Proper knowledge of your tool’s internal structure is essential for effective maintenance and smooth operation. When you have a clear understanding of each element and its function, troubleshooting and repairs become easier tasks to tackle. Having access to an organized visual representation of all the key components allows you to identify and manage them with confidence.

Effective maintenance requires more than just knowing how to use your tool; it involves familiarizing yourself with the parts that keep it running efficiently. Whether it’s for routine servicing or troubleshooting, recognizing each part’s location and purpose will save time and ensure safety.

In this guide, we’ll explore how to make the most of a visual reference to enhance your tool care practices. By breaking down the assembly into its key elements, you’ll be prepared to handle any situation that arises during usage or maintenance.

Understanding Key Components of Your Tool

Every mechanical tool consists of a variety of elements, each with a specific role to ensure its proper functionality. Understanding the interaction between these elements is crucial for smooth operation and longevity. A comprehensive knowledge of the internal structure will make maintenance and troubleshooting more straightforward.

In this section, we focus on the most important components, from the motor to the cutting mechanism. Each part contributes to the overall performance, so recognizing their functions and relationships allows you to address issues quickly and perform regular maintenance effectively.

By learning how each component fits into the system, you can extend the lifespan of the tool and keep it in optimal working condition. A well-maintained tool performs better, operates more safely, and requires fewer repairs over time.

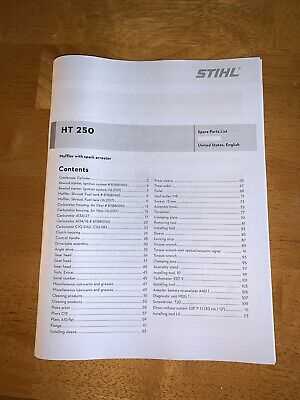

How to Identify Components in the Visual Guide

Recognizing each individual element within a tool assembly is essential for effective maintenance. A visual representation helps to clearly outline each component, making it easier to spot any potential issues or wear. Knowing how to read and interpret this guide allows for quick identification of which part needs attention.

Step-by-Step Identification Process

Begin by examining the visual guide thoroughly. Each section will be labeled or numbered, corresponding to a specific element of the mechanism. Look for highlighted or marked areas that show the essential components and their positions within the system. This layout makes it simpler to match the visual with the actual tool and spot any discrepancies.

Utilizing Labels and Descriptions

Most guides include brief descriptions alongside the images, which can provide valuable insights into the function and role of each element. Pay close attention to these labels, as they can help you distinguish between similar-looking parts and better understand how they interact with each other. In this way, you can make informed decisions during repairs or replacements.

Essential Maintenance Tips for Your Tool

Regular maintenance is crucial to ensure the longevity and optimal performance of any mechanical device. Keeping your tool in good condition not only prevents breakdowns but also enhances its efficiency. A few simple tasks, performed routinely, can extend the lifespan and prevent costly repairs.

Cleaning and Lubrication

One of the most important aspects of maintenance is keeping the tool clean. Dirt and debris can accumulate in various components, affecting their functionality. Regularly clean the moving parts and ensure that lubrication is applied where necessary. This helps reduce friction and wear, keeping the device operating smoothly.

Checking and Replacing Worn Components

Over time, certain elements of your tool may wear out or become damaged. Regularly inspect the key components to identify any signs of wear. Replacing worn-out elements early will prevent them from causing more significant issues and ensure the tool remains in top working order. Always consult the user guide for proper replacement parts and installation procedures.