When it comes to maintaining your lawn equipment, understanding how each part functions is essential for efficient operation. A clear overview of the different components allows users to perform basic repairs and avoid unnecessary breakdowns.

Identifying and replacing damaged or worn-out elements can extend the life of your mower. By recognizing key sections, you can also ensure proper maintenance, ensuring smooth operation and preventing costly repairs.

In this guide, we’ll explore the layout and functionality of each crucial element, helping you gain confidence in handling necessary fixes. Whether you’re troubleshooting common issues or simply looking to improve performance, a solid understanding of the machine’s internals is a must.

Understanding the Lawn Mower Components

In any lawnmower, several critical elements work together to ensure efficient performance. By familiarizing yourself with the key components, you can perform maintenance tasks more effectively and identify potential issues before they escalate.

Engine and Power System

The engine is the heart of the mower, providing the power necessary to operate the cutting system. It is connected to various components like the air filter, spark plug, and fuel system. Regular checks and maintenance of these parts help avoid performance drops and potential failures.

Cutting Mechanism and Blade Assembly

The blade assembly is responsible for achieving the desired cut. It works in tandem with the motor, ensuring that the lawn is trimmed evenly. Proper care, including blade sharpening and alignment, is essential for achieving a clean and efficient cut. Regular inspection of the blade attachment and motor connection ensures smooth operation.

How to Read the Parts Diagram

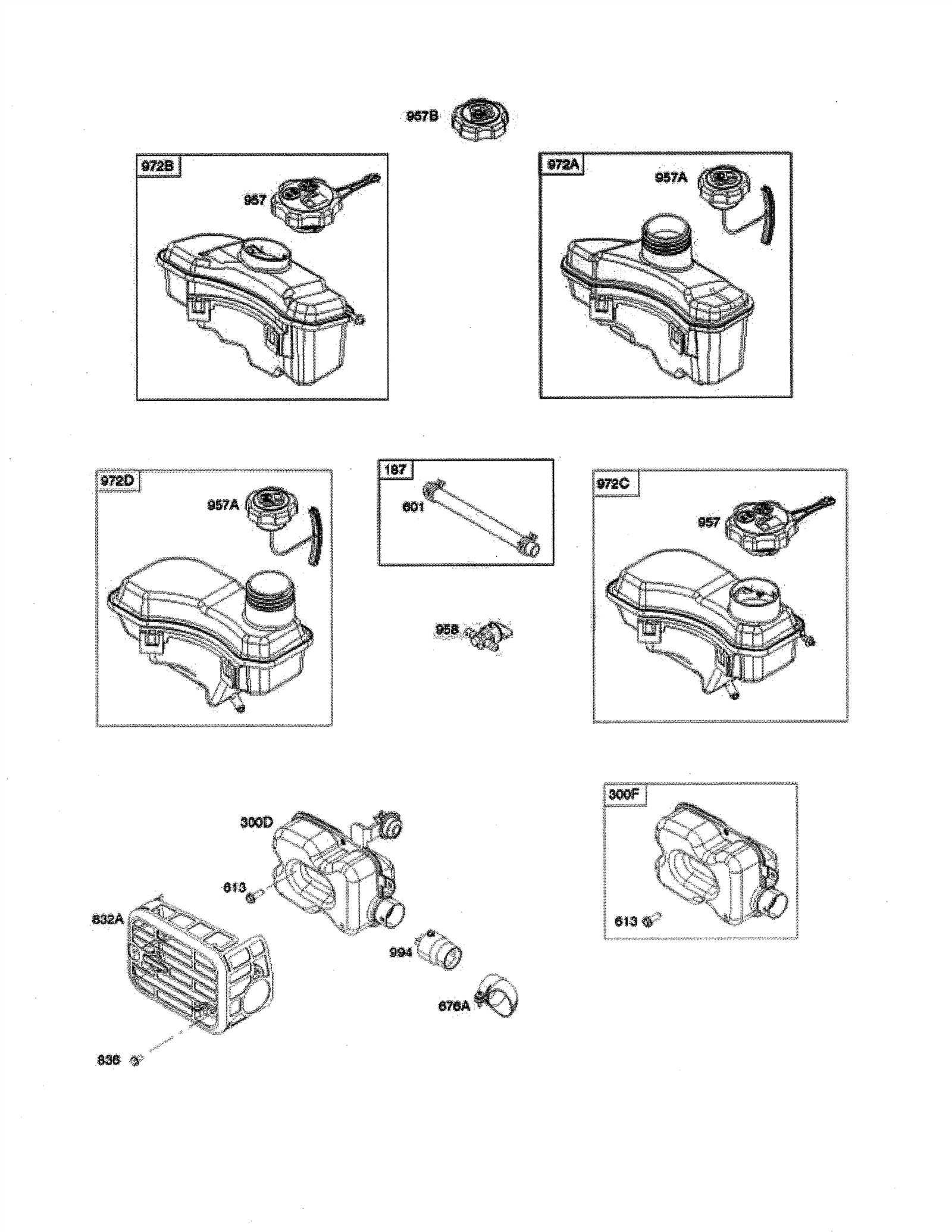

Understanding the layout of your lawnmower’s components is essential when it comes to repair and maintenance. A detailed representation provides an easy reference for locating parts, their connections, and how they function together to ensure the machine runs smoothly.

Identifying Key Components

The first step in reading a schematic representation is recognizing the various components. Each part is usually labeled with a number or letter, which corresponds to a detailed list, helping you identify specific items such as the engine, blades, and control systems. Being able to pinpoint these parts quickly allows you to act efficiently when performing repairs.

Understanding Connections and Assembly

Another key feature of these illustrations is the depiction of how the parts are connected. This allows you to understand the flow of operation and how replacing or adjusting one part may affect others. By following the lines or arrows, you can trace the connections, ensuring you are working with the correct pieces during assembly or disassembly.

Identifying Key Parts for Repair

When facing a malfunction with your mower, knowing which components require attention is crucial. Identifying the right pieces helps you focus your efforts on repairing or replacing only the necessary elements, saving time and avoiding unnecessary work.

The following are some of the most common parts that often require repair or replacement:

- Engine components: These include the spark plug, air filter, and carburetor. Check for clogging or wear and replace if necessary.

- Blades: Inspect the cutting blades for damage or dullness. Sharpen or replace them if they show signs of wear.

- Wheels and axles: Look for any damage or misalignment that could affect maneuverability.

- Fuel system: Ensure the fuel lines and tank are free from leaks or blockages.

- Drive belts: Inspect for any cracks or wear. A damaged belt can impact the mower’s ability to function properly.

By regularly checking these components, you can ensure that your mower continues to operate effectively and avoid more significant issues in the future.

Maintenance Tips for Lawn Mower

Proper upkeep of your lawnmower is essential to prolonging its life and ensuring peak performance. Regular maintenance can prevent breakdowns, improve efficiency, and help you avoid costly repairs. Following a consistent maintenance routine will keep your machine running smoothly throughout its use.

Keep the Engine Clean: Ensure the engine area remains free from dirt and debris. Regular cleaning helps prevent clogs and ensures proper ventilation, reducing the strain on the engine during operation.

Change the Oil: Regularly check and replace the oil according to the manufacturer’s recommendations. Clean oil ensures the engine runs smoothly, preventing overheating and mechanical wear.

Sharpen the Blades: Dull blades not only reduce cutting efficiency but can also stress the engine. Sharpen the blades periodically or replace them if they become too worn. Ensure the blades are properly balanced to avoid uneven cutting.

Inspect the Fuel System: Clean the fuel filter regularly to prevent clogging and ensure proper fuel flow. Also, replace any worn fuel lines to avoid leaks and maintain efficient fuel delivery.

Check Tire Pressure: Ensure that the tires are inflated to the recommended pressure. Proper tire inflation helps maintain the mower’s stability and maneuverability while preventing uneven wear.

By following these simple maintenance tips, you can ensure the longevity and reliability of your equipment, ensuring it performs well season after season.

Common Issues and Part Replacements

Over time, various issues can arise with your mower, many of which can be easily fixed by replacing worn or damaged components. Identifying these common problems early can prevent further damage and help maintain the mower’s efficiency. Understanding what parts may need to be replaced will make the repair process smoother and more cost-effective.

Engine Failing to Start: This is a common issue, often caused by a clogged spark plug or an old, dirty air filter. Replacing the spark plug and cleaning or replacing the air filter will usually resolve this problem.

Uneven Cutting: If the mower is not cutting evenly, the blades may be dull or damaged. Sharpening or replacing the blades can restore proper cutting performance and prevent strain on the engine.

Loss of Power: A decrease in engine power can be caused by a clogged fuel filter or a blocked carburetor. Replacing the fuel filter and cleaning the carburetor should restore power and efficiency.

Excessive Vibration: Vibrations can occur due to loose or unbalanced blades. Ensuring the blades are properly tightened and balanced will reduce vibration and improve cutting performance.

Leaking Fuel: Fuel leaks often result from cracked or worn fuel lines. Replacing the damaged fuel lines will prevent leaks and ensure safe operation of your mower.

By addressing these common issues and replacing the faulty components, you can maintain your mower’s functionality and extend its lifespan. Regular checks will help you catch problems early, saving time and money in the long run.