Understanding the layout and structure of heavy machinery is crucial for proper maintenance and repair. By familiarizing yourself with the individual components and how they fit together, you can ensure efficient functioning and extend the life of your equipment.

Having a detailed representation of all the key elements allows technicians to quickly identify issues, plan repairs, and replace worn-out parts with ease. This approach minimizes downtime and reduces costly mistakes, making maintenance processes smoother and more reliable.

Accurate knowledge of each component’s location and function is essential for preventive care and effective troubleshooting. With the right resources, maintenance tasks become much more straightforward, saving time and effort.

Understanding the Equipment Layout

Gaining a clear understanding of the machinery layout is fundamental for anyone involved in its maintenance. By visualizing the entire system, from its core components to individual units, users can quickly pinpoint potential issues and address them efficiently. A comprehensive view helps to grasp the overall functioning and ensures smoother operation.

Components and Their Functions

Each element within the system has a specific role, contributing to the machine’s overall performance. Identifying these components allows for better insight into how they interact with each other and how wear and tear may affect their functionality over time. Proper knowledge helps in preventing failure before it occurs.

How to Interpret the System Layout

Understanding how to read and interpret the machine’s layout is essential for proper maintenance. These representations provide a visual map of the equipment, aiding in recognizing the placement of components and understanding their connections. Knowing this makes troubleshooting much more effective and ensures accuracy in repairs.

Essential Components of the Equipment

Every piece of machinery consists of a variety of crucial elements that work together to ensure efficient operation. Each of these components has a specific role, contributing to the overall performance of the system. Understanding these key parts is essential for anyone looking to maintain or repair the machine.

Power System

The power system is at the heart of the machinery, providing the necessary energy to drive all other functions. This includes the engine, fuel components, and electrical systems. A malfunction in any part of the power system can significantly disrupt the equipment’s ability to perform its tasks.

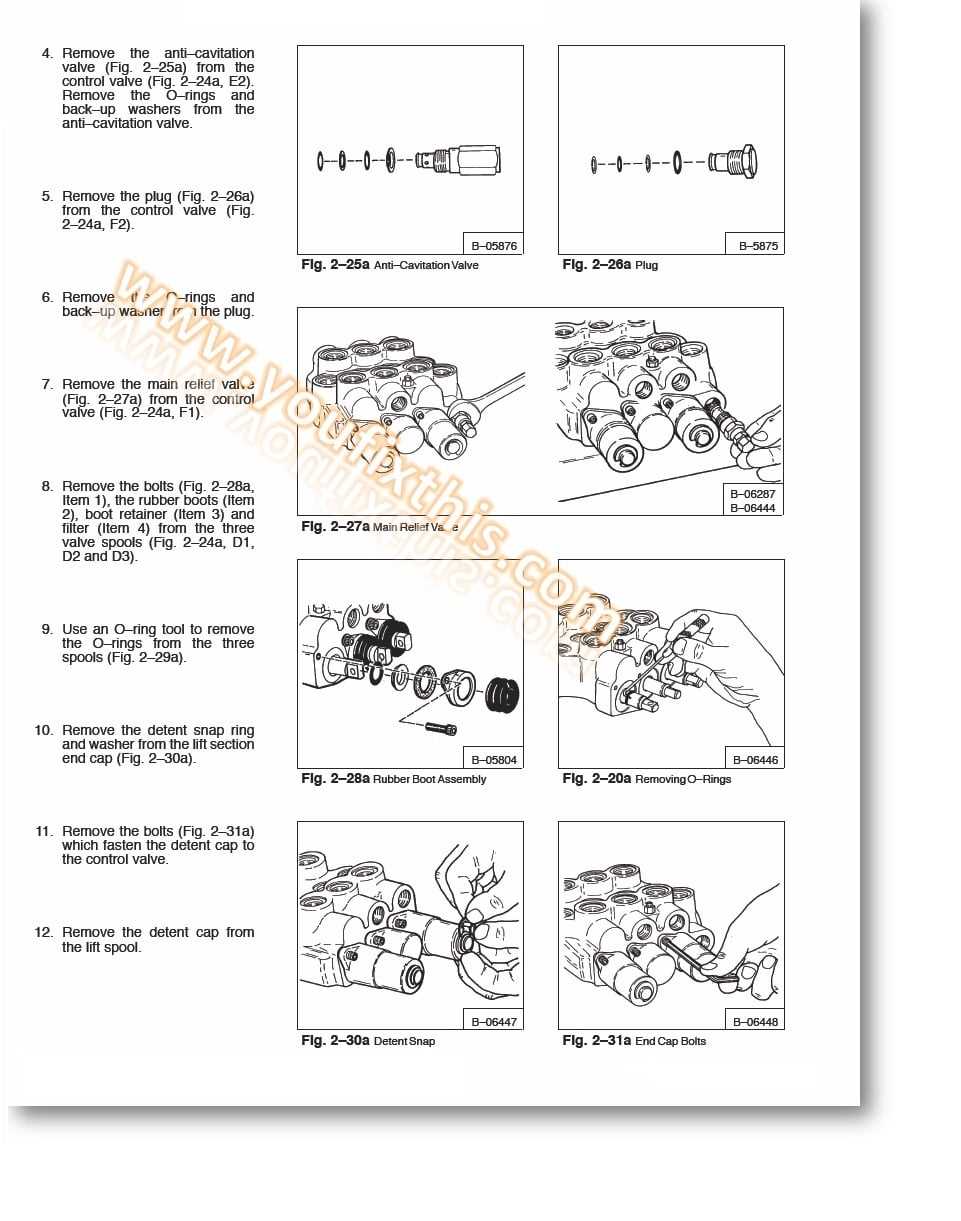

Hydraulic Components

Hydraulics play a vital role in controlling the movement of various parts of the machine, such as the lifting arms and buckets. These components rely on fluid power to operate, making it essential to ensure proper maintenance of the hydraulic system to avoid leaks or pressure failures that could lead to reduced efficiency.

How to Use the Equipment Layout Effectively

Utilizing a comprehensive layout representation of a machine is an essential skill for efficient maintenance and repair. By understanding how to read and interpret the layout, users can easily locate specific components, identify potential issues, and streamline the troubleshooting process.

Familiarize Yourself with Key Areas

Before diving into repairs or maintenance, it is important to identify the key sections of the machine. Understanding which components are critical to the overall operation will help you focus on the most important areas first. This knowledge helps prioritize tasks and ensures efficient use of time during maintenance.

Follow the Flow of the System

To ensure accurate repairs, it is vital to understand how the different components interact with one another. Pay attention to how the parts are connected and how energy or fluids move through the system. This will help in identifying the source of any issues and determining the most effective repair strategy.