When it comes to lawn care, knowing the inner workings of your machine is crucial for maintaining its performance. Each piece of equipment has a unique structure, with different elements working together to ensure smooth operation. Understanding how these elements interact can help you troubleshoot issues and perform necessary maintenance efficiently.

In this guide, we’ll explore the essential components of a commercial mower, focusing on how each part contributes to the overall functionality. By breaking down the main sections, you’ll be able to identify specific areas for upkeep and repair. This knowledge will not only extend the life of your equipment but also improve its performance over time.

Having a clear understanding of each segment is key to ensuring your machine operates at its best. Whether you’re a professional landscaper or a homeowner, proper care can prevent major breakdowns and costly repairs. Let’s dive into the details and discover what makes this essential tool work so effectively.

Kubota ZD21 Deck Components Breakdown

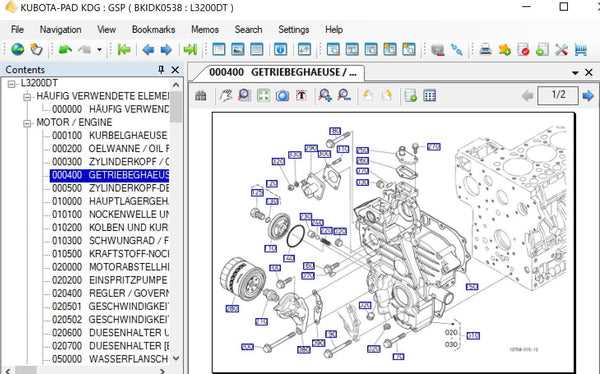

Every mower consists of a variety of essential elements that work together to ensure its optimal performance. Understanding each individual section is vital for proper maintenance and repair. These components are designed to work in harmony, with each part playing a specific role in the overall function of the machine.

The key components of this equipment are carefully crafted to withstand the stresses of regular use. From the main cutting system to the drive mechanisms, each part contributes to efficient operation. By familiarizing yourself with these critical sections, you can better manage upkeep tasks and prevent unnecessary breakdowns.

Focus should be placed on understanding the relationship between the various mechanisms. This knowledge not only aids in identifying potential issues but also helps in replacing or repairing individual parts when necessary. Proper care and attention to these details will ensure the longevity of your equipment.

Understanding the Kubota ZD21 Deck Assembly

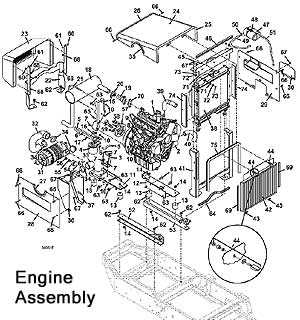

The assembly of a mower is a complex system of interconnected elements, each designed to fulfill a specific function. When you understand how these components fit together and interact, it becomes easier to troubleshoot, maintain, and optimize the performance of the entire machine. The assembly’s design ensures smooth operation by balancing power, precision, and durability in every part.

Main Components of the Assembly

The main section of the machine typically includes the drive system, cutting blades, and support structures. These parts work in unison to deliver efficient cutting and handling. Each element is engineered to endure the constant motion and friction that comes with regular use, ensuring that the mower performs at its peak for an extended period.

How the Assembly Functions Together

When the equipment is in motion, the power generated by the engine is transferred to the various components through a series of belts and pulleys. This system drives the blades, allowing them to cut the grass with precision. Understanding this flow of energy is essential for maintaining the machine’s efficiency, as any disruption in this process can lead to performance issues.

How to Maintain Kubota ZD21 Deck Parts

Proper maintenance is key to ensuring that your equipment continues to perform at its best. Regular inspection and upkeep of each component are necessary to prevent wear and tear from compromising its functionality. By staying on top of these tasks, you can avoid costly repairs and keep the machine running smoothly for years.

Start by regularly cleaning the various elements of the system, as debris can accumulate and cause friction or blockages. Check the drive components, including belts and pulleys, to ensure they are properly tensioned and in good condition. Replace any worn or damaged parts promptly to maintain optimal performance.

In addition to cleaning and inspecting, lubricating moving parts is essential. Apply the appropriate lubricants to ensure smooth motion and reduce the risk of mechanical failure. Finally, always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures to keep your machine in peak condition.