Effective maintenance of industrial machinery relies heavily on understanding its internal mechanisms and structure. Having a clear visual guide to all the key components of the equipment can greatly simplify repair and service tasks. Identifying individual parts and knowing their functions is crucial for ensuring smooth operation and avoiding costly downtimes.

In this section, we’ll explore how to interpret the assembly and layout of critical elements in your machine. From small, intricate components to larger structural parts, a comprehensive overview helps in troubleshooting and performing maintenance tasks with ease. Whether you’re a technician or a user, familiarity with the equipment’s design will enhance both safety and efficiency in daily operations.

Understanding Equipment Components

Each piece of machinery is composed of various elements that work together to ensure optimal performance. Recognizing these elements and their roles is essential for anyone involved in the maintenance or operation of industrial equipment. Whether you’re troubleshooting an issue or performing routine servicing, a solid understanding of each component is necessary to ensure proper functioning and longevity of the machine.

Key Functional Elements

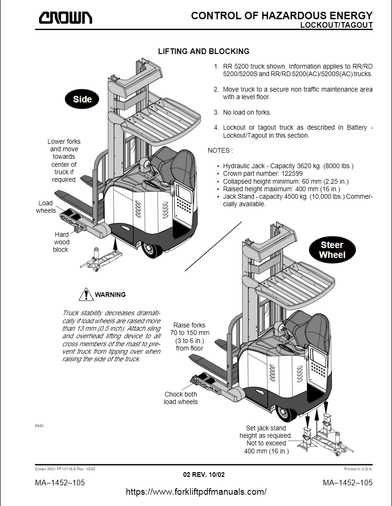

The core components of any machine are responsible for its primary operations, such as movement, lifting, and stability. These elements include mechanical, hydraulic, and electrical systems, all of which must work in harmony. Familiarity with these systems helps identify where potential issues may arise, enabling faster repairs and minimizing downtime.

Structural and Safety Features

In addition to the functional parts, machines also have structural elements that contribute to their durability and safety. Frames, support beams, and safety systems like brakes and stabilizers are critical for ensuring both the integrity of the equipment and the safety of the operator. Understanding these features allows for proper maintenance and timely detection of any wear or malfunction.

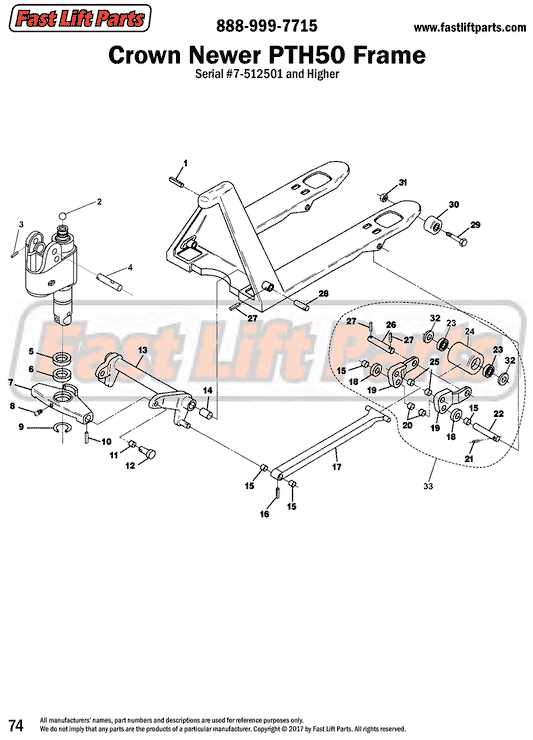

How to Read a Machine Components Illustration

Understanding how to read a visual representation of your equipment’s structure is key to effective maintenance and repair. These illustrations serve as detailed guides, breaking down the intricate elements that make up the machine. By interpreting these images properly, you can easily locate and identify parts, determine how they function, and understand their relationship within the entire system.

To effectively read these guides, it’s essential to familiarize yourself with common symbols and labels used in the visual representations. Most of these illustrations will show components in a simplified, clear manner with corresponding part numbers and descriptions. Recognizing these symbols will allow you to identify components quickly and accurately during both troubleshooting and servicing tasks.

Another important aspect is understanding the layout of the parts. Typically, these guides are organized by sections of the machine, such as the engine, hydraulics, or lifting mechanism. By following these logical groupings, you can narrow down your search and focus on the specific area you need to inspect or repair.

Essential Components for Equipment Maintenance

Regular maintenance is critical to keep machinery functioning at its best. Key components require frequent attention to prevent wear and tear that could lead to malfunctions. Identifying and understanding the most vital elements of the system helps ensure proper upkeep and minimizes the risk of unexpected breakdowns. Proper care of these elements is essential for maximizing efficiency and extending the equipment’s lifespan.

Hydraulic systems, for example, are crucial for the operation of lifting and lowering mechanisms. Ensuring that the hoses, pumps, and fluid levels are regularly checked and maintained can prevent costly repairs. Additionally, mechanical parts like bearings, motors, and brakes should be closely inspected for signs of wear, as they are essential for safe and efficient operation.

Electrical systems also play a significant role in the overall functionality of the machine. Batteries, wiring, and control panels need to be regularly tested to ensure everything is running smoothly. Keeping these systems in good condition reduces the likelihood of malfunctions that could disrupt operations or cause safety hazards.