Understanding the key elements that make up a compact agricultural machine is crucial for effective maintenance and smooth operation. Each section plays a unique role in ensuring optimal performance, and knowing how they fit together helps avoid potential issues. With the right knowledge, owners can tackle troubleshooting tasks with confidence and efficiency.

Identifying individual components and understanding their interconnections are essential when it comes to repairs or upgrades. Familiarity with the layout can simplify the decision-making process and help locate parts that may need attention. Knowing where each part is situated ensures faster repairs and reduces downtime.

Proper maintenance starts with being able to pinpoint each component’s function. Whether it’s replacing worn-out pieces or performing routine checks, understanding how everything works together is vital for extending the machine’s lifespan and avoiding costly repairs. This guide will assist you in mastering the layout of your tractor, enabling better care and usage.

Understanding the Tractor Components

Every agricultural machine is built with a specific set of elements that work together to ensure its functionality and efficiency. Recognizing the role of each section is key to effective maintenance and troubleshooting. A well-rounded understanding of these components allows for easier detection of issues and a smoother repair process.

Each part has its own purpose, from those responsible for power distribution to those ensuring proper mobility. Familiarity with these sections enables a better grasp of how they interact with one another to produce the desired output. By knowing where each item is located, one can efficiently handle maintenance tasks, minimize downtime, and improve overall performance.

Being able to distinguish between the different components also aids in understanding which ones may need replacement over time. Regular checks and keeping track of the wear on these elements help ensure the machine remains in good working condition for longer periods, preventing costly breakdowns and enhancing the user experience.

Key Components and Their Functions

Understanding the core sections of a compact agricultural machine is essential for its optimal use and maintenance. Each element serves a distinct purpose, contributing to the overall performance and efficiency of the machine. Recognizing how these parts interact is crucial for identifying potential issues and carrying out effective repairs.

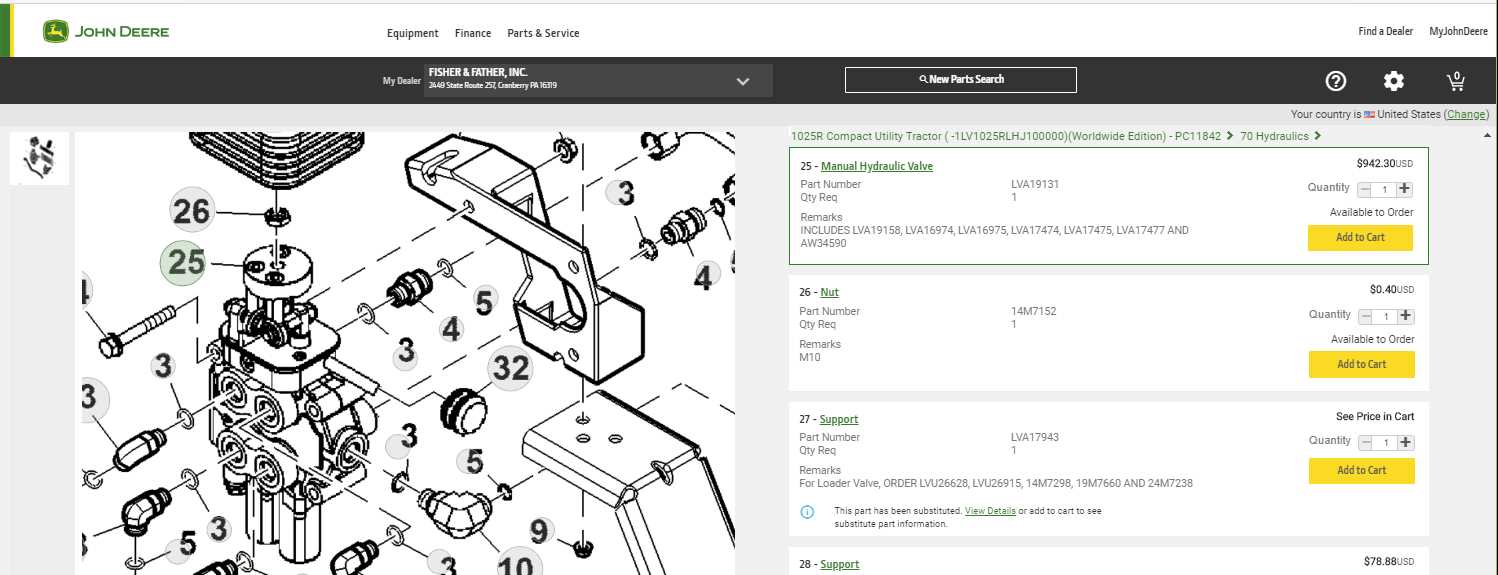

One of the most vital sections is the engine, which provides the necessary power to drive various functions, including movement and lifting. The hydraulic system is equally important, controlling attachments and ensuring smooth operation for tasks such as digging or lifting materials. The transmission ensures that power from the engine is properly distributed to the wheels or tracks, allowing for smooth motion and maneuverability.

Additionally, the cooling system plays a crucial role in preventing overheating, maintaining the machine’s performance during extended use. The electrical system connects all the necessary components for communication and control, powering lights, signals, and operational systems. Properly understanding these components allows for more efficient maintenance and helps extend the lifespan of the equipment.

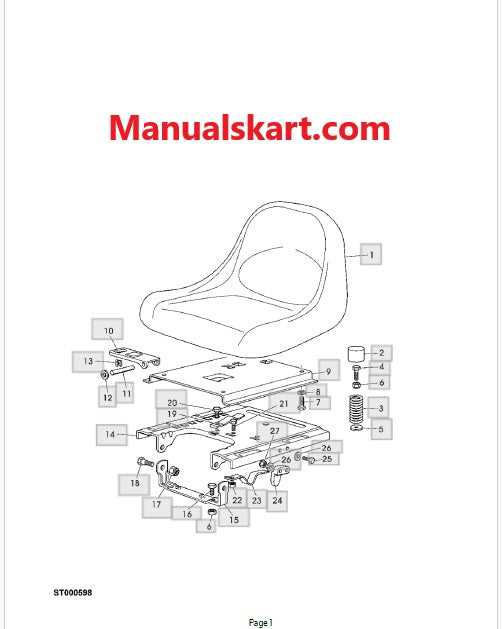

How to Use the Parts Diagram

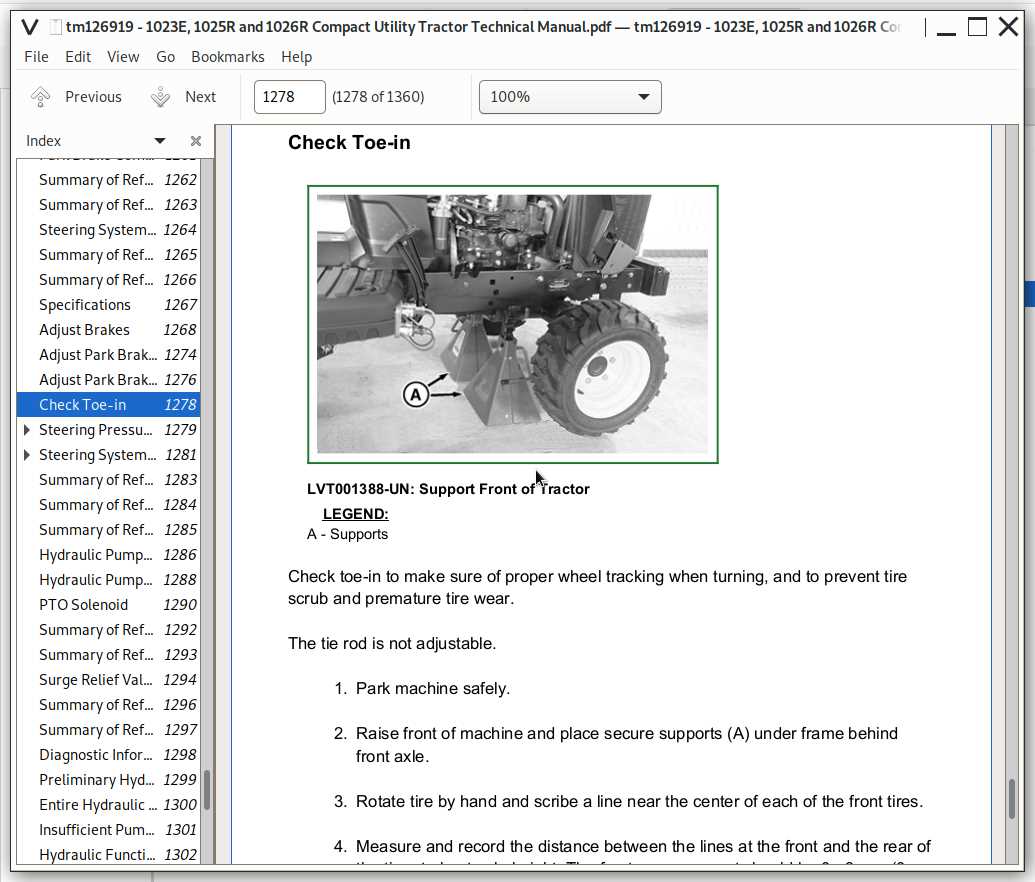

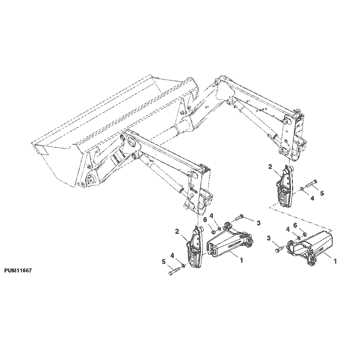

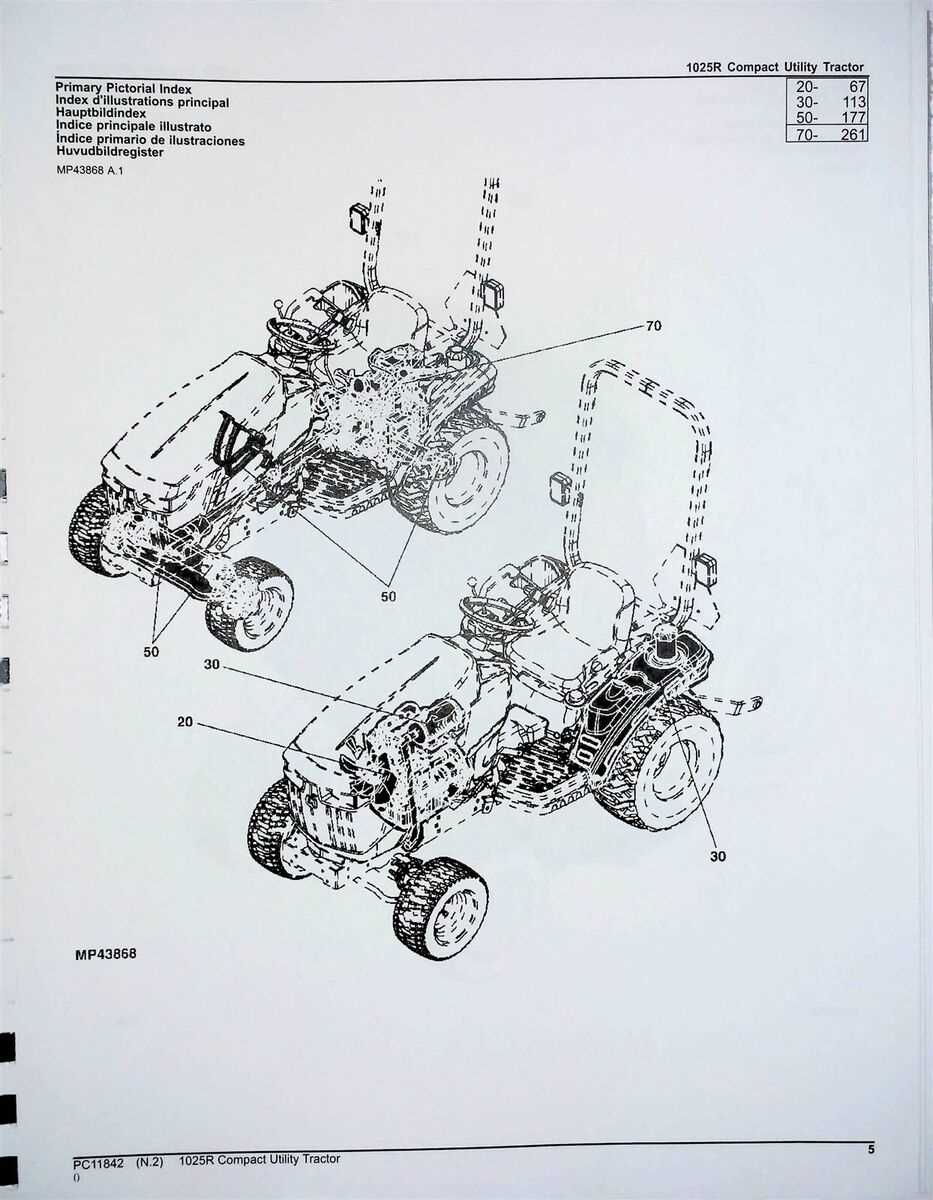

Understanding how to navigate through the layout of a machine’s components is essential for effective maintenance and repair. A visual guide offers a clear representation of where each piece is located and how they interact with one another. By utilizing this guide, users can quickly identify specific sections that require attention.

To begin, it’s important to recognize the overall structure of the diagram, noting the labels and sections corresponding to different components. Each area will typically show a numbered or labeled identification that refers to a specific part. Familiarizing yourself with these labels helps pinpoint the part in question without confusion.

Once you have identified the necessary section, you can reference the guide to locate replacement items or tools needed for repairs. This approach not only speeds up the process but also ensures that the right components are used for the job. A thorough understanding of the visual layout minimizes errors and helps maintain the functionality of the machine.

Common Issues and Maintenance Tips

Like any mechanical equipment, compact agricultural machines are prone to certain issues over time. Recognizing these common problems early can prevent more serious damage and reduce repair costs. Regular upkeep is essential to keep the machine running smoothly and extend its lifespan.

One of the most frequent issues is engine overheating. This can be caused by a variety of factors such as clogged cooling systems or low coolant levels. To avoid overheating, ensure regular maintenance of the cooling system and check fluid levels frequently.

- Engine Oil: Change the oil at recommended intervals to maintain optimal engine performance.

- Air Filters: Clean or replace air filters regularly to ensure proper airflow and prevent engine strain.

- Hydraulic System: Check hydraulic fluid levels and inspect for leaks to avoid malfunction in attachments.

Another common issue is transmission problems, which can lead to reduced mobility and uneven movement. To minimize wear and tear on the transmission, follow proper operating procedures and avoid overloading the machine. Regularly inspect the belts and gears to ensure proper alignment and function.

- Belts: Inspect belts for wear and replace if they show signs of cracking or fraying.

- Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent premature damage.

By addressing these concerns early and following a consistent maintenance schedule, you can ensure the continued performance of your equipment and avoid costly repairs in the long run.