Every water circulation system consists of several integral components working together to ensure smooth operation. Familiarity with each element allows for more efficient maintenance and troubleshooting. Whether you are performing routine checks or dealing with a malfunction, understanding how these elements function in unison is key.

Efficient maintenance requires a basic understanding of each unit’s role and how they interact with one another. Identifying specific components within your setup can save time and reduce unnecessary costs when repairs are needed.

As you learn more about the various units that make up the entire assembly, it becomes easier to diagnose problems, perform upgrades, and extend the lifespan of your equipment. Being able to recognize the location and function of each element can make a significant difference in system performance.

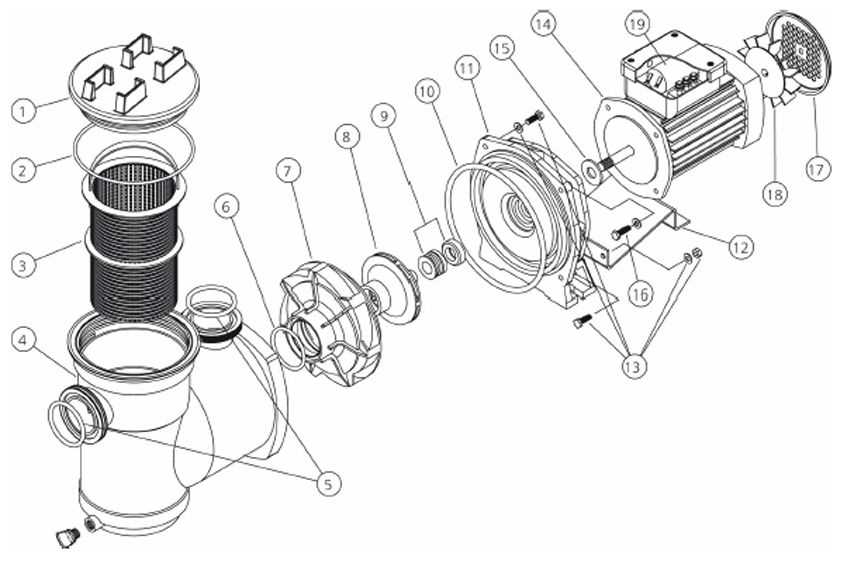

Key Components of a Pool Pump

The efficiency of a water circulation system depends heavily on the main units that enable smooth flow and filtration. Each element is crucial in maintaining proper function, from initiating water movement to ensuring optimal filtration and cleaning. Understanding the roles of these essential components helps ensure a well-functioning setup.

Motor is the heart of the system, driving the mechanical force needed for water flow. It provides the necessary power to keep the flow consistent and strong. Without it, the system would not operate effectively.

Impeller is responsible for moving the water through the system. Positioned within the motor, it converts the rotational energy from the motor into the kinetic energy needed to push the water through the filters and back into the system.

Strainer plays a critical role in preventing debris from entering and damaging the machinery. By catching leaves and other contaminants, it ensures that the flow remains uninterrupted and prevents clogging in other components.

Volute is the casing around the impeller that directs the flow of water. It helps to evenly distribute the pressure as water moves through the system, maintaining a balanced and efficient circulation process.

Understanding the function of each unit within the system provides clarity on how they work together to ensure optimal operation and longevity. Keeping these components in good condition is vital for maintaining peak performance.

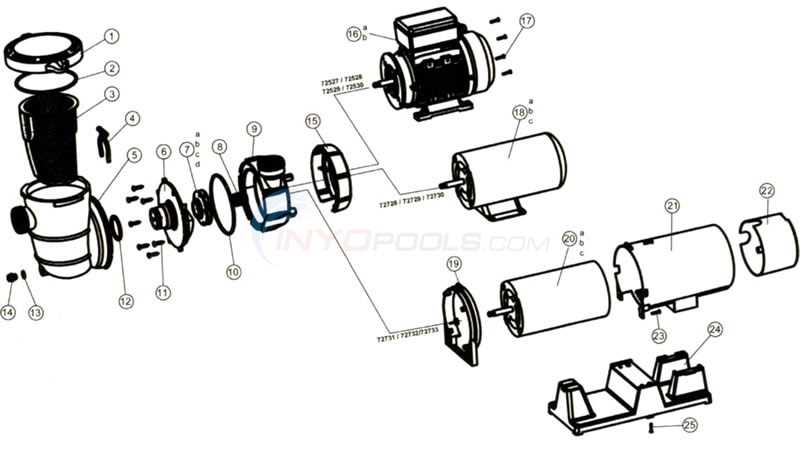

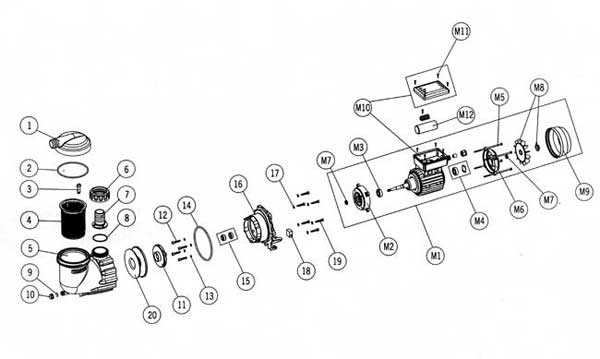

How to Read a Pool Pump Diagram

Understanding the layout and structure of a system is essential when it comes to troubleshooting or performing maintenance. A well-detailed schematic provides a clear representation of the components and their relationships. By recognizing each unit and its function, you can more easily identify issues and find solutions.

When examining a visual guide for your system, there are a few key points to keep in mind:

- Symbols and labels: Each component is represented by a unique symbol. Make sure to familiarize yourself with these, as they are standardized across most systems.

- Connections: Follow the lines and arrows that indicate how the units are connected. These lines represent water flow, power supply, or signal pathways between components.

- Orientation: Pay attention to the orientation of the schematic. Some diagrams are drawn to show the flow in a specific direction or from a certain perspective.

Additionally, components may be grouped by function or location, making it easier to understand how different elements contribute to the overall process. In some cases, color coding is used to represent different types of systems or operations, such as electrical versus mechanical parts.

With practice, interpreting a schematic becomes more intuitive, allowing for quicker diagnosis and smoother repairs. Understanding these details will help ensure the longevity and performance of your system.

Maintaining Pool Pump Parts Effectively

Proper maintenance of the components in a water circulation system is essential for ensuring long-lasting performance and preventing costly repairs. Regular upkeep can extend the lifespan of the system and enhance its efficiency. Focusing on a few key practices helps keep all units running smoothly and efficiently.

Regular Cleaning and Inspection

Cleaning the components periodically is one of the most important maintenance tasks. Accumulated debris, dirt, and mineral buildup can negatively impact the system’s performance. Regularly inspect the strainer and filter for any blockages and clear them to maintain optimal flow. This will prevent unnecessary strain on the motor and impeller.

Lubrication and Tightening Connections

By staying on top of these simple tasks, you can prevent major issues and improve the overall efficiency of your system. Regular maintenance not only saves money but also ensures reliable operation throughout the year.