When dealing with any firearm, it is crucial to understand how its components work together. This knowledge helps in proper maintenance, troubleshooting, and upgrading. A well-structured breakdown of the key elements involved can make repairs and modifications much easier.

Familiarizing yourself with the components is the first step towards mastering the assembly. Each part plays a significant role in the overall function, and knowing their exact positions and interactions ensures optimal performance and safety.

In this guide, we will explore the layout and structure of these critical components. By the end, you’ll be able to identify each piece and understand its purpose in the larger system, making your firearm handling much more effective and efficient.

Understanding the Rossi 92 Components

Each firearm is a collection of interconnected elements that function together to provide performance and safety. Understanding how these components interact is essential for both maintenance and troubleshooting. In this section, we will explore the key elements involved in the system, highlighting their roles and importance.

Key Elements of the System

The core of any firearm consists of several critical elements, each designed for a specific function. These include the trigger mechanism, the firing system, and the loading and feeding mechanisms. Together, they ensure smooth operation and safety during use. Knowing the function of each part allows for better handling and care, ensuring that everything works as intended.

Interrelation of Components

The effectiveness of the system relies on how well each piece interacts with the others. For example, the safety mechanism works in tandem with the firing system to prevent accidental discharge. Understanding these relationships is vital for identifying and resolving any potential issues that may arise during use.

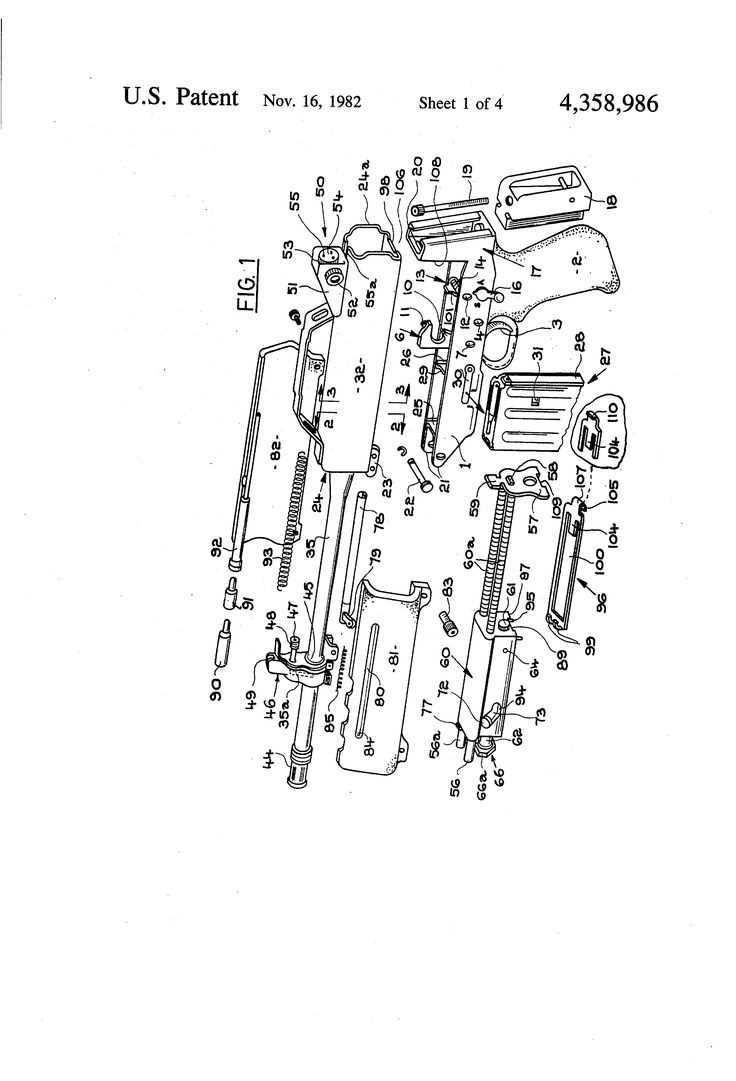

How to Read the Parts Diagram

Interpreting an assembly chart is a vital skill for anyone involved in firearm maintenance or repair. These charts provide a visual representation of how individual components are positioned and connected. Knowing how to read this information can simplify troubleshooting and enhance understanding of the system’s operation.

Understanding the Visual Layout

Most charts will use a layout that groups similar components together, allowing you to quickly identify related parts. The key is to follow the flow and see how each element fits into the larger picture. Here’s how to approach reading a typical assembly chart:

- Focus on the numbered items: Each component is typically assigned a number or code that corresponds to a part description or list.

- Look for connections: Arrows or lines often indicate how different parts connect to each other, providing insight into their relationships.

- Use a legend: Most charts will include a legend or key to help you understand what each symbol or number represents.

Interpreting the Descriptions

After identifying the components visually, refer to the corresponding list of descriptions. This will provide detailed information, such as part names, functions, and materials. By matching the visual layout with the descriptions, you can easily gain a comprehensive understanding of the firearm’s assembly.

Common Issues with Rossi 92 Parts

Like any mechanical system, firearms can experience wear and tear over time. Knowing the common issues that arise with the components can help you identify problems early and take corrective actions. Regular maintenance and a keen understanding of the potential faults will ensure smooth operation and extend the lifespan of the system.

Firing Mechanism Failures

The firing system is one of the most crucial parts of the setup. Common issues in this area include misfires or failure to discharge. This can often be caused by dirt buildup, worn-out springs, or improper alignment. Ensuring that the trigger mechanism is properly lubricated and aligned can reduce the likelihood of these problems.

Feeding and Ejection Malfunctions

Another frequent issue involves the feeding and ejection mechanisms. Problems such as failure to load rounds or improper ejection can cause significant operational disruption. These malfunctions are often due to a misalignment of the magazine, worn parts, or obstructions. Regularly inspecting and cleaning these components can help prevent jams and ensure smooth cycling of ammunition.