Proper maintenance of your home appliances requires a good understanding of their inner workings. Being familiar with the individual components and how they interact can save you time and effort when repairs are needed. Recognizing the various elements that make up the machine helps in diagnosing any issues that arise.

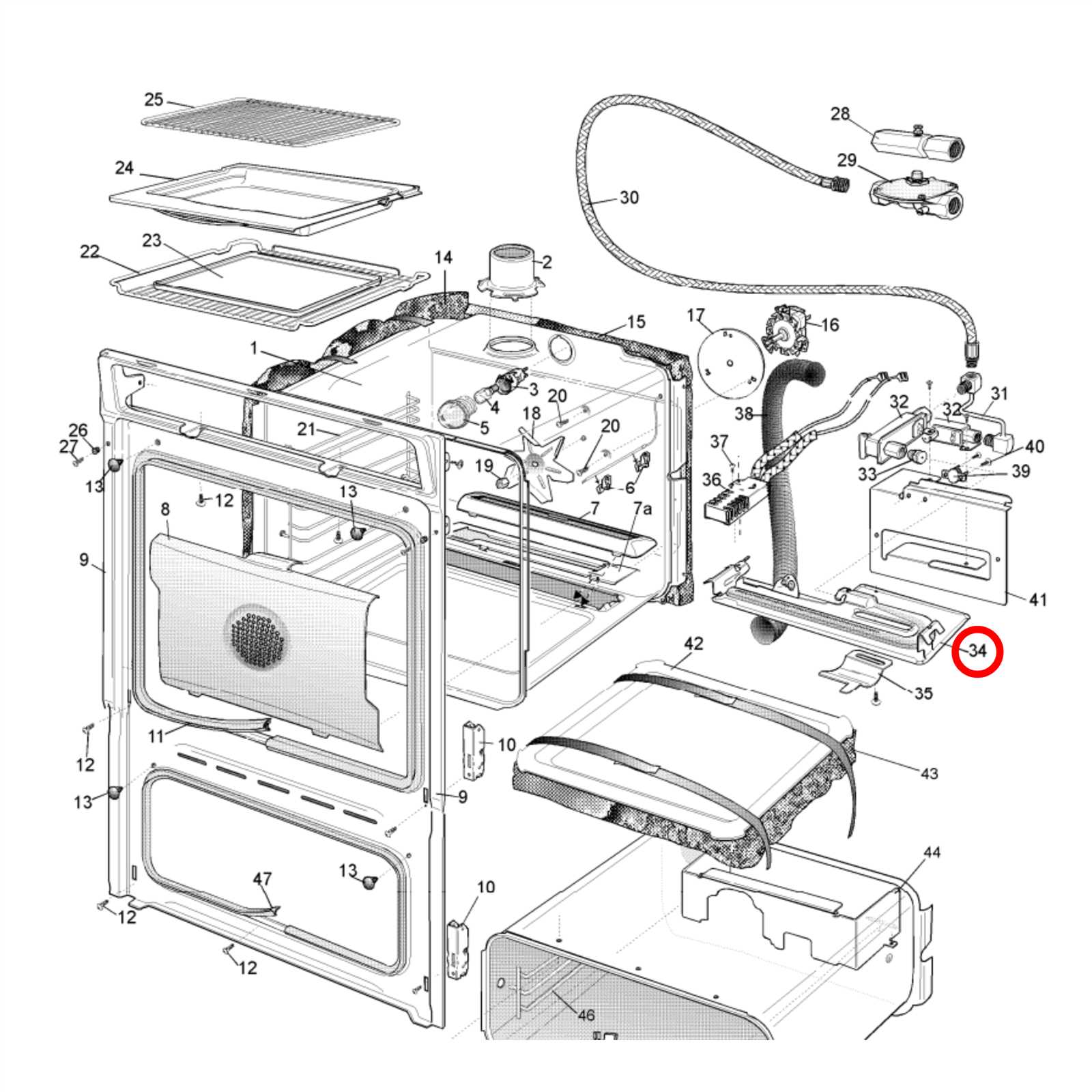

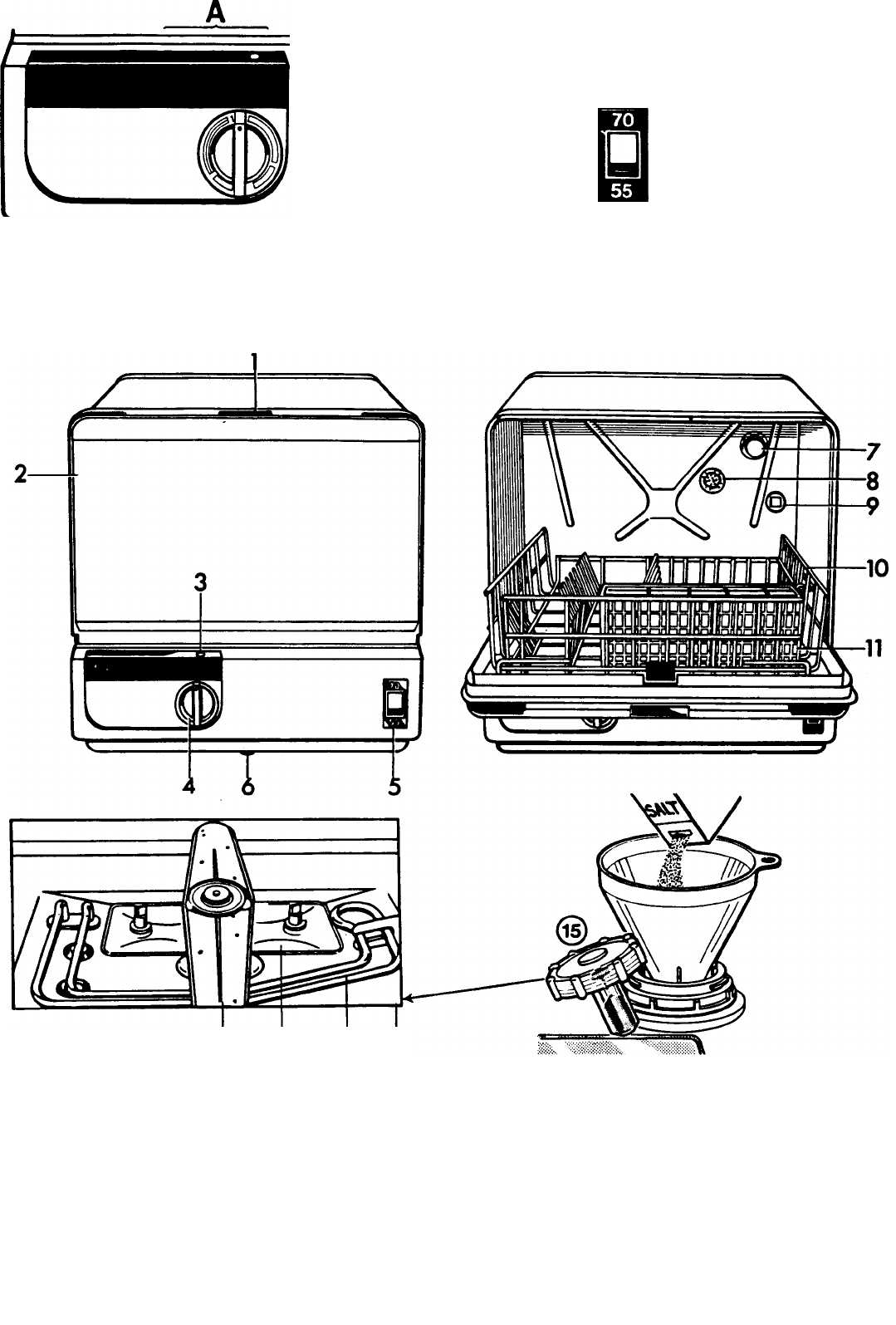

Having access to a clear visual representation of these components is essential for any repair process. Whether you’re troubleshooting an issue or performing routine maintenance, knowing what each part does and where it’s located is crucial. Understanding these visuals can greatly simplify even the most complex repairs.

By becoming acquainted with the inner structure and function of your appliance, you can confidently approach maintenance tasks. This knowledge empowers you to handle minor issues on your own and make informed decisions when professional help is needed.

Understanding Appliance Components

Every appliance is made up of various elements that work together to ensure its proper functioning. To effectively troubleshoot or maintain a machine, it’s important to know how each individual component contributes to its overall performance. Familiarizing yourself with these components helps in identifying issues quickly and efficiently.

Key components of the system include the motor, pump, control unit, and valves, all of which play vital roles in the operation of the machine. Each part has a specific function that supports the overall workflow, whether it’s directing water flow, powering movement, or regulating temperature. A clear understanding of these elements is essential when diagnosing problems or planning maintenance.

By learning how the various elements are connected, you can gain a better sense of the overall operation. Knowing where each component fits into the larger system allows for quicker identification of malfunctions, making repairs simpler and more effective. This knowledge also reduces the need for outside help in routine maintenance tasks.

Identifying Key Parts in Your Appliance

Knowing the essential components of your appliance is crucial when performing maintenance or addressing issues. By recognizing the main elements, you can more easily pinpoint problems and make necessary repairs. Understanding the function of each part helps to streamline the troubleshooting process and avoid unnecessary disassembly.

Below is a table outlining some of the key components you should be familiar with:

| Component | Function |

|---|---|

| Motor | Powers the movement of internal mechanisms and drives essential functions. |

| Pump | Moves water through the system, ensuring effective cleaning and rinsing. |

| Control Unit | Regulates all settings and operations, including cycle selection and timing. |

| Spray Arm | Distributes water evenly throughout the unit for thorough cleaning. |

| Drain Valve | Directs wastewater out of the machine at the end of each cycle. |

Having a solid understanding of these components enables you to quickly assess what might be causing any disruptions in performance. Knowing how each part functions allows for targeted repairs and prevents unnecessary disassembly.

How to Read a Maintenance Component Layout

Understanding how to interpret a layout of internal components is essential when performing repairs or maintenance. These illustrations provide a detailed view of the appliance’s structure, showing how each element fits together and functions. Learning to read these visuals allows for efficient identification of parts that need attention or replacement.

Understanding Symbols and Labels

Most visual representations use various symbols and labels to indicate the function and location of each part. These labels typically correspond to a list of components, making it easier to match the image with the actual unit. Common symbols include arrows for flow direction, numbers for part identification, and letters for components grouped together.

Following Component Connections

In addition to part identification, these layouts often show how the components are connected, whether through hoses, wires, or mechanical linkages. By understanding these connections, you can identify which parts may be affecting others and make targeted repairs. Pay attention to the positioning and orientation of each part to ensure accurate reassembly after maintenance.

Interpreting Layouts for Quick Repairs

When facing an issue with your appliance, quickly identifying the source of the problem is crucial for effective repairs. Interpreting the layout of internal components can save you time and help you avoid unnecessary disassembly. A clear understanding of these visual guides can point you directly to the malfunctioning part, allowing you to perform targeted repairs without frustration.

Steps to Read and Interpret the Layout

- Examine the overall structure: Begin by reviewing the full illustration to get a sense of the appliance’s layout.

- Identify the key components: Locate the main parts that are involved in the function you are troubleshooting.

- Look for problem indicators: Many diagrams show areas where issues commonly arise. Highlight these sections first.

- Trace connections: Understanding how parts are interconnected helps in pinpointing the cause of the issue more effectively.

Using the Layout for Efficient Troubleshooting

Once you have identified the potential areas for concern, you can take quick action by focusing on the most likely culprits. For instance, if a pump is malfunctioning, the layout will show you its connection to the motor, helping you understand the flow of power and water. This direct approach minimizes unnecessary steps and speeds up the repair process.

Common Issues with Appliance Components

When maintaining or repairing your appliance, it’s important to be aware of the common problems that can arise with individual elements. These issues can affect the overall performance, causing inefficiency or complete failure of certain functions. Understanding these frequent malfunctions can help in identifying and fixing problems quickly before they escalate.

One of the most common issues is a malfunctioning pump, which can prevent proper water circulation, leading to ineffective cleaning. Another frequent problem is with the control unit, where a faulty timer or selector can cause cycles to malfunction. Additionally, blocked or damaged valves can hinder water flow, causing the appliance to fail during use.

Being aware of these typical failures and knowing where to look in your appliance’s structure can save time during troubleshooting. Identifying the root cause of a problem early on often leads to a simpler solution, reducing repair costs and extending the appliance’s lifespan.