replacing or cleaning injectors and ensuring proper fuel filtration can resolve these problems and restore optimal performance.

Another common problem is related to the engine’s cooling system. A faulty radiator, thermostat, or damaged coolant hoses can cause the engine to overheat. This not only affects performance but can also lead to severe engine damage if left unchecked. Regular inspection and prompt repair of any cooling components can prevent these issues from escalating.