In any thermal energy generation unit, various components play distinct roles in ensuring efficient operation. Each of these elements interacts with others to produce the desired effect while maintaining safety and reliability. A clear understanding of their layout and function is essential for optimizing performance and extending the lifespan of the system.

Main Functional Units

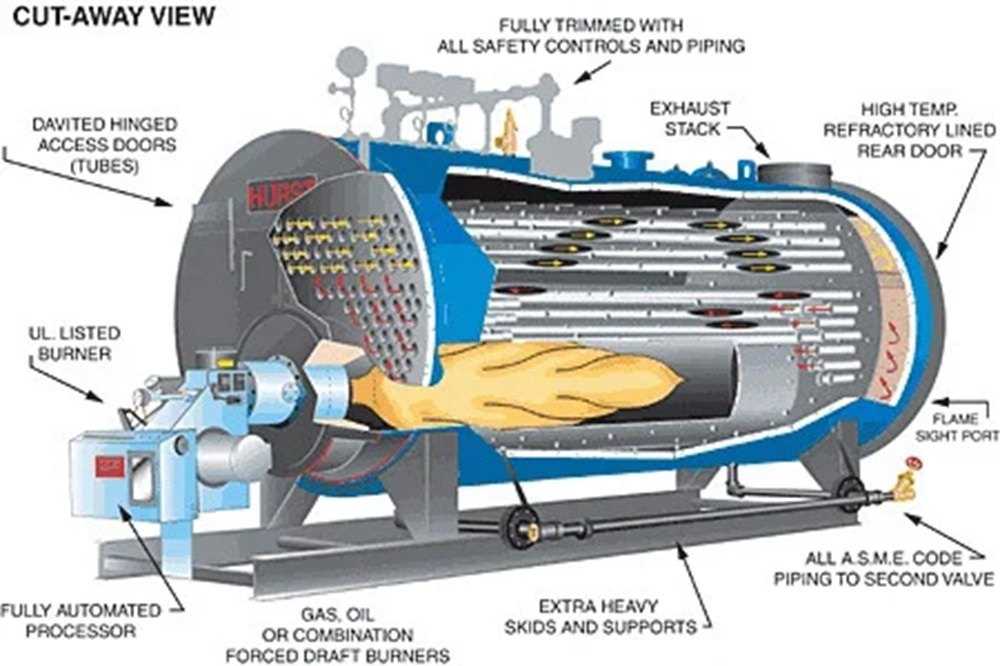

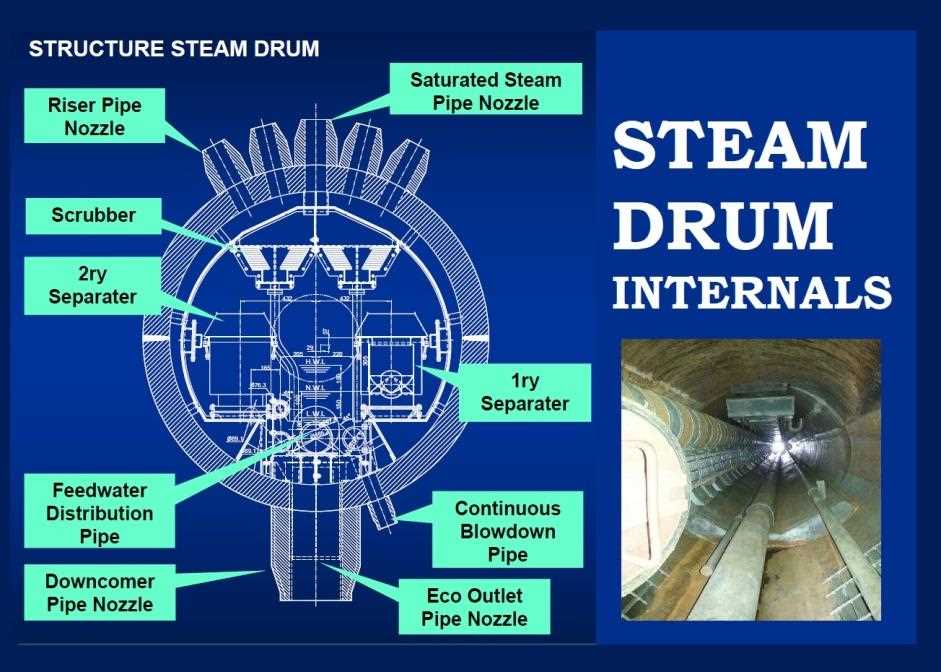

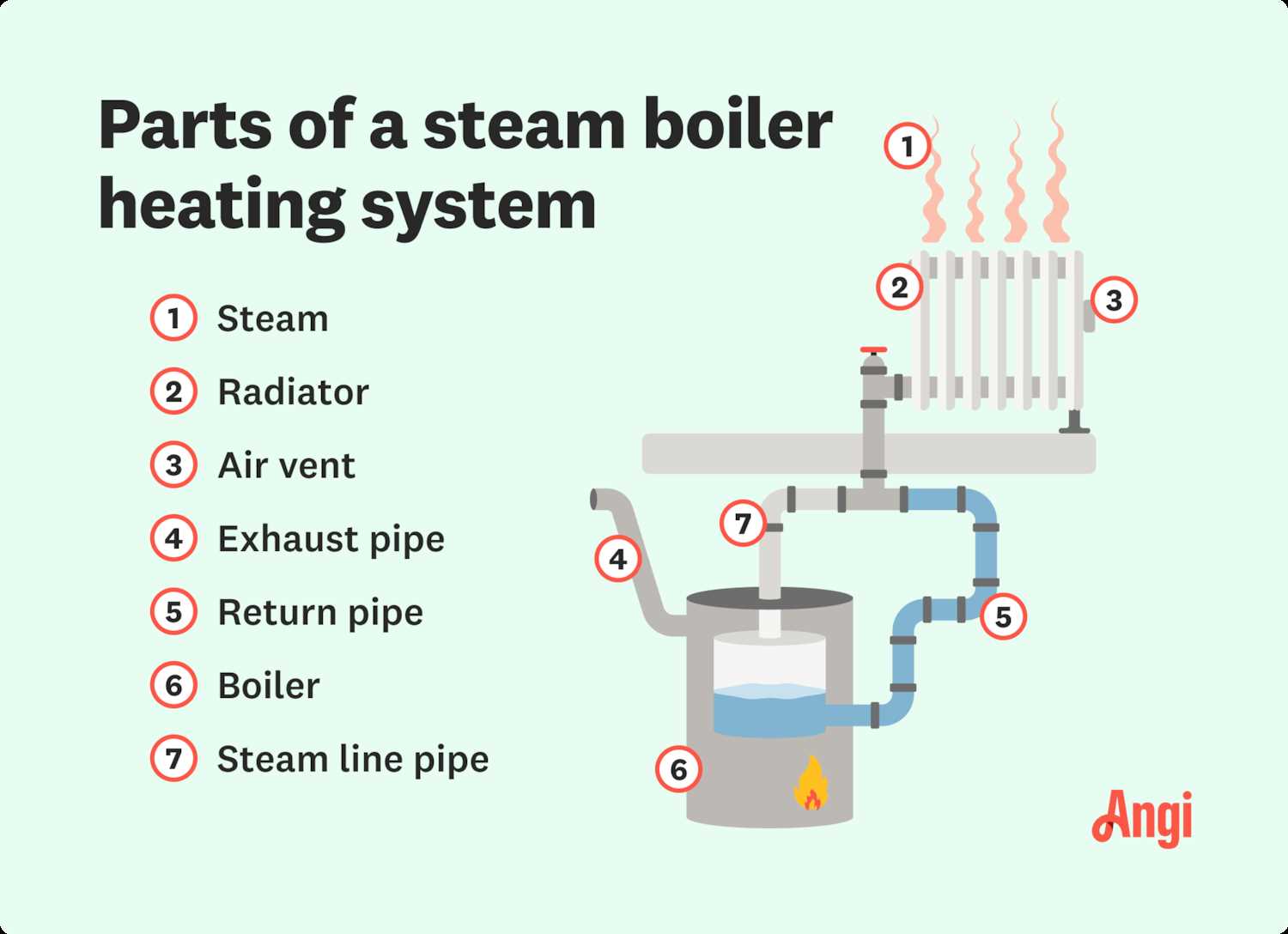

The core of any heating mechanism relies on multiple units that work harmoniously. These typically include the combustion chamber, heat exchangers, pressure regulators, and safety valves, all contributing to the system’s overall performance. Proper coordination between these components ensures effective energy transfer and minimal wastage.

Heat Exchange and Transfer

Efficient heat exchange is critical in any setup designed for thermal energy conversion. The heat exchanger facilitates the transfer of heat from the source to the surrounding medium, ensuring energy is utilized efficiently. The flow of heat depends on the design and materials used in these parts, which directly impacts overall effectiveness.

Control and Regulation Mechanisms

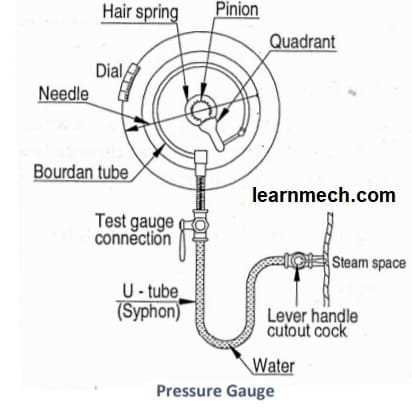

Another key aspect is the control systems that monitor and adjust various parameters such as pressure, temperature, and flow rates. These mechanisms ensure that the system operates within safe limits while adapting to changing demand. The regulator valves and sensors are pivotal in this regard.

Safety Considerations

For any unit designed for high-temperature or pressurized environments, safety is paramount. Various safety valves and shutdown mechanisms are in place to prevent catastrophic failures. These elements are essential for protecting both the equipment and the operators.

Preventive Maintenance

Regular inspection and maintenance are critical to ensure that all components function properly. Identifying wear and tear early can prevent costly repairs and ensure uninterrupted service. Scheduled maintenance checks are necessary to keep the system running at peak efficiency.

Identifying Potential Issues

Being able to recognize early signs of malfunction in any element is crucial. Indicators like unusual noises, changes in pressure, or fluctuating temperatures often signal that a component may need attention. Addressing issues promptly can prevent further damage and maintain system integrity.

Key Components of a Heating System

In any thermal energy unit, there are crucial elements that contribute to the overall functionality and efficiency. These components work together to ensure proper heating, regulation, and safety during operation. Understanding the configuration and interaction between these elements is key to achieving optimal performance.

Understanding the Layout

The layout of a heating mechanism is designed for maximum efficiency, with each part playing a specific role. The main structures include heat exchangers, pressure regulators, and control units, all of which are arranged to ensure smooth operation. The arrangement of these units determines how effectively energy is harnessed and distributed throughout the system.

Internal Operation and Function

Internally, the heating unit operates through a series of processes that convert energy into usable heat. Heat transfer occurs in designated sections, while pressure regulation is managed by key safety valves and sensors. The flow of energy is monitored and adjusted to ensure that all components perform optimally, balancing power output with safety requirements.

Roles of Different Units

Each unit within the system has a specific function, from initiating the energy conversion process to maintaining temperature consistency. The control unit oversees the temperature and pressure, while safety valves protect against malfunctions. Proper coordination ensures that the system operates without interruption and within safe parameters.

Significance of Regular Checks

Routine inspection and upkeep of all components are essential for extending the lifespan of the system and preventing breakdowns. Regular maintenance helps detect potential issues early, allowing for corrective measures before they lead to significant damage. Timely service and checks ensure that the system operates at peak efficiency for longer periods.