Snow removal equipment plays a crucial role in maintaining safe and accessible roads during the winter season. Understanding the structure and individual elements of such machinery is essential for proper maintenance and operation. By knowing each component’s function, users can ensure smoother operation and extend the equipment’s lifespan.

In this section, we will explore the essential components of a popular snow removal system. Whether you are a seasoned operator or a first-time user, recognizing each part’s role will help you manage repairs, replacements, and overall care effectively. A well-maintained system ensures reliability and efficiency, even in the harshest conditions.

Regular maintenance and timely inspections can prevent costly repairs and downtime. Proper knowledge of the equipment’s design will guide you in addressing potential issues before they arise. Let’s dive into the details of the key elements that make up this powerful snow removal tool.

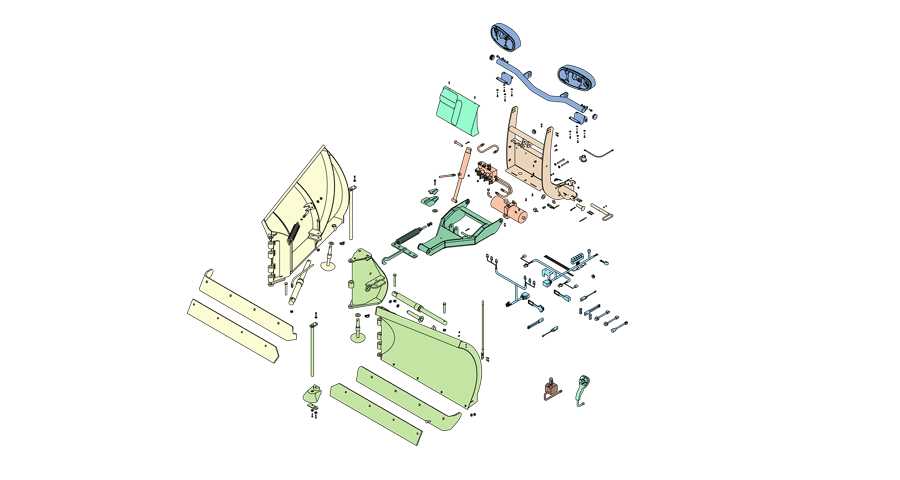

Boss RT3 V Plow Component Breakdown

When it comes to heavy-duty snow removal, understanding the design and layout of your equipment is crucial for efficient operation. Each element plays a specific role in ensuring optimal performance, making it easier to address maintenance needs and repairs. A comprehensive knowledge of each section’s function will help you keep your system running smoothly throughout the season.

Key Functional Elements

The structure of snow clearing machinery involves several core components that work together. From the frame that provides stability to the lifting system that allows for precise adjustments, every part serves a specific purpose. These elements are designed to enhance maneuverability and durability, especially in challenging weather conditions.

Maintaining Optimal Performance

Understanding how each component contributes to the overall efficiency of the system allows for better care and maintenance. Regular checks on critical elements, such as hydraulic components and control systems, will help prevent performance issues. Timely intervention with maintenance can significantly reduce repair costs and extend the machinery’s operational life.

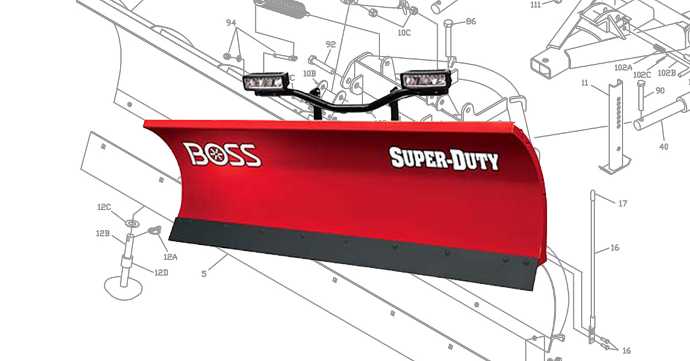

Understanding the Key Parts of Boss Plow

Every piece of snow removal equipment consists of various components that collectively ensure efficient operation. Each part plays a vital role in the overall performance, and understanding these elements is essential for anyone operating or maintaining the machinery. Recognizing the function of each section helps prevent operational issues and reduces the risk of unexpected breakdowns.

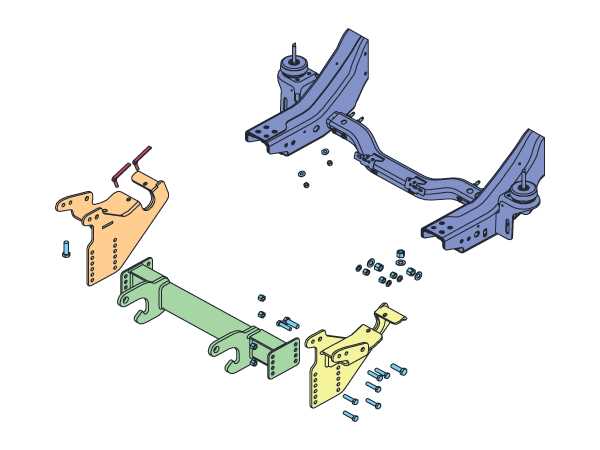

Main Structural Elements

The framework of snow removal systems is designed to provide strength and stability. From the base structure to the attachment points, these elements ensure that the machinery remains functional even under the toughest conditions. They provide the necessary support for both movement and operation, ensuring that the rest of the components function correctly.

Operational Mechanisms

Within the equipment, the operational mechanisms allow for precise movement and control. These include hydraulic systems that control lifting and angling, as well as the drive mechanisms that enable the machine to move effectively. Understanding how these systems interact ensures that users can maintain smooth and reliable functionality throughout the winter season.

How to Maintain Boss RT3 V Plow Parts

Proper maintenance is key to extending the lifespan of your snow removal equipment and ensuring it operates at peak performance. Regular care of the essential components helps avoid costly repairs and ensures reliable function during critical snow-clearing tasks. Understanding the necessary upkeep for each element ensures smooth operations throughout the season.

Hydraulic System Care

The hydraulic system plays a vital role in controlling the movement and adjustment of the equipment. Regularly checking fluid levels and inspecting for leaks will prevent performance issues. Additionally, cleaning the system and replacing worn seals ensures smooth operation, preventing malfunctions during use.

Frame and Structural Maintenance

Keeping the frame and support structures in optimal condition is essential for maintaining overall stability. Regularly inspecting for wear and tear, checking for rust, and cleaning any debris will prevent long-term damage. Addressing any issues early on can avoid more extensive repairs and keep the machinery in working order through harsh weather conditions.