Farming tools are essential for cultivating the soil and preparing it for planting. Each piece of machinery has specific components that contribute to its overall function. Understanding how these individual elements work together can greatly improve the efficiency of farming operations.

Mechanical tools used for soil preparation rely on various mechanisms to break up the earth. The various parts are designed to work in harmony, ensuring that the soil is properly tilled and aerated for optimal plant growth.

By familiarizing yourself with the components of this equipment, you can gain a better understanding of how to maintain, repair, and use it effectively. This knowledge is crucial for both novice and experienced farmers aiming to maximize their productivity.

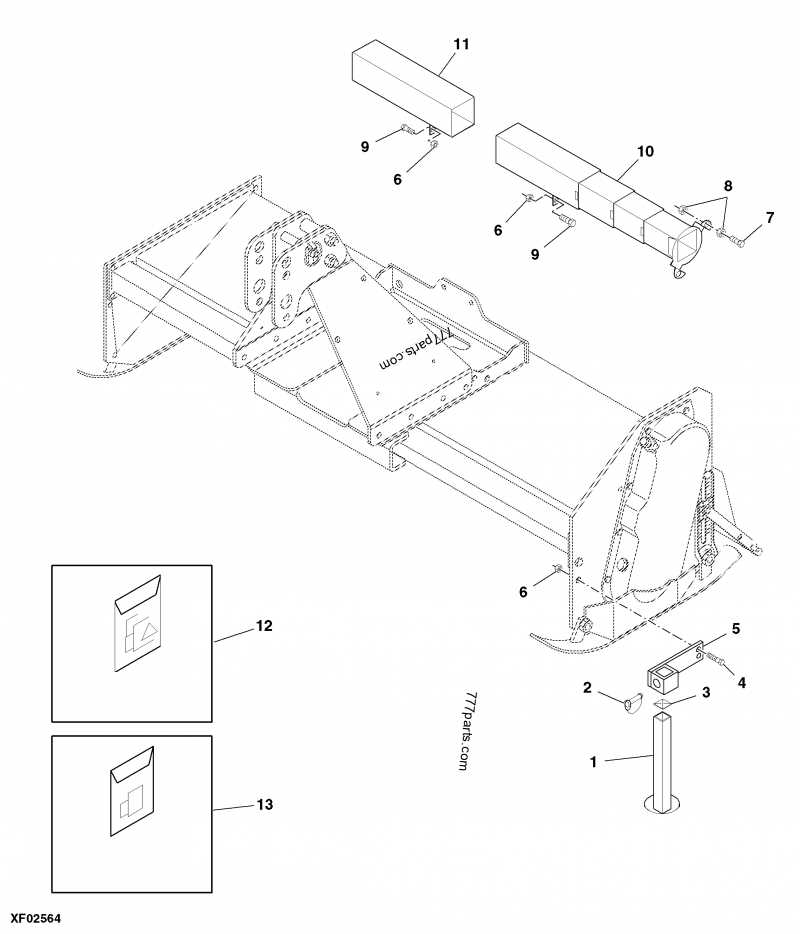

Understanding Rotary Tiller Components

Soil cultivation equipment is made up of multiple elements that work together to ensure efficient operation. Each component serves a specific function, contributing to the overall performance and durability of the machine. Knowing how these mechanisms interact is key to understanding how the entire system operates smoothly.

The main structure of the machine is designed to support and house various tools that perform different tasks, such as breaking the soil, mixing organic matter, and preparing the ground for planting. These tools must be robust and durable to withstand the harsh conditions they encounter during use.

Recognizing the role of each element within the system allows for better maintenance practices and troubleshooting when problems arise. Proper knowledge of the machinery’s inner workings ensures that users can keep the equipment in top condition and make the most of its capabilities.

Key Parts of a Rotary Tiller Explained

Every soil preparation machine consists of several key elements that contribute to its efficiency and functionality. These components are designed to perform specific tasks, ensuring that the soil is properly worked for planting. Understanding the role of each mechanism helps in optimizing performance and ensuring the equipment lasts longer.

The main tool used for soil breaking is typically made up of rotating blades or blades attached to a shaft. These blades are designed to dig into the earth, allowing the machine to break up compacted soil and mix in organic material. Other essential components include the frame, which supports all other mechanisms, and the drive system that powers the machine’s rotation.

Additionally, the wheels or traction system provide mobility, allowing the machine to move across fields. Without a reliable set of wheels or tracks, the equipment would not be able to cover large areas efficiently. Each component, from the blades to the wheels, plays a vital role in ensuring the machine functions as intended.

How Each Tiller Part Functions

Each element of soil preparation equipment plays a distinct role in ensuring the machinery performs its tasks effectively. From breaking up compacted earth to mixing in nutrients, every component contributes to the machine’s overall functionality. Understanding the specific function of each mechanism helps optimize usage and maintenance.

The rotating blades or discs are crucial for digging into the soil, cutting through tough ground, and breaking it into smaller pieces. These blades rotate at high speeds, loosening the soil for planting. The frame holds everything in place, providing stability during operation, while the drive system powers the movement of the blades.

The traction system, consisting of wheels or tracks, enables the machine to move across the field. The wheels help maintain consistent speed and direction, ensuring uniform coverage of the soil. By understanding how each of these elements functions, users can ensure their equipment runs smoothly and remains efficient throughout its lifespan.