Proper knowledge of your machine’s internal structure is essential for effective maintenance and repair. Knowing how each element works together helps ensure smooth operation and longevity. Identifying components and understanding their roles is crucial for anyone looking to keep their equipment in optimal condition.

Visual guides are invaluable tools when it comes to recognizing and understanding the layout of a complex system. These references provide clarity, helping to pinpoint specific parts and their functions. With a clear illustration, even intricate mechanical systems become easier to navigate.

Regular upkeep is vital for avoiding costly breakdowns and extending the lifespan of your machinery. By becoming familiar with each element, you can troubleshoot issues faster and perform repairs with greater confidence. Staying proactive with maintenance keeps your equipment running smoothly and efficiently.

Understanding Key Machine Components

Knowing the different elements that make up a machine is crucial for anyone responsible for its maintenance and functionality. Each component plays a specific role, and understanding how they interact can help you manage the equipment more effectively. Familiarity with the key sections allows for quicker diagnostics and smoother repair processes, minimizing downtime.

Major Components and Their Functions

At the core of every mechanical system are the essential parts that keep everything working in unison. These components include the engine, transmission, and drivetrain, each serving a vital purpose in ensuring the equipment operates efficiently. Understanding their role in the overall system helps you identify potential issues before they become major problems.

Maintenance and Troubleshooting Tips

Once you understand how each part functions, regular maintenance becomes simpler. Knowing what to check and when to replace parts reduces the likelihood of sudden malfunctions. Keeping track of wear and tear, lubrication, and component alignment is crucial for prolonging the machine’s lifespan and keeping it running at peak performance.

How to Read a Parts Diagram

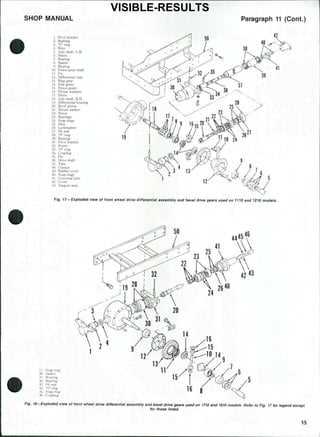

Understanding visual references is essential when working with complex machinery. These illustrations serve as a guide, breaking down the intricate layout of components and their relationships. By learning how to interpret these detailed visuals, you can identify each part, its placement, and how it functions within the overall system.

Identifying Key Symbols and Labels

Each visual guide typically includes various symbols and labels that represent specific components. Symbols are used to simplify the identification of parts, while labels often include numbers or codes that help you pinpoint the exact location and specifications. Understanding these elements is the first step in making sense of the entire reference.

Following the Layout for Effective Maintenance

Once you familiarize yourself with the symbols and labels, the next step is to follow the layout carefully. The layout often shows the arrangement of components in a logical order, helping you understand the flow of the system. By following the diagram, you can better plan for repairs and maintenance tasks, ensuring you address all necessary areas.

Essential Components for Machine Maintenance

Regular upkeep of any mechanical system requires attention to the key elements that keep it running smoothly. Identifying and maintaining these critical components ensures optimal performance and extends the machine’s lifespan. Knowing which parts need frequent checks and care helps prevent major breakdowns and costly repairs.

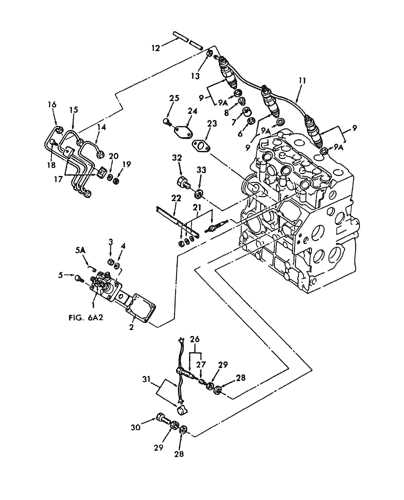

Critical Engine and Transmission Components

The engine and transmission are among the most vital elements to monitor closely. The engine provides the necessary power, while the transmission ensures that power is properly transferred to the wheels or other moving parts. Proper lubrication and regular checks of these systems are essential for keeping the machine running without interruptions.

Drive System and Hydraulic Components

In addition to the engine and transmission, the drive system and hydraulic components play a crucial role in maintaining smooth operation. These systems are responsible for the movement of the machine and the control of various attachments. Keeping the hydraulic fluid levels in check and ensuring proper alignment of the drive system helps avoid mechanical issues during operation.