Maintaining a tractor in optimal condition requires a deep understanding of its individual components and how they interact. Whether you are a professional mechanic or a tractor owner, having access to an organized and detailed reference guide can save time and reduce mistakes during repairs. Knowing the essential parts of the machinery and how to navigate them is crucial for effective troubleshooting and upkeep.

Detailed guides that break down the machinery into smaller, manageable sections offer invaluable assistance. By studying these references, you can quickly identify the right pieces when performing maintenance or replacing worn-out components. This knowledge also helps in understanding the assembly and disassembly process, ensuring smoother and more efficient work.

Regular inspections and timely interventions are key to extending the life of your equipment. The more familiar you are with the individual sections and their functions, the better equipped you will be to handle any mechanical issue that arises.

Understanding the Tractor Components

To effectively maintain and repair any agricultural vehicle, it’s essential to gain a clear understanding of its individual elements. Each part has a specific function that contributes to the overall performance of the machine. Familiarizing yourself with these components allows for more efficient problem-solving and ensures that you can address issues as they arise. Recognizing how different sections of the vehicle work together can also help prevent unnecessary repairs and downtime.

Main Sections of the Vehicle

The vehicle can be broken down into several core areas, each crucial to its operation. These include:

- Engine: The heart of the machine, responsible for providing the necessary power for all movements.

- Transmission: This system helps in transferring the engine’s power to the wheels, allowing the tractor to move.

- Hydraulics: Controls lifting mechanisms, implements, and other essential functions that require force.

- Steering and Suspension: Responsible for maneuvering and ensuring stability on uneven terrain.

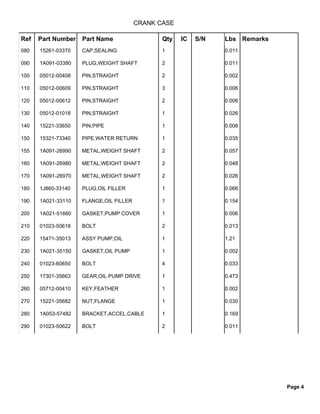

Identifying Key Components for Maintenance

When conducting maintenance or repair work, identifying the exact components is the first step to resolving any issues. Using a reference guide can help you locate:

- Wearable components like filters, belts, and hoses.

- Electrical systems including fuses and wiring connections.

- Critical moving parts like bearings, shafts, and gears.

With a thorough understanding of these components, you can perform effective troubleshooting and ensure your equipment remains operational for a longer period of time.

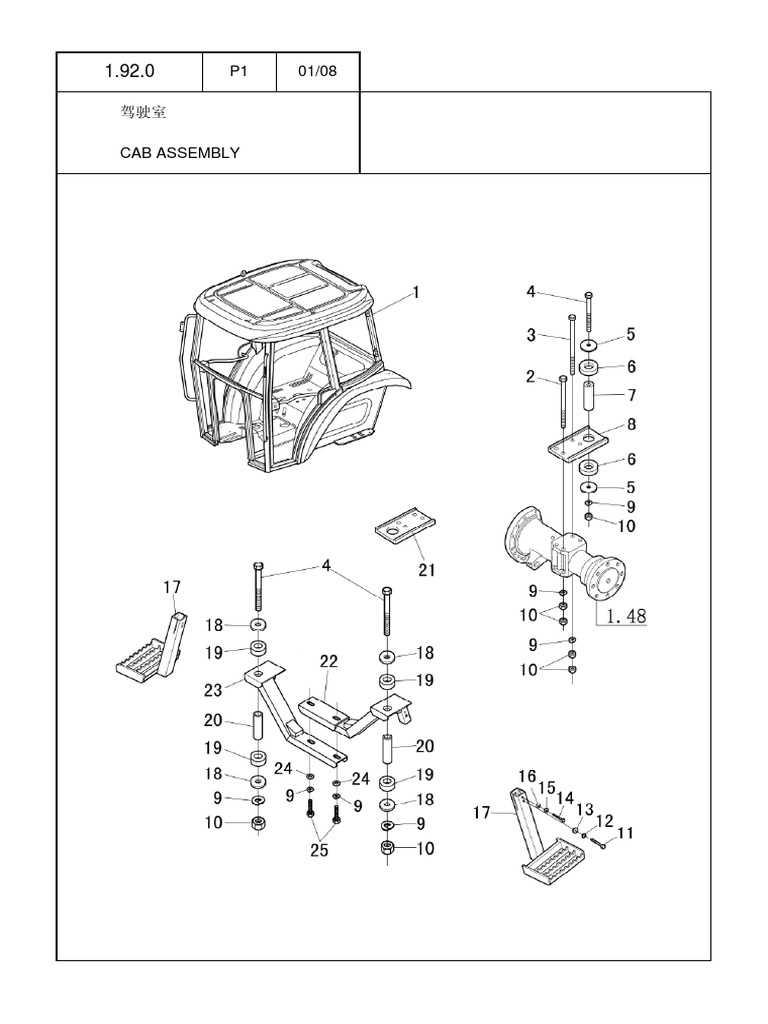

How to Use the Diagram Effectively

Accessing a detailed visual reference for your machine’s components is an essential step in performing accurate repairs and maintenance. By understanding how to navigate this guide, you can quickly locate specific sections and identify the parts you need to inspect or replace. Proper use of this tool minimizes errors and ensures that each task is completed with efficiency and precision.

To use the reference guide effectively, start by familiarizing yourself with the overall structure of the machinery. Understanding the categories within the diagram will allow you to focus on the most relevant sections for your current needs. Once you’ve identified the area of interest, use the visual cues to pinpoint individual components and their respective numbers for easy ordering and replacement.

Another key aspect of using the diagram is cross-referencing it with your machine’s manual. This combination helps ensure that you have all the information needed to complete any task. If you come across any unclear sections, searching for additional resources or consulting with a professional may also be beneficial for accuracy.

Common Issues and Repairs for the Tractor

Like any heavy machinery, tractors often experience specific problems that require timely attention. Identifying common malfunctions and understanding the necessary repairs can help keep the vehicle in peak working condition. Regular maintenance is key to preventing larger issues from developing and reducing unexpected downtime.

Engine problems are a frequent issue, often related to fuel delivery, air intake, or lubrication systems. Overheating, starting issues, or unusual noises can indicate underlying engine malfunctions. It is essential to regularly check the cooling system and oil levels to avoid costly repairs. In some cases, replacing filters or cleaning injectors can resolve minor issues before they escalate.

Transmission difficulties may arise as a result of wear and tear on moving parts. Slipping gears, difficulty shifting, or strange vibrations can be signs that the transmission system needs attention. Regular inspection of fluid levels and replacing worn-out components like clutch plates or seals can prevent major transmission failures.

Hydraulic system failures are another common issue. Loss of power, slow movement of attachments, or fluid leaks can point to problems with hoses, pumps, or valves. Ensuring that the hydraulic fluid is clean and at the correct level, along with replacing worn seals, will help maintain smooth operation.