For efficient operation and maintenance of any complex machinery, a clear understanding of its internal structure and individual elements is crucial. Knowing how each component interacts ensures the longevity and optimal performance of the system.

In this guide, we explore the various elements of mechanical systems commonly used in aerial access vehicles. Identifying these components helps users recognize their roles and troubleshoot potential issues with ease.

Whether you’re an operator or a technician, mastering the configuration and function of each part will significantly improve your ability to maintain and repair the equipment. With detailed visuals and explanations, you’ll gain confidence in diagnosing problems and performing routine checks.

Understanding the Aerial Access System

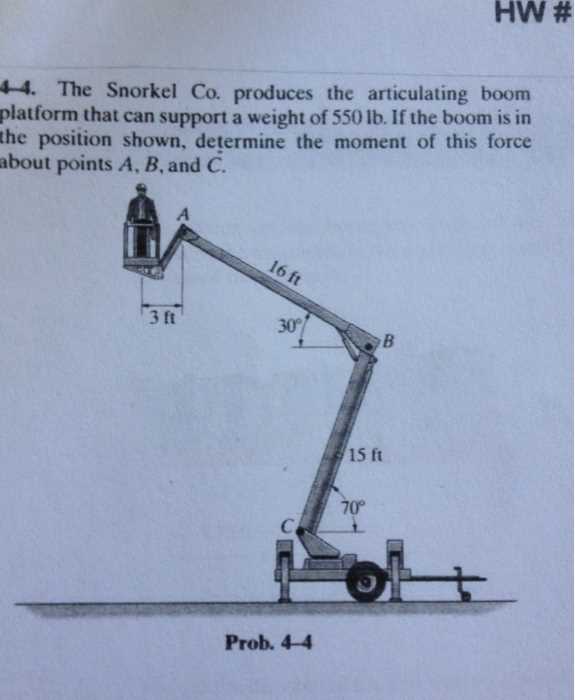

Mechanical access platforms are complex machines designed to elevate operators safely to high working areas. These machines are equipped with a variety of essential elements that work in harmony to ensure smooth and secure operation. A thorough understanding of how these systems function is key to their safe use and efficient maintenance.

The system is made up of multiple interconnected components, each serving a specific function. From the hydraulic mechanisms that control movement to the structural elements that provide stability, every part plays an important role. Understanding their configuration and interaction helps in troubleshooting and repair, reducing downtime and enhancing performance.

Proper operation and care of these machines require familiarity with the structure, including the key features responsible for raising and lowering the platform. Familiarizing yourself with these components ensures that any issues can be quickly diagnosed and addressed, keeping the system in optimal working condition.

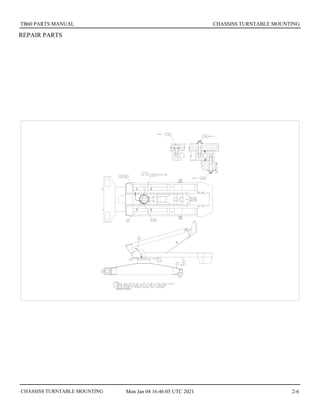

Identifying Key Components in the Diagram

To effectively maintain and operate complex machinery, it is essential to recognize the critical components that make up the system. Understanding how these elements are arranged and their functions helps in both troubleshooting and routine maintenance tasks.

Each key element, from hydraulic cylinders to control units, serves a specific purpose in the overall operation of the machine. By learning to identify these parts in the system layout, operators and technicians can quickly assess the status of the equipment and address any issues promptly.

Familiarity with the essential components not only aids in diagnostics but also ensures that maintenance is performed accurately, avoiding unnecessary replacements and ensuring the longevity of the equipment. Recognizing the parts and understanding their relationships enhances both the safety and efficiency of machine operation.

How to Troubleshoot Aerial Equipment Components

Effective troubleshooting starts with understanding the common issues that can arise within a mechanical system. By identifying symptoms early, operators can prevent further damage and ensure the system remains operational. Knowing how to recognize and diagnose problems is crucial for maintaining equipment performance.

The first step in resolving any issue is to systematically inspect each component. Begin by checking the hydraulic and electrical systems, as these are often the source of many common malfunctions. Look for signs of wear, leaks, or loose connections, which can impact performance and safety.

Once you’ve identified the potential issue, refer to the system’s layout to understand how the components interact. This can help pinpoint the exact cause of the problem, whether it’s related to power failure, mechanical wear, or improper calibration. Regular inspection and early detection of issues can significantly reduce downtime and repair costs.