Maintaining and repairing a spray device requires a clear understanding of its internal components. A well-organized reference guide helps users easily identify each part and its function. Whether you’re looking to fix minor issues or conduct routine maintenance, having a detailed breakdown is essential for efficient operation.

Knowing the layout of your sprayer can prevent unnecessary delays and mistakes during repairs. With the right information, it becomes easier to troubleshoot problems, order replacement parts, and ensure your equipment is running smoothly. Familiarity with the structure of the machine enhances its lifespan and performance, making it an investment in your tool’s longevity.

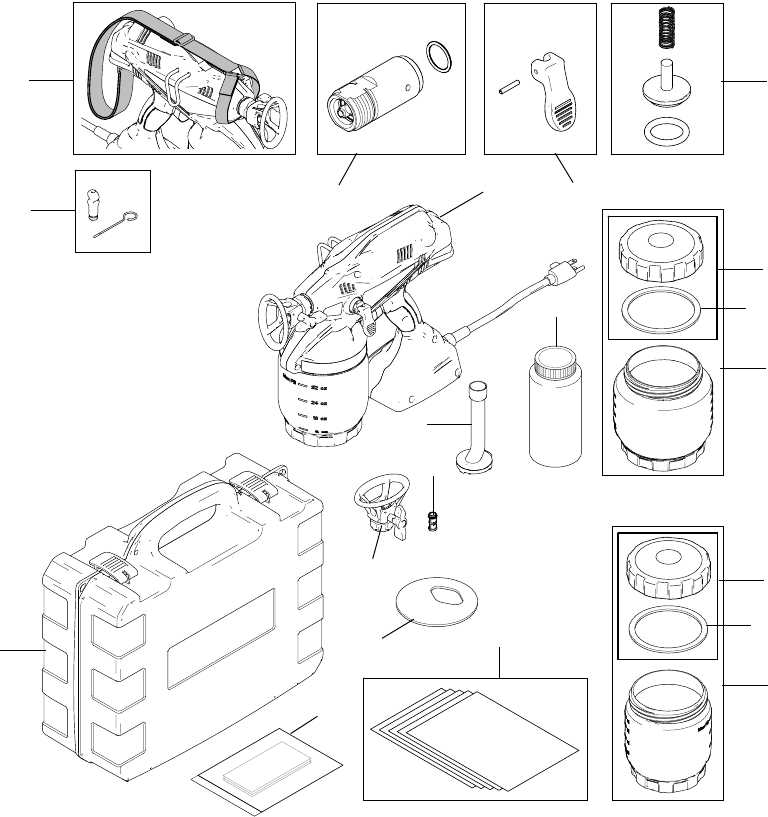

In this guide, we explore the key elements of the equipment, breaking down the key components you will need to recognize and manage. Understanding how each piece fits into the overall system will give you the confidence to handle any maintenance task effectively.

Understanding Graco 390 Parts Layout

Having a comprehensive overview of the internal structure of your sprayer is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring that the system operates efficiently, and understanding their placement and function can save time and effort when addressing issues. A well-organized layout allows for easy identification of potential problems and provides clarity during repairs.

When familiarizing yourself with the configuration, it is important to focus on how each section interacts with the others. By recognizing the key elements and their placement within the unit, you can quickly identify areas that may require attention. This knowledge will assist in making precise adjustments and replacements, ultimately extending the longevity and reliability of the equipment.

How to Identify Graco 390 Components

Recognizing the various components of your sprayer is essential for efficient repairs and maintenance. Each element within the system serves a specific purpose, and understanding their distinct characteristics allows you to pinpoint issues with ease. Familiarity with the layout and functions of these components enables smoother troubleshooting and ensures that no part is overlooked during servicing.

To identify the right components, start by consulting a detailed visual reference that labels each section of the equipment. Pay close attention to the shape, size, and material of each piece, as these factors can help you distinguish between similar components. Once you become familiar with the appearance and function of individual parts, you’ll be able to efficiently locate and address any issues that may arise.

Maintaining Your Graco 390 Sprayer Parts

Proper upkeep of your sprayer’s internal components is essential for ensuring its longevity and consistent performance. Regular maintenance not only helps prevent breakdowns but also maximizes the efficiency of the entire system. By following a structured maintenance routine, you can avoid costly repairs and extend the lifespan of your equipment.

To maintain the system effectively, start with routine cleaning to remove any build-up that might impair functionality. Regularly inspect each piece for wear and tear, as early detection can prevent more significant issues. Replacing worn-out elements promptly and lubricating moving parts can keep the machine in optimal condition, ensuring smooth operation for years to come.