When operating construction equipment, knowing the internal structure is essential for efficient functioning and troubleshooting. Each machine consists of various interconnected elements that contribute to its overall performance. Familiarity with these components ensures proper maintenance, reduces downtime, and improves productivity on the job site.

Identifying and understanding each part helps operators and technicians identify issues quickly and take necessary actions to address them. This knowledge also assists in making informed decisions when purchasing replacements or performing upgrades.

Proper maintenance practices can prolong the life of machinery, and recognizing the role of each component plays a significant role in preventing costly repairs. Whether you’re working with large-scale equipment or smaller devices, understanding the core elements is a critical step toward achieving optimal performance.

Understanding Mixer Machine Components

Each construction machine is made up of several essential elements that work together to ensure smooth operation. Familiarity with these components allows operators to make quick adjustments, maintain the equipment, and troubleshoot any issues that may arise. Recognizing the key functions of each part ensures that the machine runs efficiently, avoiding unnecessary downtime or costly repairs.

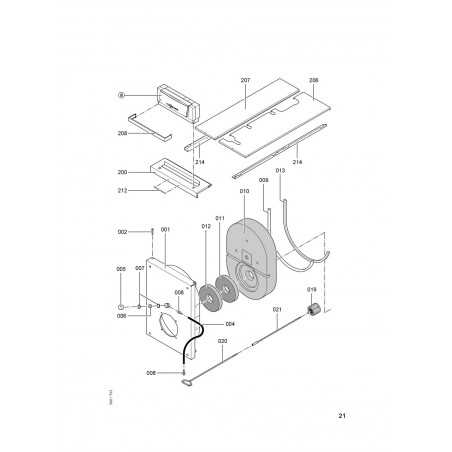

The central components of the device include the motor, gears, and moving parts that facilitate the mixing process. Proper understanding of how these elements interact with one another is crucial for effective maintenance and troubleshooting. Regular inspections help identify wear and tear on vital parts, preventing potential breakdowns.

Maintenance is made easier when the operator is well-versed in the individual roles of each part. Knowing which components require attention during specific intervals of use ensures that the machine operates at peak performance. With proper care, these machines can serve reliably for extended periods, contributing to higher efficiency on the worksite.

Key Parts in Mixer Machines

Construction equipment relies on several critical elements that ensure it performs effectively and efficiently. Understanding the key components that drive the machine’s operation is essential for operators and maintenance teams alike. These main components work in harmony to achieve the desired result and require regular inspection to maintain optimal function.

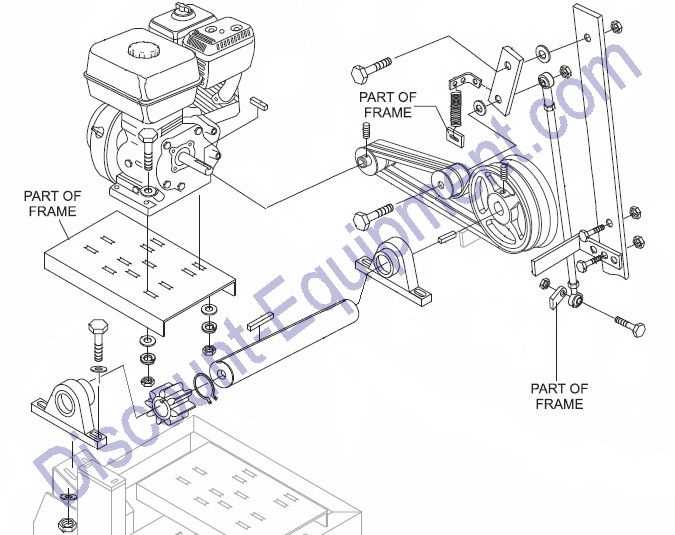

Drive Mechanism

The drive mechanism plays a central role in powering the machine. It includes the motor, gearbox, and connecting drive belts that convert energy into movement. These components need to be in top condition to prevent operational delays or failures. Regular checks and timely lubrication are essential for keeping the drive system running smoothly.

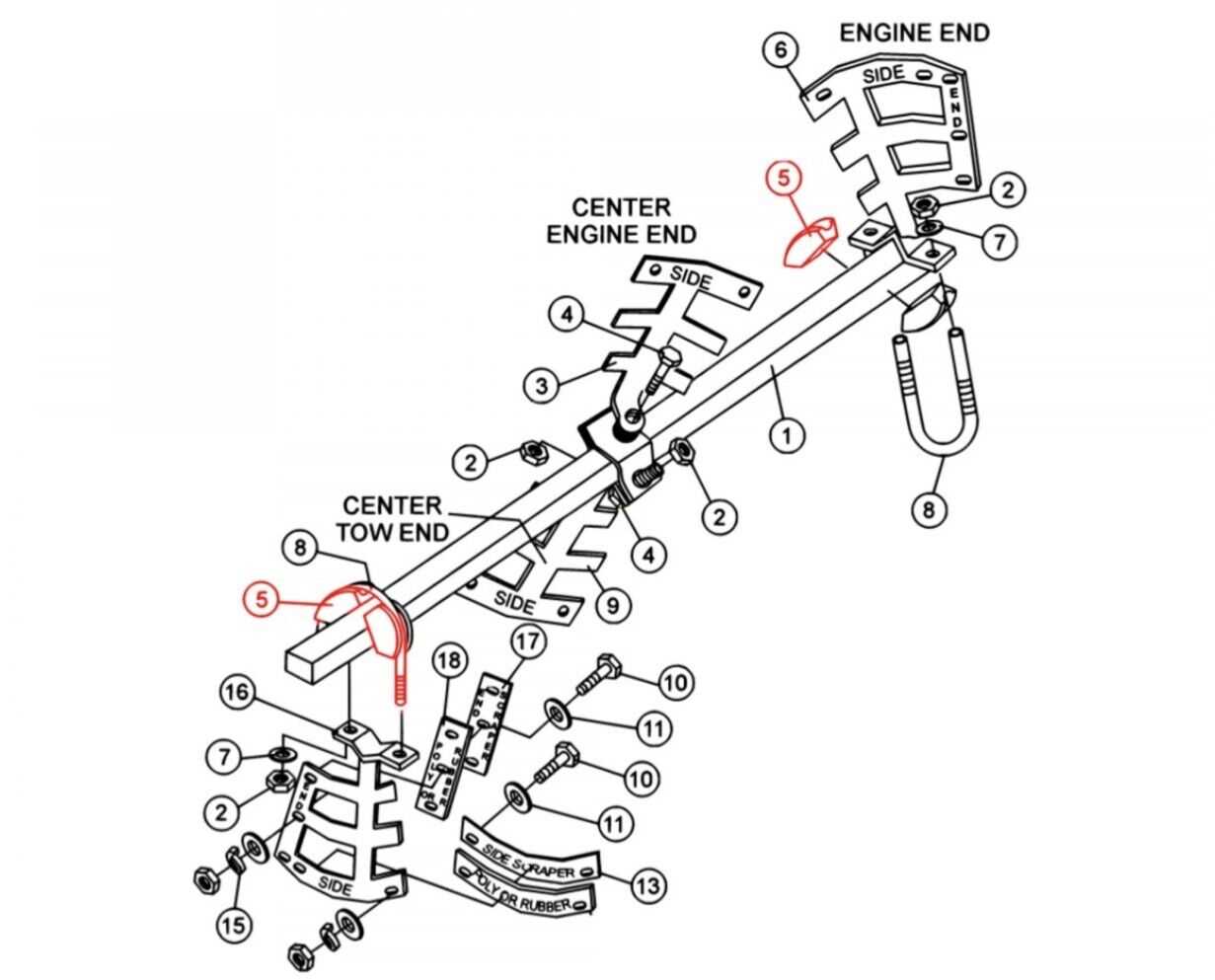

Rotating Drum and Blades

The rotating drum, along with the attached blades or paddles, is responsible for the core task of mixing materials. Proper alignment and balance of these parts are crucial to ensure even blending and prevent strain on the system. Over time, wear on the blades or drum may occur, requiring replacement or adjustment to maintain efficiency.

How to Maintain Your Mixer Machine

Maintaining construction equipment is crucial for ensuring longevity and preventing unexpected failures. Regular upkeep of all critical components helps maintain smooth operation and avoids costly repairs. By staying on top of maintenance, operators can ensure that the machine performs efficiently, providing reliable service on the job site.

Inspecting and cleaning the equipment regularly should be a top priority. Dust, dirt, and debris can accumulate over time and cause parts to wear out faster. Ensuring the exterior and interior parts are free from obstructions can prevent unnecessary strain on the motor and other moving elements.

Lubricating the moving parts is another vital step in maintaining the machine. Gears, belts, and other components benefit from periodic lubrication, which reduces friction and prevents overheating. This simple but effective maintenance task can significantly extend the life of your equipment.