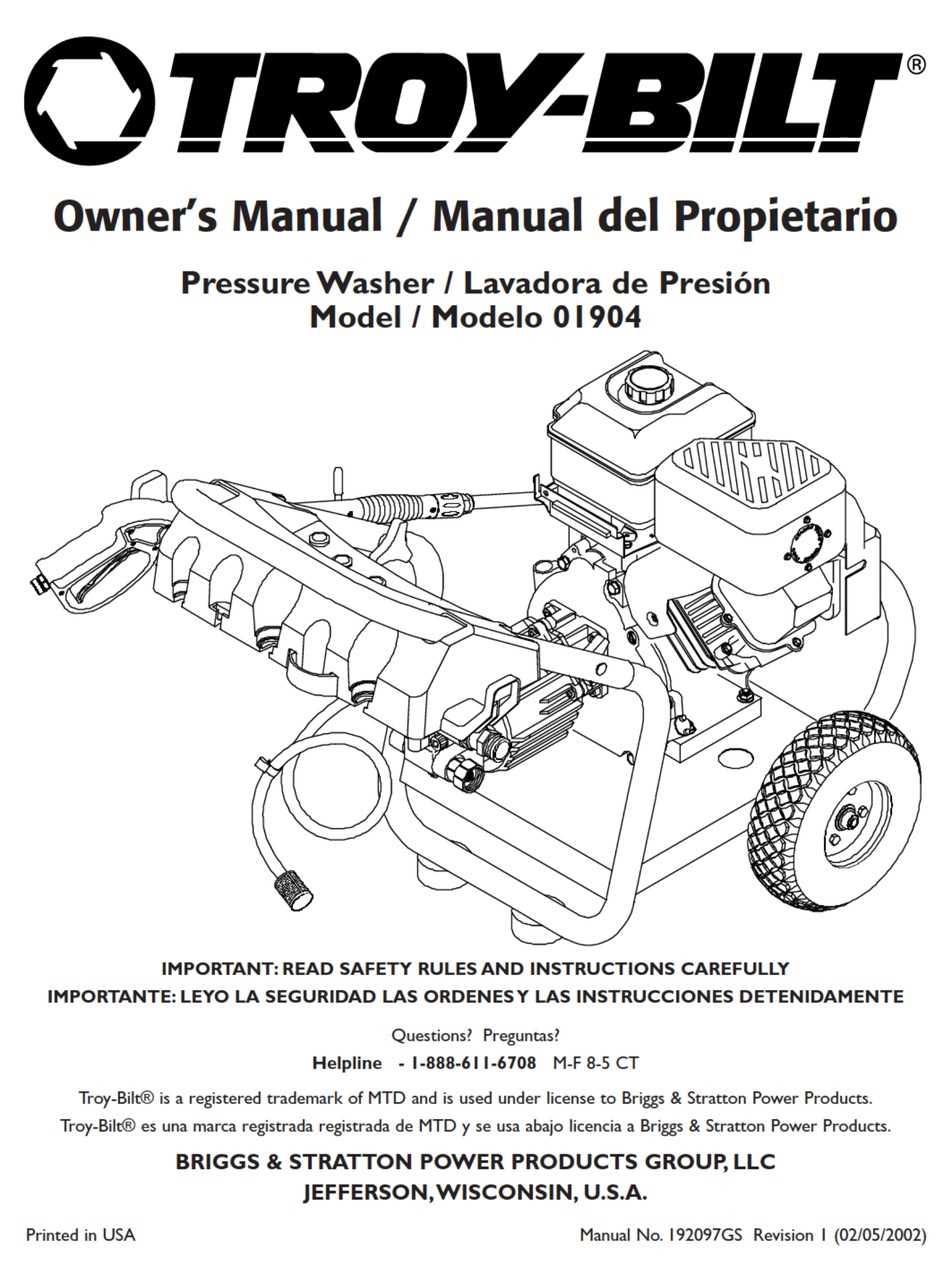

Maintaining and repairing your outdoor cleaning tool requires a solid understanding of its internal structure. Familiarizing yourself with the different elements and their functions can make troubleshooting and replacements much easier. Whether you are facing a malfunction or simply looking to upgrade certain components, having a clear overview is crucial for effective maintenance.

Knowing how each part fits into the overall system ensures you can identify the source of any issue and quickly find the correct replacement. This knowledge not only improves the lifespan of your equipment but also helps in making informed decisions during repairs. By visualizing the assembly and connections of the main components, you can approach maintenance tasks with greater confidence.

Understanding the Components of Your Cleaning Equipment

To maintain your outdoor cleaning tool effectively, it’s essential to grasp how each component contributes to the overall function of the system. Each element, from the motor to the water delivery mechanism, plays a vital role in ensuring the equipment works properly. Having a clear understanding of these individual parts allows for easier identification of issues and more efficient repairs.

Main Function of Key Elements

The core elements of your equipment are designed to work in tandem to provide optimal cleaning performance. The engine generates the power needed for operation, while the pump directs water through the system with high efficiency. Understanding how these components interact will help you spot potential problems, whether it’s a power failure or a blockage in the water flow.

Identifying Issues and Troubleshooting

With a basic knowledge of your equipment’s structure, you can easily troubleshoot any malfunction. Common issues may include poor performance, leaks, or irregular water flow. By understanding where these problems could stem from, whether it’s a damaged pump or worn seals, you can approach repairs with the right focus and speed. Keeping an eye on key parts will also help in preventing future breakdowns.

How to Identify Pressure Washer Parts

Recognizing the various components of your cleaning equipment is key to ensuring proper maintenance and troubleshooting. Each individual part has a specific role to play in the operation of the machine, and understanding their function will allow you to identify problems quickly and accurately. This knowledge is essential when you need to replace a malfunctioning element or upgrade a worn-out part.

Common Components and Their Functions

The main elements in your cleaning system are generally the motor, pump, hoses, and trigger mechanism. The motor powers the entire system, while the pump is responsible for generating the necessary pressure. Hoses direct the water flow, and the trigger mechanism controls the release of water. By identifying these key components, you can quickly locate the source of any malfunction.

How to Examine and Verify Parts

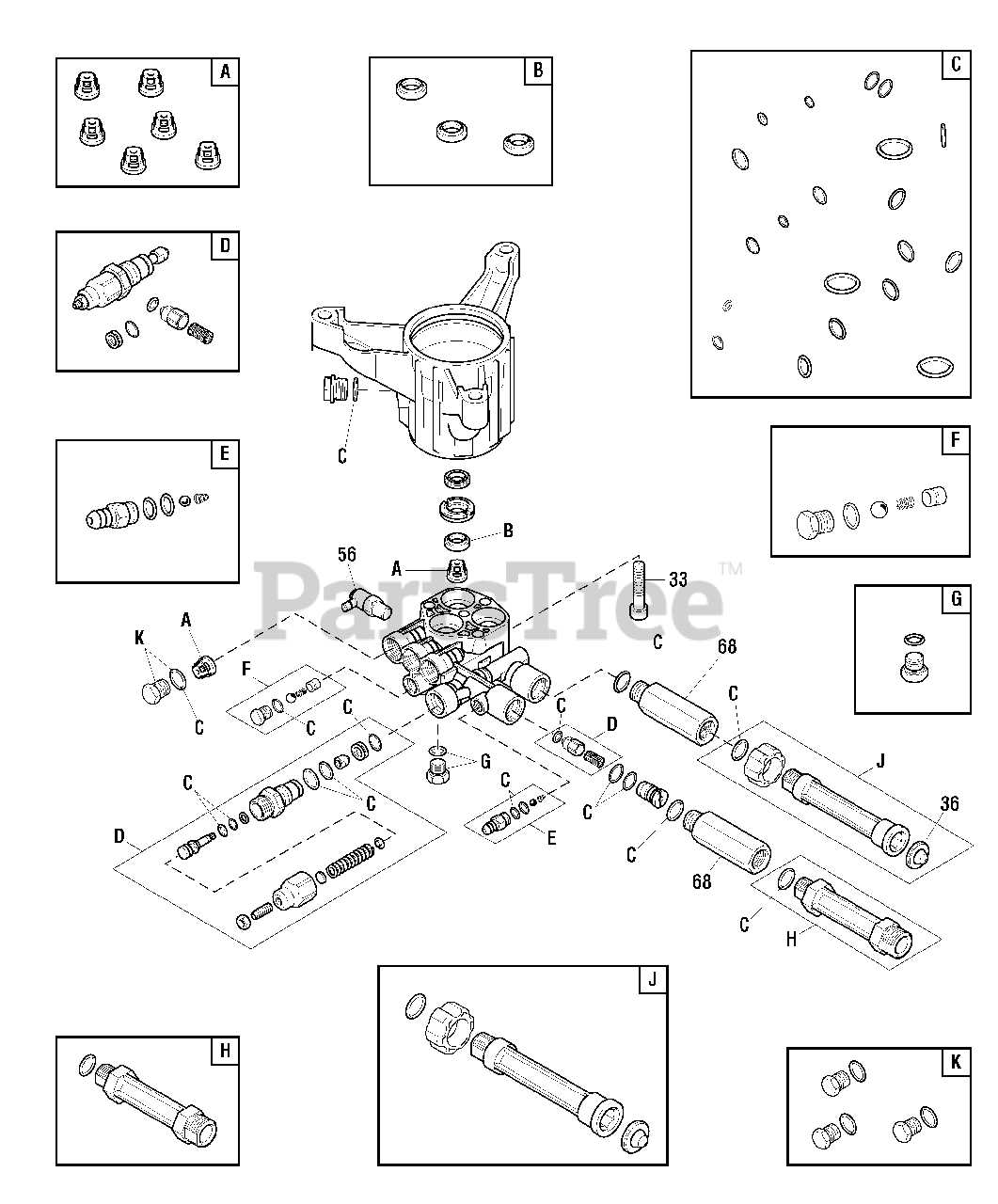

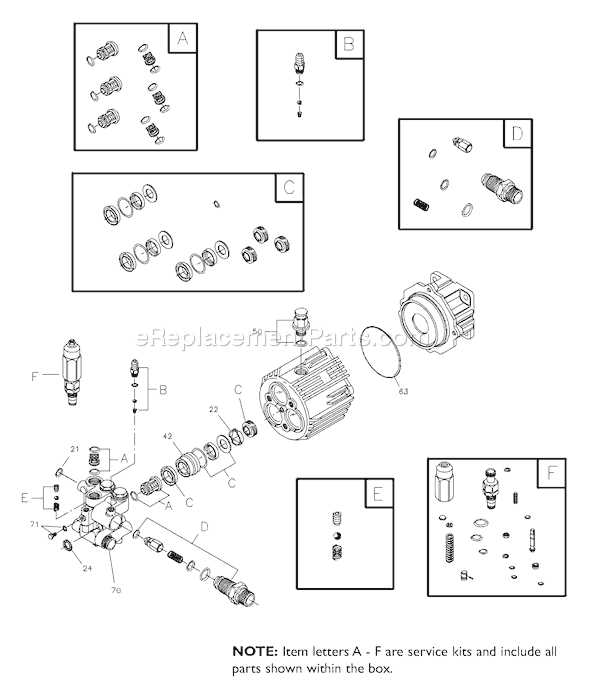

Start by inspecting each component for any signs of wear, corrosion, or damage. Pay close attention to any parts that show visible signs of leaking or wear. Hoses should be free from cracks, while the pump should operate smoothly without any unusual noise. If you’re unsure about the condition of a specific element, referring to a detailed manual or a schematic can provide valuable guidance in confirming the part’s identity and condition.

Common Issues and Replacement Parts Guide

When using outdoor cleaning equipment, it’s not uncommon to encounter various issues that can affect its performance. Understanding the most frequent problems and knowing how to address them with the correct replacements is crucial for maintaining the machine’s efficiency. Whether it’s a loss of power, leaking, or improper water flow, identifying the issue early can save time and money on repairs.

Frequent Malfunctions and Their Causes

Some of the most common issues include a malfunctioning motor, reduced water flow, or leaks in the system. A lack of power often points to a problem with the motor or its components, such as a worn-out bearing or damaged wiring. If you’re experiencing weak water pressure or inconsistent flow, the pump may need attention, often due to clogged or damaged internal parts. Leaks typically occur around hoses, seals, or connections that have worn down over time.

Choosing the Right Replacement Parts

Once the problem is identified, selecting the right replacements is essential for proper repair. For issues like a malfunctioning pump, replacing it with an OEM (Original Equipment Manufacturer) version ensures compatibility and optimal function. Similarly, damaged hoses or seals should be replaced with high-quality, durable alternatives. Regular inspection and early replacement of worn components will help extend the life of your equipment and maintain peak performance.