Every machine consists of numerous components working together to ensure smooth operation. Knowing how each part fits into the system can make a significant difference in performance and longevity. Understanding the layout of these elements is essential for any owner or operator aiming to maintain their equipment properly.

In this guide, we will focus on providing a detailed overview of the structure and organization of key machine elements. By breaking down the mechanics and functions, we aim to equip you with the knowledge needed for effective repairs and maintenance.

Whether you’re a novice or experienced mechanic, having a clear understanding of your equipment’s interior will help you avoid costly mistakes and improve troubleshooting efficiency. Armed with this information, you can keep your machine in top condition and ensure its continued reliability.

Understanding Key Machine Components

Every piece of equipment is made up of various components that work in harmony to ensure its functionality. Each element, from the smallest bolt to the largest engine part, plays a vital role in the overall performance of the machine. Understanding how these elements interact with each other is crucial for proper maintenance and repair.

In this section, we will explore the main components of your machine and their respective functions. By breaking down the mechanical system, you will gain insight into the critical functions of each part and how they contribute to the machine’s operation. This knowledge can be invaluable when diagnosing issues or performing routine upkeep.

Familiarizing yourself with these essential elements allows you to identify potential problems early and make informed decisions about repairs. A well-maintained machine not only performs better but also lasts longer, providing you with greater efficiency and cost savings over time.

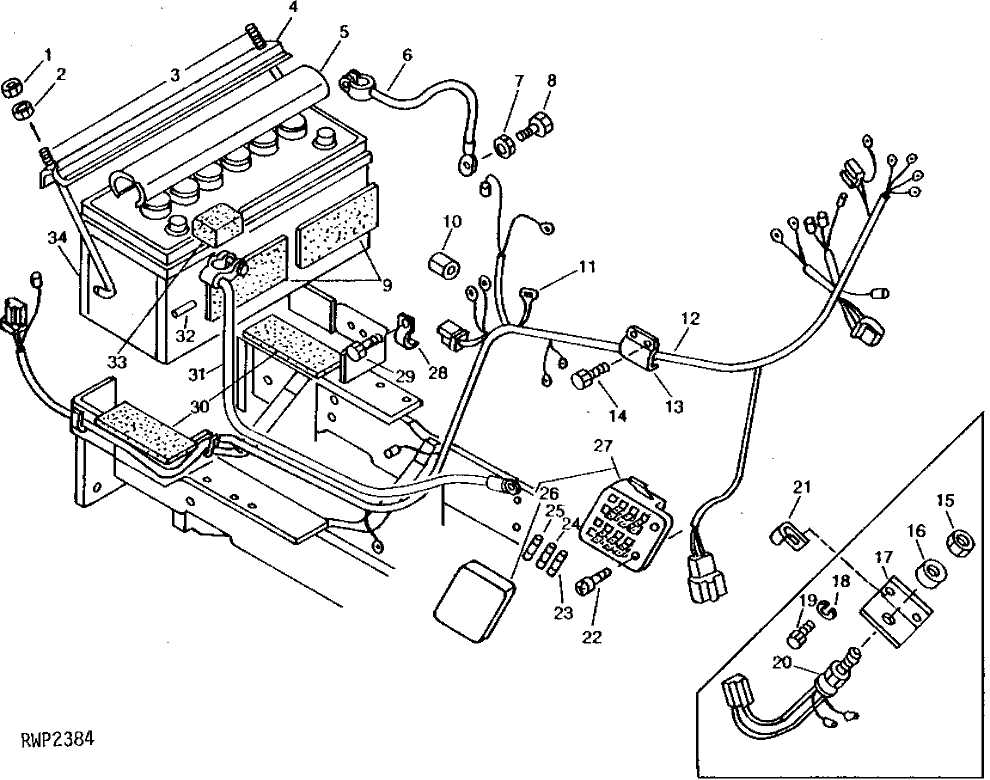

How to Read the Parts Layout

Interpreting the layout of components is essential when it comes to maintaining and repairing complex machinery. A clear and detailed illustration allows you to pinpoint specific elements, making the task of identifying issues much easier. Understanding how to read such visuals will enable you to navigate the intricate system of components efficiently.

The key to reading any component layout is to familiarize yourself with the symbols, labels, and numbering system used. Each part will be marked clearly, and it’s important to follow the lines connecting them, as these usually indicate the relationships or connections between different elements. Knowing where each part belongs in the overall structure can help in troubleshooting and repairing tasks.

Once you understand the basic structure of the layout, you can easily locate any part you need to check or replace. This knowledge helps you make informed decisions quickly, whether you’re performing routine inspections or addressing specific malfunctions. A thorough understanding of these diagrams will make any maintenance or repair task more manageable.

Common Repairs for Agricultural Equipment

Machines used in heavy-duty tasks often experience wear and tear over time, requiring periodic repairs to maintain optimal performance. Common issues can range from minor malfunctions to more significant mechanical failures. Knowing what to expect and how to address these concerns can save both time and money.

One frequent repair involves the engine, particularly addressing issues such as overheating, loss of power, or irregular performance. This can often be traced to problems with the fuel system, air filters, or even the cooling system. Ensuring that these components are clean and functioning correctly can prevent larger, more costly repairs down the road.

Another common issue is with the transmission, especially if the machine is struggling to shift gears or if there’s difficulty in engaging certain functions. Regular maintenance and fluid checks can help prevent transmission failure, which is a costly and time-consuming repair. Additionally, hydraulic systems are often prone to leaks, which can affect functionality and safety if not promptly addressed.

By staying on top of these routine repairs and addressing issues early, the longevity and reliability of the machine can be greatly improved, minimizing downtime and ensuring it continues to perform effectively.