Maintaining and repairing outdoor machinery can be a challenging task, especially without a clear understanding of how its individual components work together. Knowing the structure of your equipment is essential for effective upkeep, ensuring long-term performance and preventing breakdowns. A well-organized visual reference can help you identify parts and address issues quickly.

Whether you’re a professional technician or a DIY enthusiast, having access to detailed schematics is invaluable. These diagrams serve as essential tools for identifying and replacing specific components. With the right information, you’ll save time, reduce the risk of errors, and improve your equipment’s longevity.

In this article, we will walk you through the key elements of a standard layout, offering insight into how various sections of your machine interconnect. Understanding these relationships will simplify troubleshooting and help you make informed decisions when replacing worn-out parts.

Understanding Toro 20332 Parts Diagram

Knowing how to interpret the visual layout of lawn equipment is a crucial skill for maintenance and repair tasks. These detailed illustrations provide an organized view of the machinery’s internal structure, helping users to understand how each component fits together. Whether for troubleshooting or replacing faulty elements, having a clear reference guide simplifies the entire process.

How Diagrams Help with Maintenance

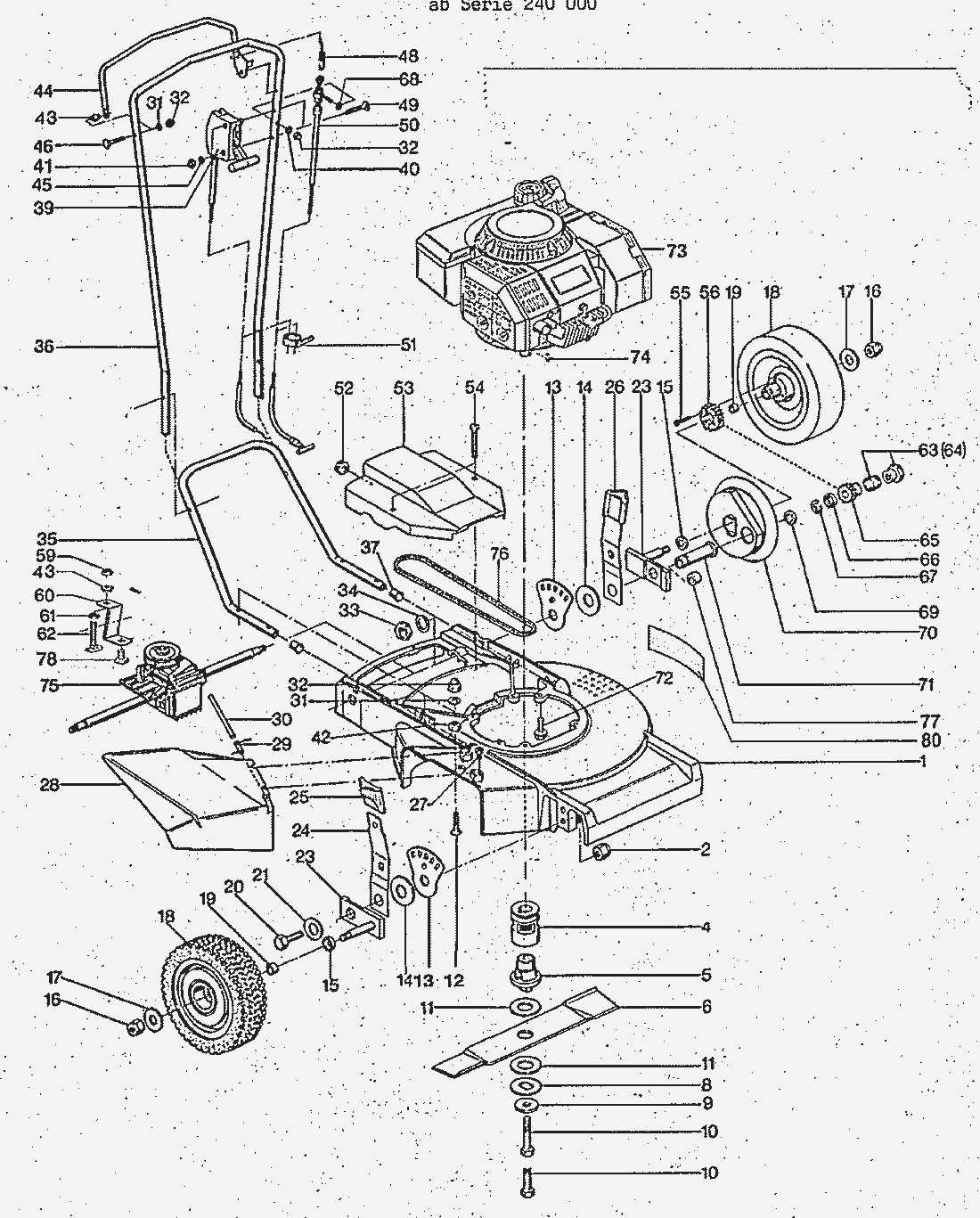

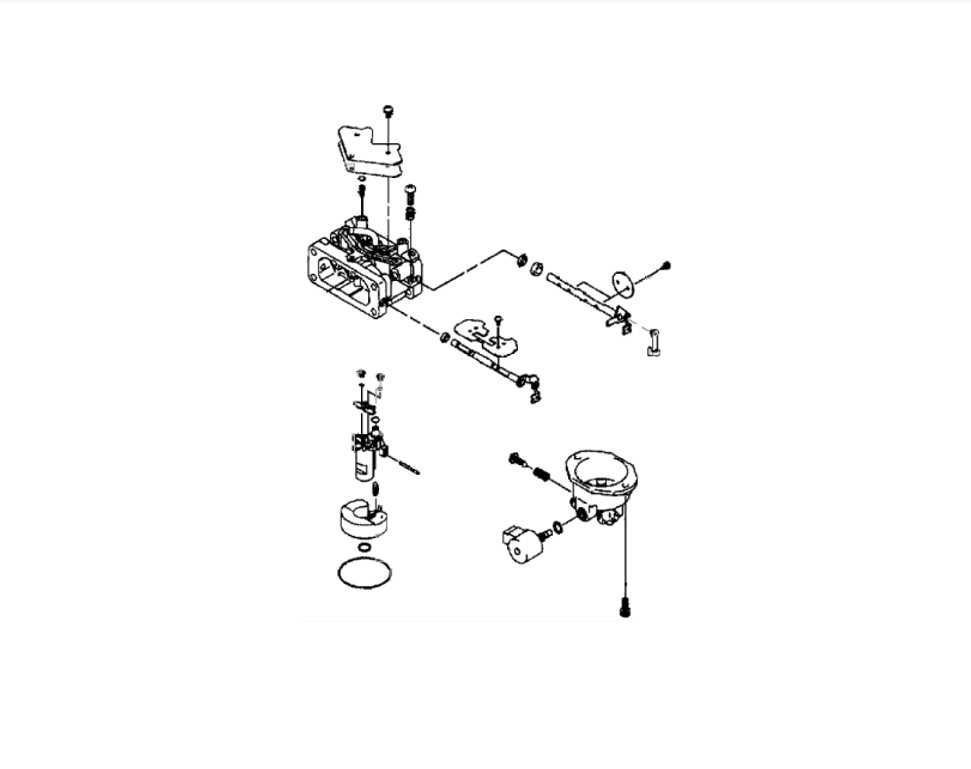

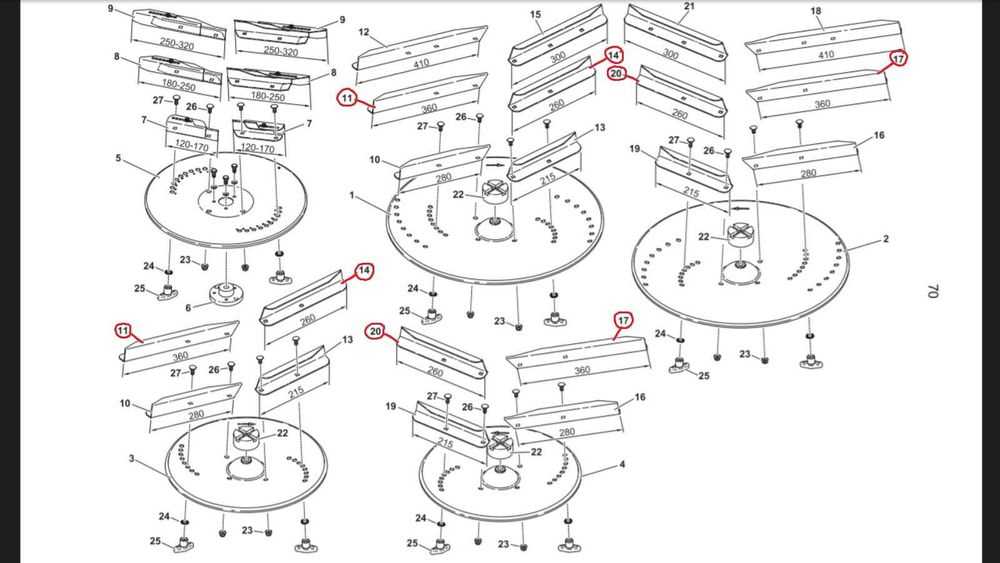

By using a detailed schematic, you can quickly locate and identify specific sections of your equipment that may need attention. The visual representation breaks down complex mechanisms into manageable parts, making it easier to pinpoint issues and proceed with repairs. Understanding the function of each part can prevent unnecessary mistakes and ensure that all components are properly aligned during reassembly.

Common Issues Addressed with Schematics

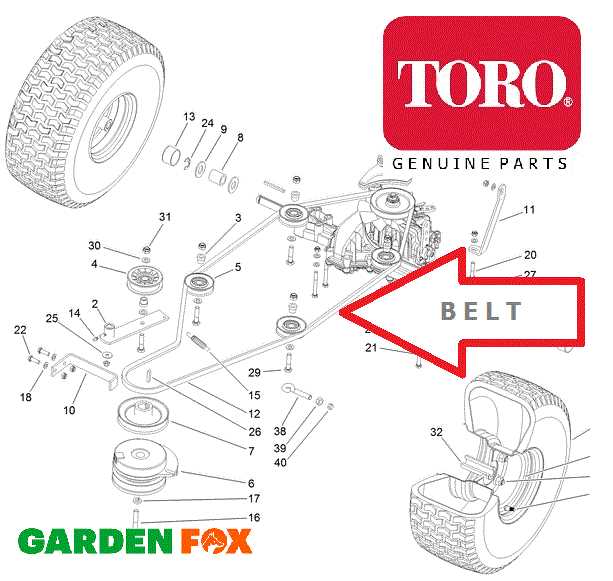

Many common issues, such as malfunctioning motors or worn-out belts, can be identified more effectively through a detailed layout. These diagrams help you isolate problem areas, enabling precise adjustments or replacements. With the proper guide, diagnosing and fixing issues becomes more efficient, reducing downtime and extending the life of the machine.

How to Identify Toro 20332 Components

Identifying individual elements of your lawn equipment is the first step towards effective maintenance and repair. Understanding the function of each part allows you to recognize when something is worn or malfunctioning. By following a structured approach, you can easily match components to their respective functions, ensuring that you address only the necessary parts during repairs.

Locating and Understanding Key Parts

Start by locating the main sections of your machine. Key parts such as the engine, drive belt, and wheels often have distinctive shapes or markings that make them easier to spot. Once you identify these sections, cross-reference them with the machine’s visual guide to get a clearer idea of their role. Each part is typically connected to others in a specific way, and understanding these connections helps in determining the root cause of an issue.

Using References to Match Components

When unsure of a specific component, use the reference material to match it with the corresponding image. Pay attention to the size, shape, and placement of each element within the machinery layout. Detailed diagrams usually offer a clear distinction between similar parts, helping you quickly identify and replace damaged or worn components. Proper identification ensures that you are always working with the right part, preventing errors and minimizing downtime.

Step-by-Step Guide for Toro 20332 Repairs

Performing repairs on lawn machinery can seem intimidating, but following a systematic process makes the task manageable. With the right approach, you can troubleshoot problems and replace faulty components without professional assistance. This guide will walk you through the essential steps for addressing common issues and performing maintenance on your equipment efficiently.

Preparing for the Repair

Before starting any repair, ensure the equipment is turned off and disconnected from any power source. Gather all necessary tools, including wrenches, screwdrivers, and replacement parts. Having everything on hand will streamline the repair process and prevent delays. Additionally, reviewing the machinery’s layout beforehand helps you understand what you’re working with and where potential issues may lie.

Step-by-Step Repair Process

Begin by diagnosing the issue. Identify any visible signs of wear or malfunction, such as frayed belts or broken parts. Once you’ve pinpointed the faulty component, consult the visual guide to determine how to access and replace it. Carefully remove the defective part, taking note of how it is connected to the surrounding components. Install the new part, ensuring it is securely fastened. Afterward, reassemble the machinery and test it to ensure proper function.