When maintaining complex machinery, understanding the structure and individual elements is essential for efficient operation. A detailed overview of the various components helps users identify the necessary parts for repair, replacement, or upgrades. This guide aims to offer clear insights into how these mechanisms are assembled and how each element functions within the system.

Mechanical systems can be intricate, and even minor issues in a specific area can impact overall performance. By familiarizing yourself with the key components and their functions, you will be better equipped to handle maintenance and troubleshooting tasks. Accurate identification of each unit is crucial in ensuring the longevity and optimal performance of the equipment.

In the following sections, we will explore the detailed breakdown of the machinery’s internal systems. Whether you’re performing regular checks or addressing specific malfunctions, understanding how to navigate the system’s framework is vital for effective management and troubleshooting.

Understanding New Holland 1411 Components

To ensure optimal functionality, it is important to grasp the structure and interrelationship of the various mechanical elements in the system. Each component has a specific role that contributes to the overall performance of the machine. Understanding how each part works within the system allows for better troubleshooting and maintenance.

The system consists of several key units, each with its own function. Major assemblies such as the drive, cutting mechanism, and hydraulic components are interconnected, and any malfunction in one area can influence the rest of the system. Recognizing the function of each assembly helps prevent unnecessary downtime and ensures a smooth workflow.

By familiarizing yourself with the individual components and their placement, you can identify potential issues before they escalate. Regular checks and replacements of essential elements are crucial for maintaining the longevity of the equipment. This section will guide you through the main parts and their significance in the machinery’s overall operation.

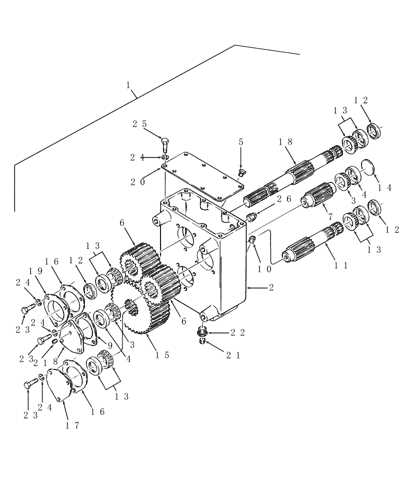

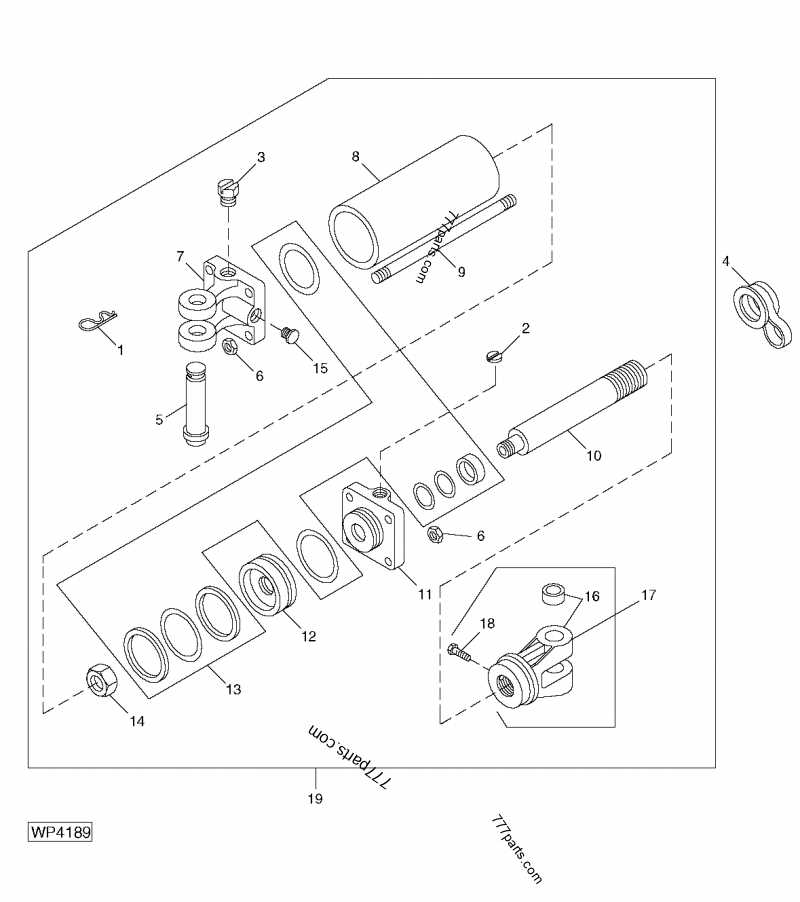

How to Read the Parts Diagram

Understanding the layout of the system’s internal structure is crucial for effective maintenance. A visual representation allows users to identify components and their relationships within the assembly. Knowing how to interpret this illustration simplifies troubleshooting and part replacement.

The key to reading such a schematic lies in recognizing the symbols and labels associated with each element. These symbols typically represent mechanical components, such as gears, levers, and hydraulic systems. Each part is usually numbered or labeled, making it easier to locate and reference them for repair or servicing.

By carefully studying the representation, users can pinpoint the location of each unit within the machine. This knowledge is invaluable when dealing with specific issues or planning maintenance tasks. Proper interpretation of the schematic is an essential skill for anyone managing or servicing the equipment.

Common Issues and Solutions for New Holland 1411

Like any complex machinery, the system can experience a range of common problems that affect its performance. Recognizing these issues early on can prevent more severe damage and costly repairs. This section will explore some of the most frequent malfunctions and offer practical solutions to address them.

Hydraulic System Malfunctions

One of the most common issues in such equipment is related to the hydraulic system, often caused by leaks or worn-out seals. These problems can lead to a loss of pressure, affecting the overall efficiency of the machine. Regular inspection of the hydraulic lines and timely replacement of seals and hoses can help avoid system failure and keep everything running smoothly.

Drive Belt Wear

Another typical issue is the wear and tear of the drive belts, which can result in slippage or complete failure. This often occurs when belts are improperly tensioned or when they have been in use for extended periods. Ensuring proper tension and replacing belts at the recommended intervals will prevent disruptions in operation and extend the lifespan of the components.