In any complex mechanical system, understanding the layout and structure of its components is essential for both troubleshooting and efficient maintenance. By familiarizing yourself with the individual elements, you can ensure that the system operates smoothly and address any issues that may arise.

Recognizing each element’s role within the machine is crucial for proper operation and longevity. A clear understanding of how each part interacts will help prevent unnecessary wear and optimize performance.

Proper analysis of the system’s construction can also lead to faster repairs and a more accurate diagnosis of potential malfunctions. With a detailed overview, maintaining these machines becomes more manageable and effective.

Understanding the FMC Sidewinder Components

When dealing with complex machinery, recognizing the various components and their functions is critical for both operation and troubleshooting. Each element of the system plays a vital role in ensuring smooth performance, and knowing how they interact helps avoid malfunctions and inefficiencies. Understanding these elements allows for easier maintenance and quicker resolution of any issues that arise.

The machine is made up of numerous parts, each designed to perform a specific function. These components work together to ensure that the system operates efficiently, and recognizing their individual roles helps in diagnostics and repairs.

- Drive Mechanism: This is responsible for the motion and power transmission throughout the system. Proper functioning of this part is essential for overall performance.

- Control System: The control system allows the operator to manage the machine’s settings and responses, making it a key element for efficient use.

- Structural Components: These are the framework elements that provide the necessary support and stability for the machine, ensuring its durability.

- Sensor Units: Sensors monitor the machine’s performance and provide feedback that helps in maintaining optimal operation.

By familiarizing yourself with the role of each part, you can prevent common issues and improve the overall functionality of the equipment. Moreover, knowing how the components are arranged and connected simplifies troubleshooting and repairs when needed.

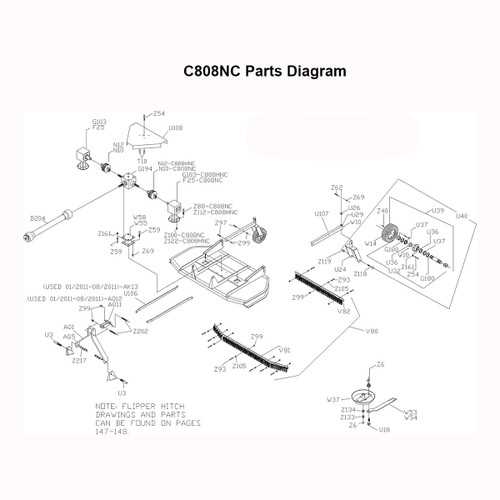

How to Interpret the Parts Diagram

Understanding the layout of a mechanical system is essential for proper maintenance and repairs. Interpreting the visual representation of the machine’s structure allows you to quickly identify the components and their respective functions. A well-detailed illustration not only shows the parts but also highlights how they are interconnected, offering a clear view of the machine’s working mechanism.

To effectively read such a visual guide, start by focusing on the overall structure. Look for key indicators, such as labels, numbers, and color codes, which provide important information about each part. Pay attention to the way the components are arranged, as this will show how they interact and contribute to the system’s operation.

Additionally, understanding the symbol conventions used in these illustrations will help you make sense of the different elements. For example, arrows may indicate the direction of movement, while dotted lines could represent hidden or internal connections. By familiarizing yourself with these conventions, interpreting the diagram becomes a much easier task, facilitating quick problem identification and resolution.

Essential Maintenance Tips for the Machine

Proper upkeep is crucial for extending the lifespan and efficiency of any complex mechanical system. Regular maintenance ensures smooth operation, reduces the risk of unexpected breakdowns, and prevents costly repairs. By following a routine maintenance schedule and addressing small issues early, you can keep the system running at optimal performance levels.

Regular Inspections

One of the most important steps in maintaining any machine is conducting frequent inspections. Check all components for signs of wear, damage, or buildup. Pay particular attention to moving parts, as these are most susceptible to wear over time. Look for any unusual noises or vibrations, which could indicate underlying issues. Promptly addressing these issues will help prevent larger, more costly problems down the line.

Lubrication and Cleaning

Keeping the system clean and properly lubricated is essential for maintaining its smooth operation. Lubricate all moving parts according to the manufacturer’s guidelines to reduce friction and prevent damage. Regularly clean the machine to remove dust, dirt, and debris that can affect performance. Make sure to use appropriate cleaning agents that will not harm the system’s materials or components.

By following these essential maintenance tips, you can ensure the longevity and reliability of your machinery, keeping it in top working condition for years to come.