Maintaining and repairing outdoor machinery requires a thorough understanding of its components and how they function together. Whether you are a professional landscaper or a DIY enthusiast, knowing how to troubleshoot and fix common issues can extend the lifespan of your tools and ensure optimal performance.

In this guide, we will walk you through the essential elements of your equipment, highlighting their functions and providing insights into reading technical diagrams. By breaking down each piece, we aim to make maintenance and repairs easier and more accessible for users of all experience levels.

Effective maintenance begins with understanding how each part contributes to the overall operation of your machine. With clear instructions and step-by-step visuals, you’ll gain the confidence to tackle any repair on your own. Save time and money by becoming familiar with the critical components that keep your garden equipment running smoothly.

Tiller Overview

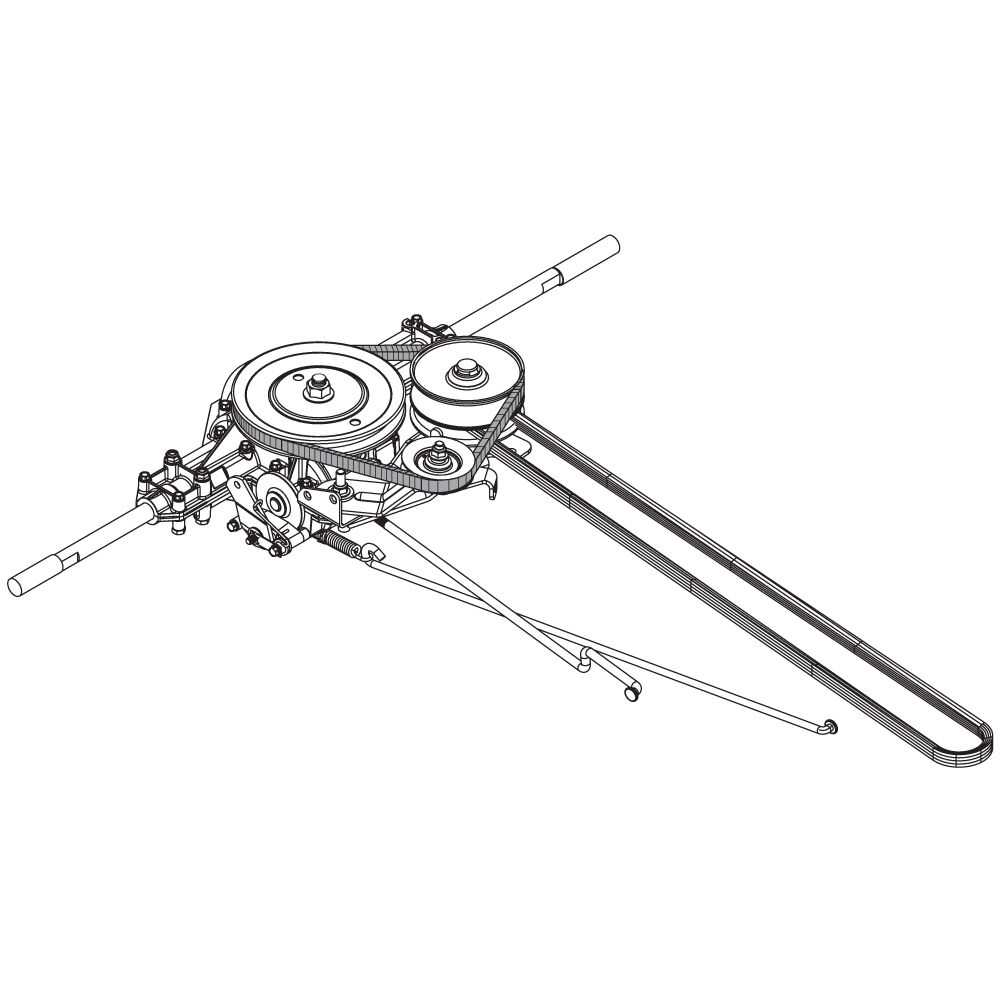

Garden machines designed for soil cultivation come in various models, each with unique features tailored to specific tasks. These tools are essential for preparing and maintaining garden beds, allowing for efficient tilling of the earth and promoting healthy plant growth. Understanding the general structure and functionality of these machines is key to ensuring they perform optimally throughout their lifespan.

Typically, such equipment consists of a robust frame, an engine, and rotating blades that break up the soil. The power source drives the components, making the machine capable of handling various types of terrain and soil conditions. Regular use of these tools can make a significant difference in achieving a well-maintained garden or lawn.

Familiarizing yourself with the key elements of your machine allows for easier maintenance and troubleshooting. This understanding is essential for diagnosing issues, ensuring proper care, and avoiding costly repairs. With the right knowledge, you can extend the lifespan of your tool and make your gardening tasks more efficient.

Understanding Tiller Components and Their Functions

Garden cultivation machines consist of several interconnected components, each playing a vital role in ensuring the equipment works efficiently. Each element of the tool is designed to perform specific tasks, and understanding these functions can help you troubleshoot issues and perform proper maintenance.

The engine serves as the primary power source, driving the various mechanisms that allow the tool to cut, break, and move through soil. The rotating blades are responsible for digging into the earth, turning the soil to improve aeration and nutrient distribution. Other components, such as the wheels and handlebar, provide control, maneuverability, and ease of operation.

By knowing the function of each part, you can better identify when something is malfunctioning. Understanding how the components interact with each other also ensures more effective use, allowing you to maintain your machine for longer periods and achieve optimal results in your gardening tasks.

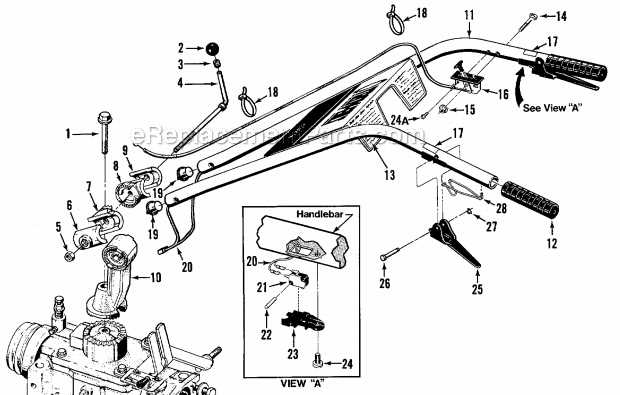

How to Read the Technical Illustration

Reading a technical illustration for your garden machinery is essential for identifying the various components and understanding how they fit together. These diagrams provide clear visuals that highlight each part, showing how they interact to ensure the proper functioning of the tool. By carefully examining the diagram, you can gain a deeper understanding of your equipment’s structure, making maintenance and repairs easier.

Identifying Key Components

The first step in interpreting the technical illustration is identifying the key components. Each part is labeled with a unique number or code, making it easier to find specific items in the parts catalog. The labels may also include additional information, such as part sizes or material details, which are crucial when replacing or repairing individual components.

- Frame and chassis: The foundation of the tool that supports other parts.

- Engine: The power unit responsible for driving the system.

- Rotating blades: The components that break and turn the soil.

- Wheels and handlebars: For maneuverability and control during operation.

Following the Connections

Once the parts are identified, the next step is to examine how they are connected. The diagram will typically show lines or arrows that indicate how each component interacts with others. These connections are important for understanding how power is transferred through the system, and where problems are likely to arise.

- Look for lines that represent power transmission from the engine to the rotating blades.

- Check for connections between the wheels and the chassis for proper alignment and movement.

Step-by-Step Guide for Maintenance

Proper upkeep of your garden machinery is essential for keeping it running smoothly and extending its lifespan. Regular maintenance prevents wear and tear, reduces the risk of breakdowns, and ensures optimal performance. This guide will walk you through the necessary steps to maintain your equipment and keep it in top condition throughout the season.

Preparing for Maintenance

Before beginning any maintenance work, ensure that the machine is powered off and cooled down. Gather the required tools, such as wrenches, screwdrivers, and cleaning supplies, to make the process more efficient. Always refer to the owner’s manual for specific instructions regarding your model.

- Disconnect the power source, if applicable.

- Wear protective gloves to avoid injury from sharp components.

- Clear the work area of debris or obstacles.

Regular Maintenance Tasks

Performing routine maintenance tasks will help keep your equipment running efficiently. The following tasks should be done regularly:

- Clean the exterior: Use a brush or cloth to remove dirt and debris from the machine’s surface.

- Inspect the blades: Check for damage or wear. Sharpen or replace them if necessary to maintain effective soil cultivation.

- Check the engine: Regularly inspect the engine for oil levels, fuel condition, and air filter cleanliness. Replace or refill as needed.

- Lubricate moving parts: Apply lubrication to gears, wheels, and other moving components to prevent friction and wear.

By following these simple steps, you’ll ensure that your equipment stays in good working condition, ready to tackle any gardening task.

Common Repair Issues and Solutions

Over time, even the most reliable garden machines can experience issues that require repair. Understanding the common problems and knowing how to address them can save you time and money. This section will highlight frequent malfunctions and provide practical solutions to get your equipment back in working order.

Engine Not Starting

If the engine fails to start, it’s often due to fuel or ignition system issues. Here are some possible causes and solutions:

- Empty Fuel Tank: Ensure that the tank is filled with fresh fuel, as old fuel can clog the system.

- Clogged Spark Plug: Inspect the spark plug for dirt or wear and replace it if necessary.

- Battery Issues: Check the battery (if applicable) and replace it if it is dead or corroded.

Machine Not Moving Properly

If your equipment is not moving as it should, there may be an issue with the transmission or wheels. Try these troubleshooting steps:

- Loose or Broken Belts: Inspect the belts that drive the wheels for signs of wear or damage. Replace any broken belts.

- Improper Wheel Alignment: Ensure that the wheels are properly aligned and that no debris is obstructing movement.

- Transmission Fluid: Check the fluid levels and condition. Low or contaminated fluid can affect performance.

By identifying the problem early and following these steps, you can resolve many common issues and keep your equipment functioning smoothly.