Understanding the internal structure of your cleaning device can significantly improve its maintenance and efficiency. By recognizing the individual elements that work together, you can identify potential issues and handle repairs with ease. A detailed guide to these elements is essential for keeping your equipment in top working condition.

From motor components to filtration systems, each section plays a crucial role in the device’s functionality. Whether it’s troubleshooting a malfunction or simply ensuring everything is working as intended, having a clear understanding of the main components will make the process smoother. Knowing how to recognize these parts allows for effective care and proper adjustments when necessary.

Regular maintenance and occasional part replacements are part of owning such equipment. However, without clear knowledge of the different sections, it’s easy to miss small issues that could lead to bigger problems down the line. This guide will help you identify the key areas for a deeper understanding of your device’s structure.

Understanding Key Components of Your Cleaning Device

Every cleaning appliance consists of various elements that work together to ensure smooth operation. By recognizing these individual components, users can gain better insight into how the machine functions and what may need attention over time. A solid understanding of each section helps with troubleshooting, maintenance, and ensuring longevity.

The most vital components include the motor, filtration system, and the movement mechanisms that power the machine. Each of these plays a significant role in performance and efficiency. Knowing how to identify and care for these elements is essential for maintaining peak performance and extending the lifespan of the equipment.

Regular cleaning, replacing worn-out parts, and checking for any signs of damage are key to keeping the device functioning as it should. Familiarizing yourself with these elements will help you identify potential issues before they escalate into larger problems, saving time and money in the long run.

How to Identify Key Parts in Your Cleaning Equipment

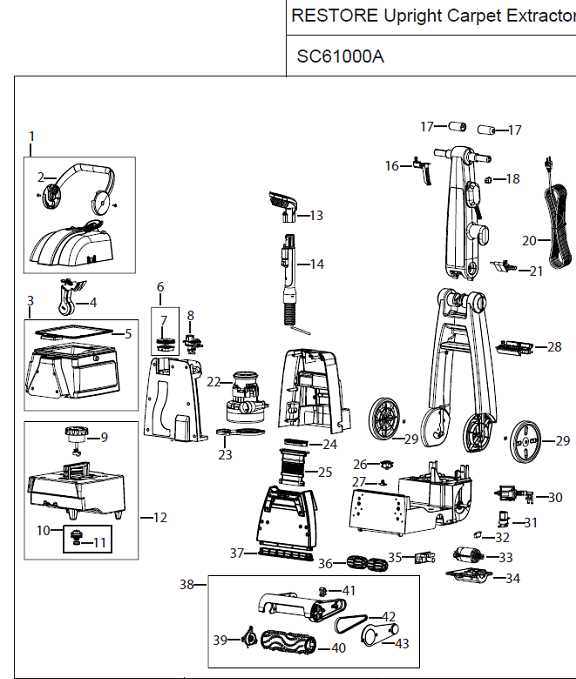

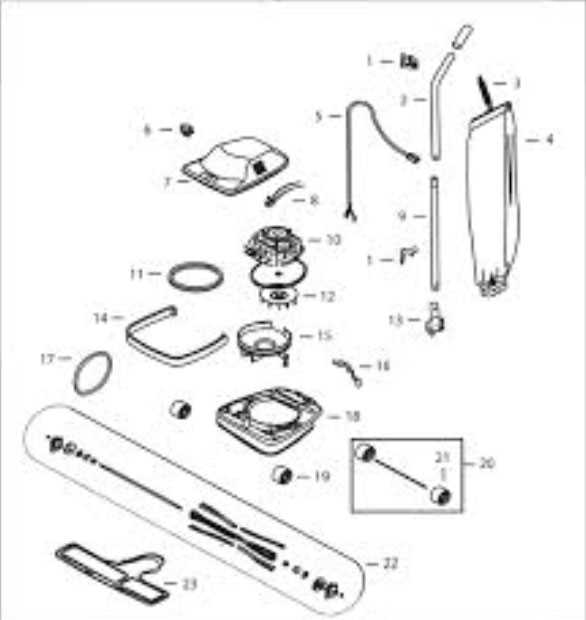

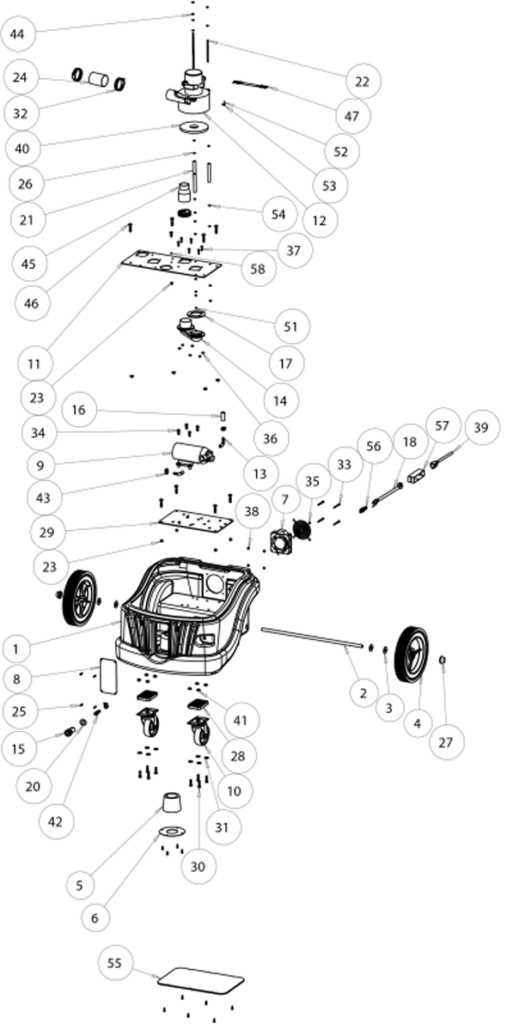

Recognizing the individual elements that make up your cleaning device is essential for effective maintenance and troubleshooting. Knowing where each component is located and understanding its function helps ensure the equipment operates smoothly. This knowledge is crucial whether you’re performing regular checks or addressing specific issues.

The most significant sections include the motor assembly, the filtration unit, and the collection container. These components are responsible for the main functions of the machine and directly affect its performance. Understanding their location and how they interact with other parts can make it easier to identify problems early on.

To identify these parts, start by referring to the user manual, which often provides clear visual references. Familiarize yourself with the appearance and placement of each part, and regularly inspect them for signs of wear or damage. Knowing how to quickly identify these elements will enable you to act promptly and avoid unnecessary repairs.

Common Issues and Fixes for Cleaning Equipment Components

Over time, your cleaning device may encounter various problems due to wear and tear. Understanding the most frequent issues and how to resolve them can prevent prolonged downtime and costly repairs. By addressing these common problems early, you can maintain optimal performance and extend the life of your equipment.

One of the most frequent issues is reduced suction power, often caused by blockages in the filtration system or hose. Regularly inspecting and clearing debris from these areas can restore full functionality. Replacing filters when they become clogged can also help improve air flow and efficiency.

Another common problem is motor malfunction, which can result from overheating or electrical issues. If the motor stops working or produces unusual noises, it is important to check for obstructions and ensure that the device is properly ventilated. In some cases, cleaning the motor and ensuring all connections are secure can solve the issue. If the problem persists, it may be necessary to consult a professional for repairs.