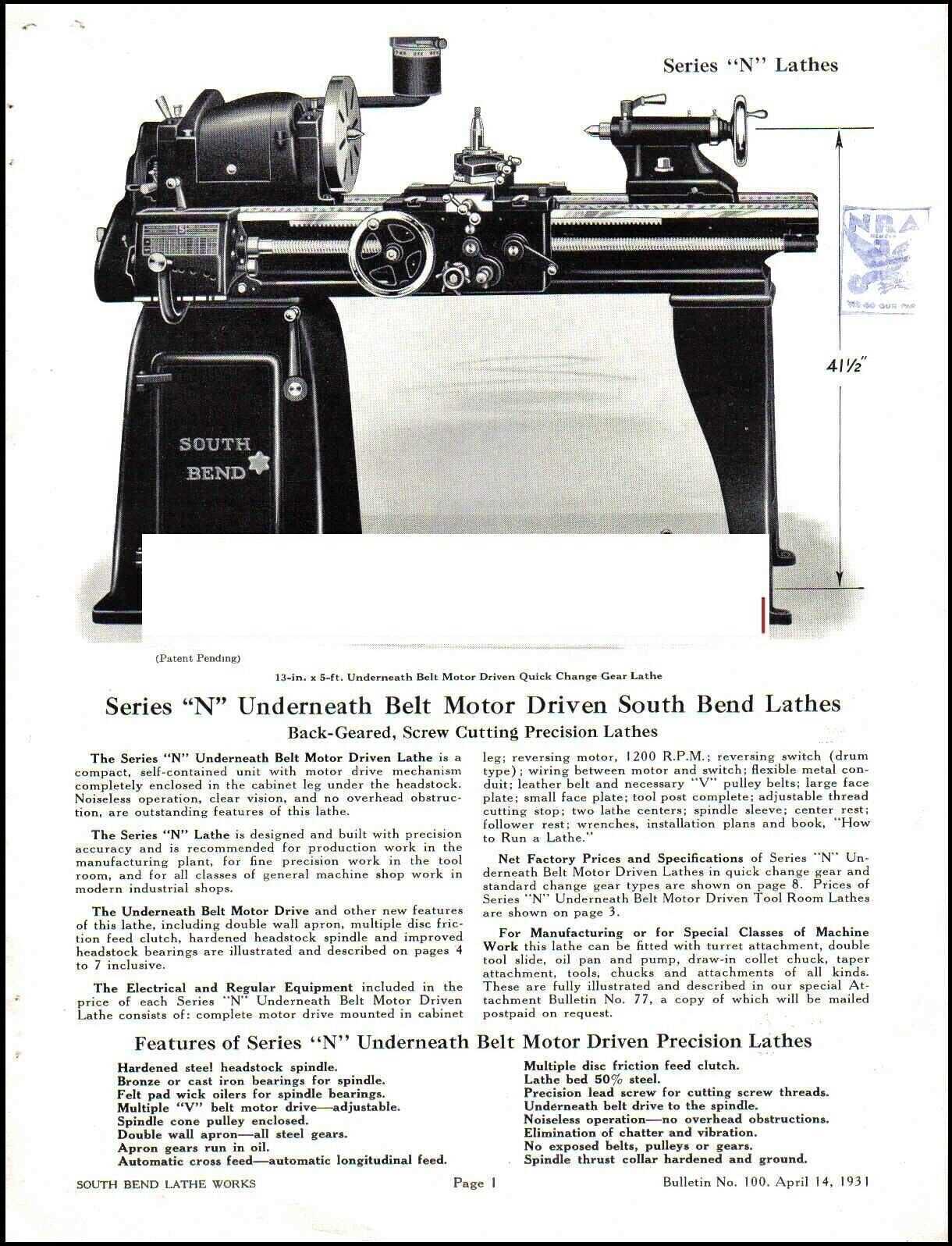

Every mechanical tool is made up of several intricate parts working together to achieve its function. To ensure smooth operation, it’s crucial to understand how these components interact. By familiarizing yourself with the layout and structure of the tool, you can better maintain, repair, and optimize its performance.

Knowing the essential elements of your equipment helps in troubleshooting and making informed decisions when it comes to maintenance or upgrades. This knowledge can significantly extend the lifespan of the tool and improve its efficiency.

Whether you’re a beginner or an experienced user, having a clear view of the machine’s build is an essential skill. It allows you to identify each section and part quickly, helping to avoid errors during repairs or adjustments.

Understanding South Bend Lathe Components

The functionality of any machine depends on the seamless cooperation of its individual sections. Each component plays a crucial role in ensuring that the overall system performs as expected. In order to make the most of your equipment, it is essential to understand the function and position of every major element.

Knowing the key elements of your tool helps in identifying potential issues early and addressing them before they escalate. Understanding the function of each section allows for more efficient use and reduces the risk of damaging the machine during operations.

Recognizing the interconnection of these different components is crucial for successful maintenance and upgrades. When you know how each part supports the others, you can make precise adjustments that improve the machine’s overall performance and longevity.

Key Parts of the Lathe Machine

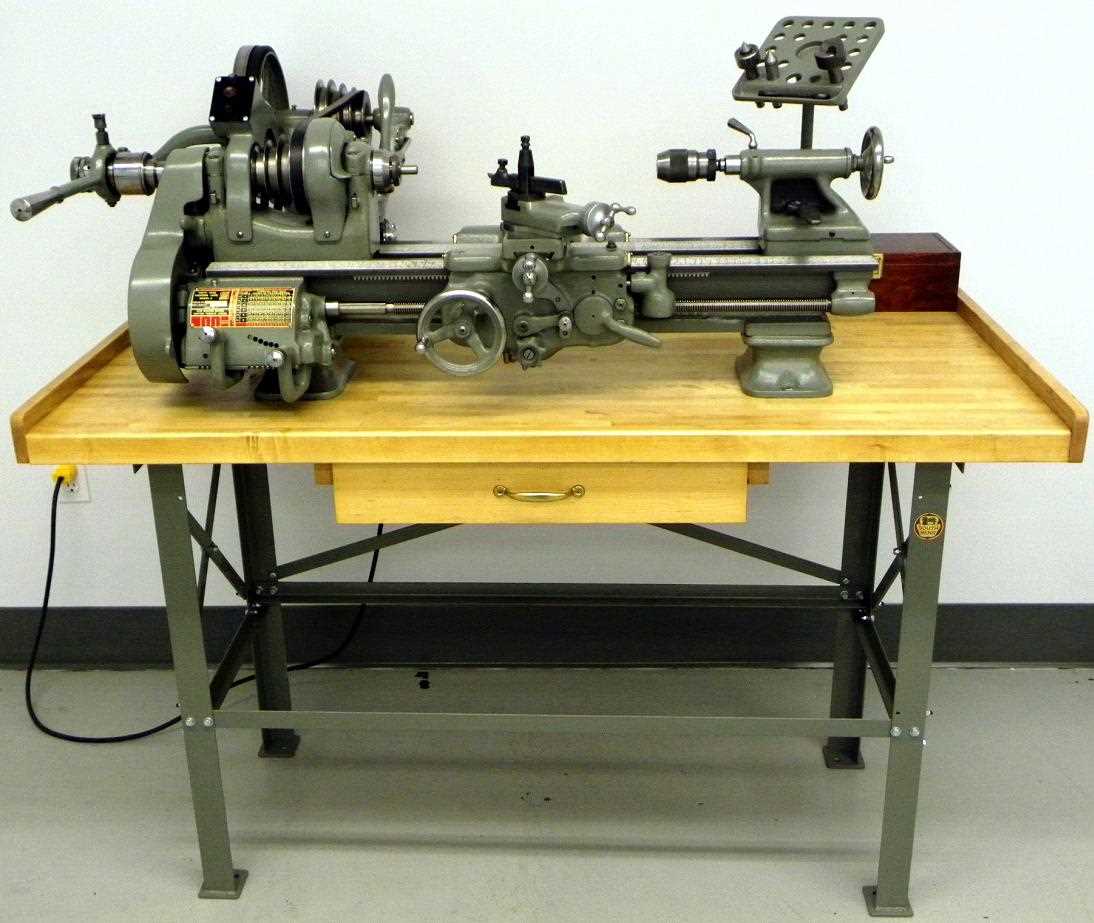

Understanding the main elements of a machining tool is essential for anyone looking to operate or maintain it effectively. These crucial components work together to ensure the machine functions smoothly and accurately. Familiarizing yourself with these pieces allows for proper operation and efficient troubleshooting.

Essential Operating Components

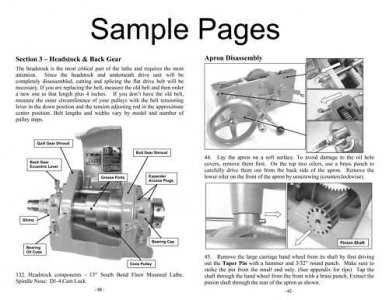

At the core of the system are the drive mechanisms, which provide the necessary motion for cutting or shaping materials. These include the motor, gears, and other motion-transmitting sections that enable precise control over the material being worked. The bed and carriage also play a significant role in supporting the entire structure and guiding movement during operation.

Control and Adjustment Elements

Several elements are involved in the control and fine-tuning of the machine’s functionality. These include handles, knobs, and other manual interfaces that allow the operator to adjust speed, feed rate, and tool positioning. Understanding how these components interact ensures that the machine is used at its full potential without compromising accuracy.

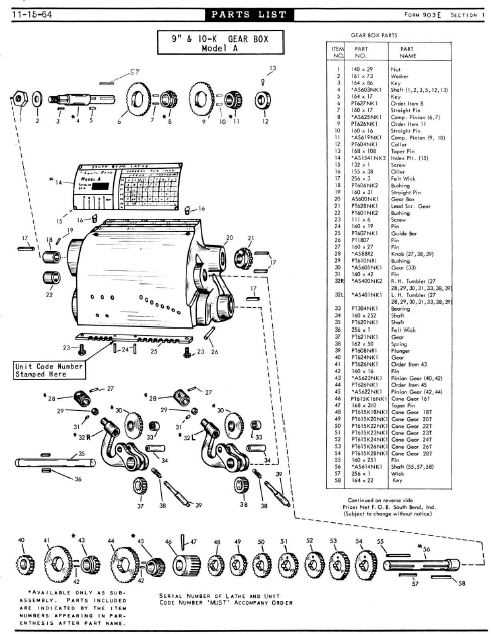

How to Use the Parts Diagram

Knowing how to effectively utilize the layout of a machine is essential for maintenance, repair, and optimization. A detailed map of the equipment’s structure provides an invaluable reference, enabling operators to quickly identify components and their roles. This guide helps you understand how to read and interpret these layouts to work more efficiently.

Step-by-Step Analysis

Start by locating the most prominent sections of the tool. These are usually the base and key moving components. Focus on understanding how the major units are connected and how their movements affect the operation. Understanding this connection is critical for troubleshooting or replacing worn-out sections.

Identifying Specific Components

Once you’re familiar with the broader structure, dive into smaller components. Look for highlighted areas or parts that are more critical to performance. This focused examination helps in pinpointing exact areas that need attention, making your repairs more targeted and effective.