When working with outdoor machinery, understanding its structure and individual elements is crucial for proper maintenance and repair. Whether you are assembling a new unit or troubleshooting an existing one, a clear reference to its internal components can make the process much simpler.

Accurate identification of each part allows you to efficiently locate any issues, saving both time and effort. Visual guides serve as essential tools for this purpose, offering a comprehensive view of how all parts interact and fit together within the machine.

By familiarizing yourself with these visual references, you can ensure that every component is correctly assembled and maintained, leading to improved performance and longevity of your equipment. This guide will walk you through understanding the essential parts and how to use such resources to keep your machine running smoothly.

Understanding Equipment Component Layout

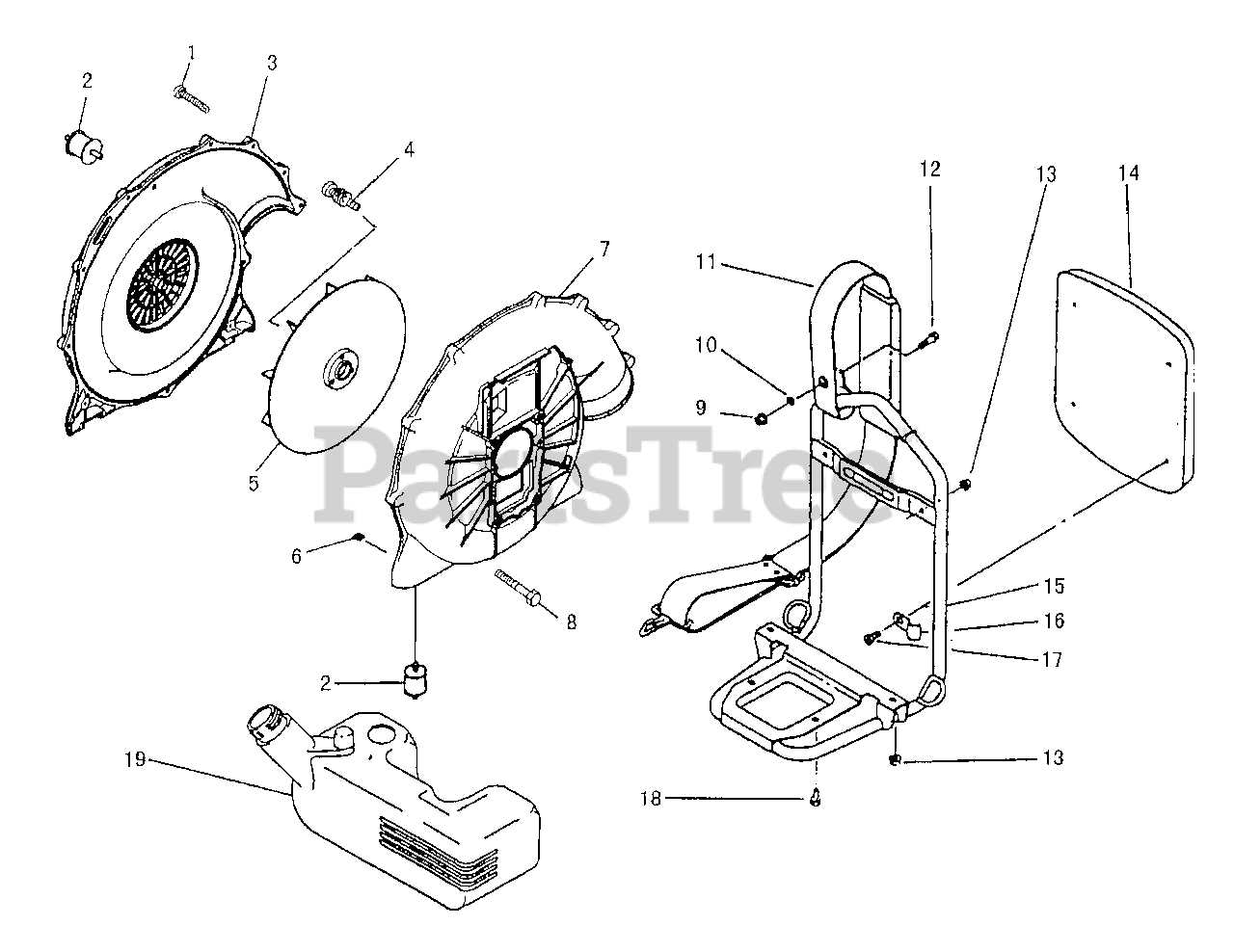

Every machine is a carefully designed system where each individual element plays a key role in its overall functionality. A clear understanding of how all components are arranged and connected can greatly enhance both maintenance and repair processes. By learning how these elements are distributed across the machine, you can better navigate any repair or assembly task.

Identifying the arrangement of critical components is essential for diagnosing any performance issues. Knowing where each part fits into the larger structure allows for faster troubleshooting, ensuring that no aspect of the machine is overlooked. This clarity is especially useful when dealing with complex systems, where a slight misalignment can affect performance.

In order to maximize the lifespan and efficiency of your equipment, it’s important to familiarize yourself with its component layout. Proper understanding leads to informed decisions when performing maintenance, making it easier to spot worn-out or faulty parts. This section will provide you with the knowledge needed to interpret the layout of the unit and keep it in top working condition.

Identifying Key Parts of the Machine

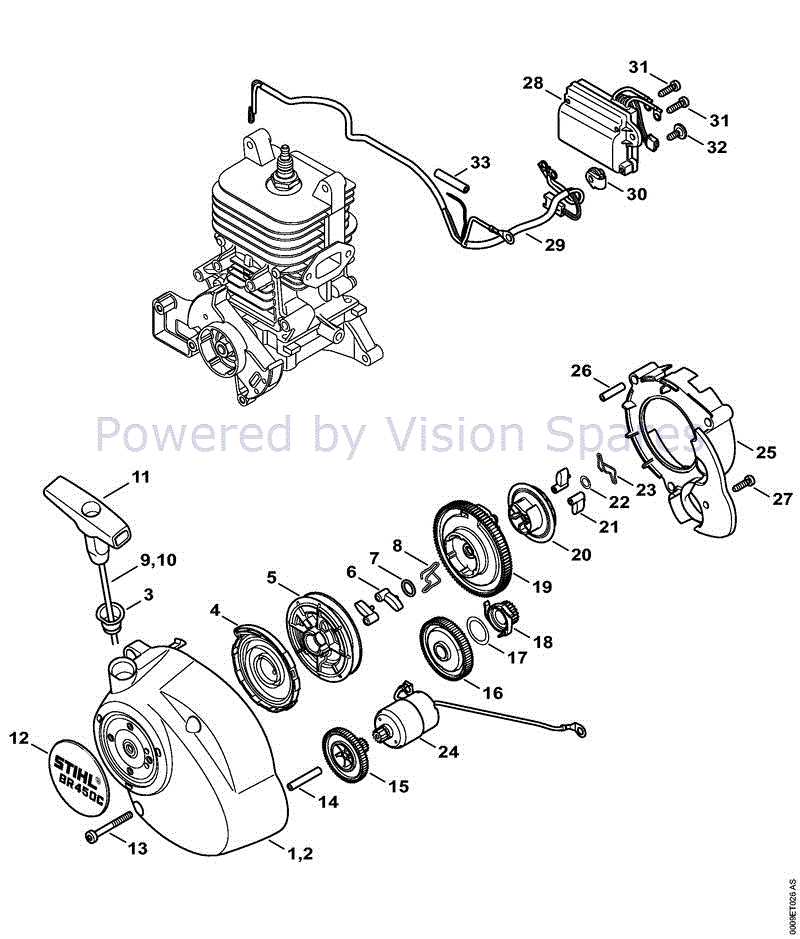

Every mechanical unit consists of essential components that are critical for its operation. Recognizing these key elements ensures that users can efficiently maintain and repair the equipment when necessary. Knowing where each piece fits within the assembly allows for better understanding and smoother troubleshooting.

Some of the most important sections include the engine, fuel system, and power transmission elements. These components are the heart of the machine and play vital roles in its performance. Understanding how each part functions and interacts with the others provides a clearer picture of the overall system.

Additionally, regular identification of worn or damaged components can prevent breakdowns and prolong the lifespan of the equipment. This section aims to help you pinpoint the most important elements and guide you through the process of recognizing them in any reference materials you may use.

How to Use the Parts Diagram Effectively

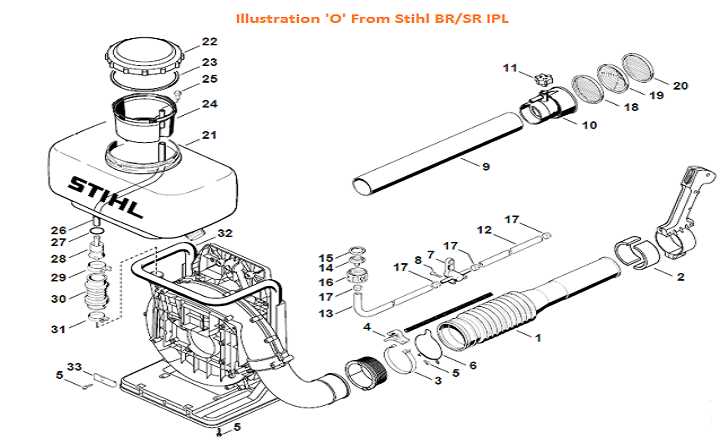

A well-organized visual guide can significantly simplify the process of understanding the structure of any equipment. When working with complex machinery, using a reference tool to identify and locate each component ensures accuracy and efficiency. The key is to approach the guide systematically and with attention to detail.

Understanding the Layout

The first step is to familiarize yourself with the layout of the guide. Pay close attention to how the components are grouped and labeled. Each section usually follows a logical progression that corresponds to the actual assembly of the machine. By understanding the general layout, you can more easily find the specific part you need.

Using the Guide for Maintenance and Repairs

Effective use of the reference tool involves more than just identifying parts–it’s about knowing how to troubleshoot and make repairs. For maintenance tasks, cross-check the reference against the physical equipment to ensure correct part placement. When repairing, identify any damaged or worn parts and replace them with precision using the guide as your roadmap.

By mastering the use of such visual resources, you can streamline maintenance processes and avoid unnecessary mistakes. Properly interpreting the guide not only saves time but also enhances the lifespan of the machinery.